Preparation method of calcium carbonate composite powder with visible light catalytic activity

A composite powder and catalytic activity technology, applied in the field of photocatalysis, can solve the problems of calcium carbonate having no catalytic performance, complex preparation process, limited application scope, etc., and achieve easy large-scale production, simple preparation process, and low experimental cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) 60 g of zinc acetate will be housed in the porcelain element dish, and it is put into the muffle furnace;

[0039] (2) Raise the temperature to 350 °C at a heating rate of 1 °C, and calcined at this temperature for 3 h, cooled to room temperature and ground to obtain a zinc oxide nanostructured visible photocatalytic material;

[0040] (3) Weigh 0.5 g of the zinc oxide nanostructure obtained in the above step (2), 500 g of light calcium carbonate, zirconia balls and 100 mL of deionized water into a ball mill jar, and then place it in a ball mill and mill it for 900 min ;

[0041] (4) Sieve the mixed solution obtained in the above step (3), let it settle, and wash to obtain the precipitated substance, and then blow the precipitated dry by blowing air, and finally obtain a light calcium carbonate composite powder with visible light catalytic activity.

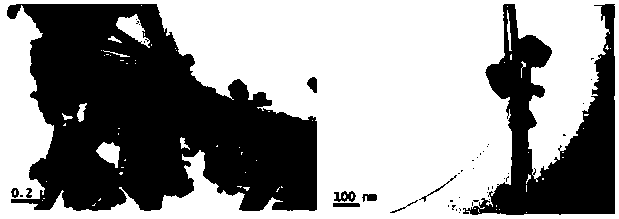

[0042] figure 1XRD figure for the obtained light calcium carbonate composite powder. It can be concluded from the...

Embodiment 2

[0044] (1) 20 g of zinc carbonate will be housed in the porcelain element dish, and it is put into the muffle furnace;

[0045] (2) Raise the temperature to 250 °C at a heating rate of 5 °C, and calcined at this temperature for 2 h, cooled to room temperature and ground to obtain a zinc oxide nanostructured visible photocatalytic material;

[0046] (3) Weigh 5 g of zinc oxide nanostructures obtained in the above step (2), 200 g of heavy calcium carbonate and 100 g of light calcium carbonate, zirconia balls and 50 mL of deionized water into a ball mill jar, and then put them Placed in a ball mill for 300 min;

[0047] (4) Sieve the mixed solution obtained in the above step (3), let it settle, and wash to obtain the precipitated substance, and then blow the precipitated dry by blowing air, and finally obtain a mixed calcium carbonate composite powder with visible light catalytic activity.

[0048] figure 2 The SEM image and XRD pattern of the obtained zinc oxide and mixed cal...

Embodiment 3

[0050] (1) 30 g of zinc oxalate is housed in a porcelain element dish, and it is put into a muffle furnace;

[0051] (2) Raise the temperature to 350 °C at a heating rate of 3 °C, and calcined at this temperature for 3 h, cooled to room temperature and ground to obtain a zinc oxide nanostructured visible photocatalytic material;

[0052] (3) Weigh 4 g of the zinc oxide nanostructure obtained in the above step (2), 400 g of ground calcium carbonate, zirconia balls and 80 mL of deionized water into a ball mill jar, and then place it in a ball mill for ball milling for 800 min;

[0053] (4) The mixed solution obtained in the above step (3) is sieved, left to settle, and washed to obtain the precipitated substance, and then the precipitate is dried by blowing air, and finally a heavy calcium carbonate composite powder with visible light catalytic activity is obtained.

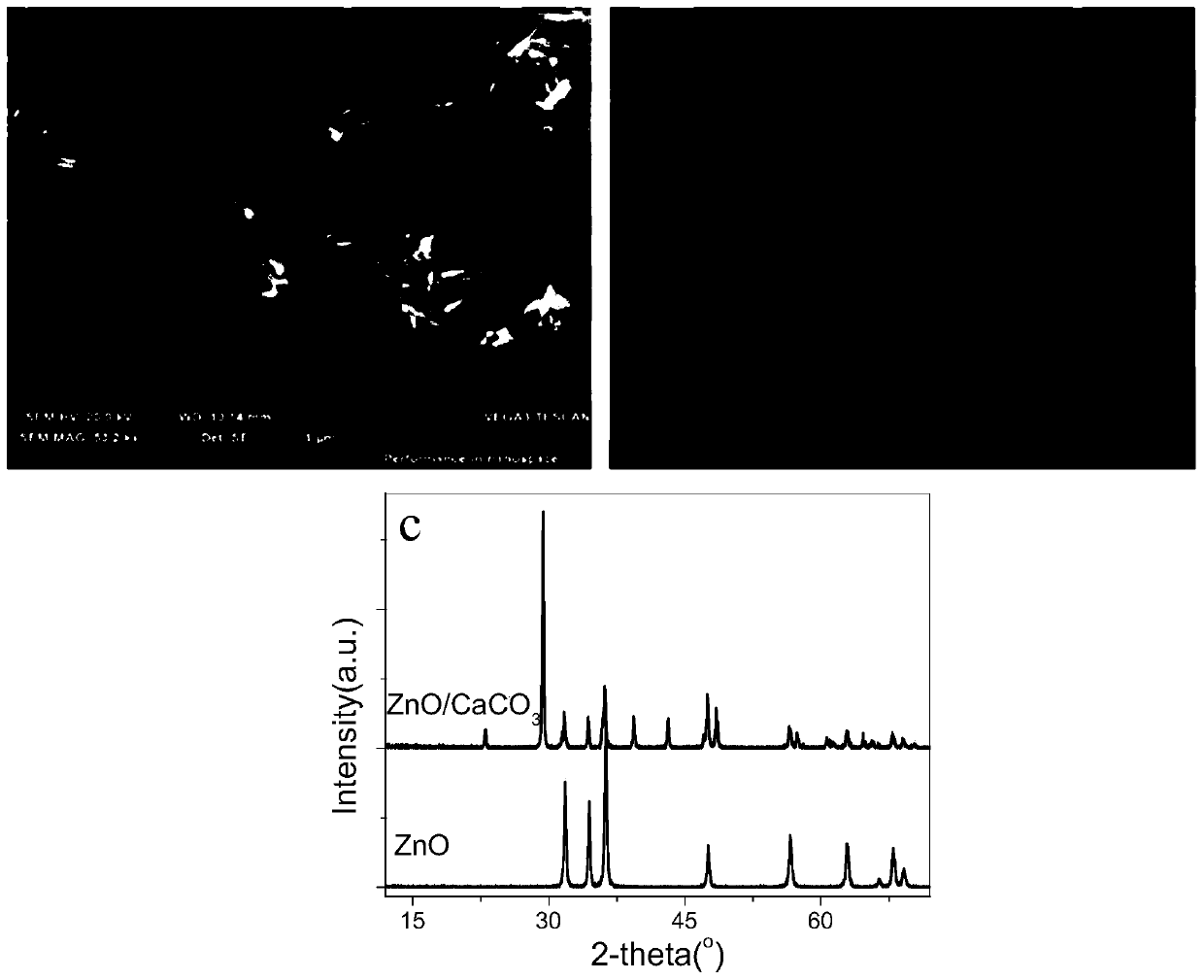

[0054] image 3 is a TEM image of the obtained ground calcium carbonate composite powder. It can be observed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com