Composite high-stability lubricant and preparation process thereof

A technology with high stability and preparation technology, applied in lubricating compositions, petroleum industry, etc., can solve the problem of insufficient anti-oxidation performance, anti-emulsification performance and resistance to shear deformation, which affects the stability and reliability of mechanical equipment operation, increases mechanical Equipment operation and maintenance costs and other issues, to achieve the effect of convenient acquisition, low cost of raw materials, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

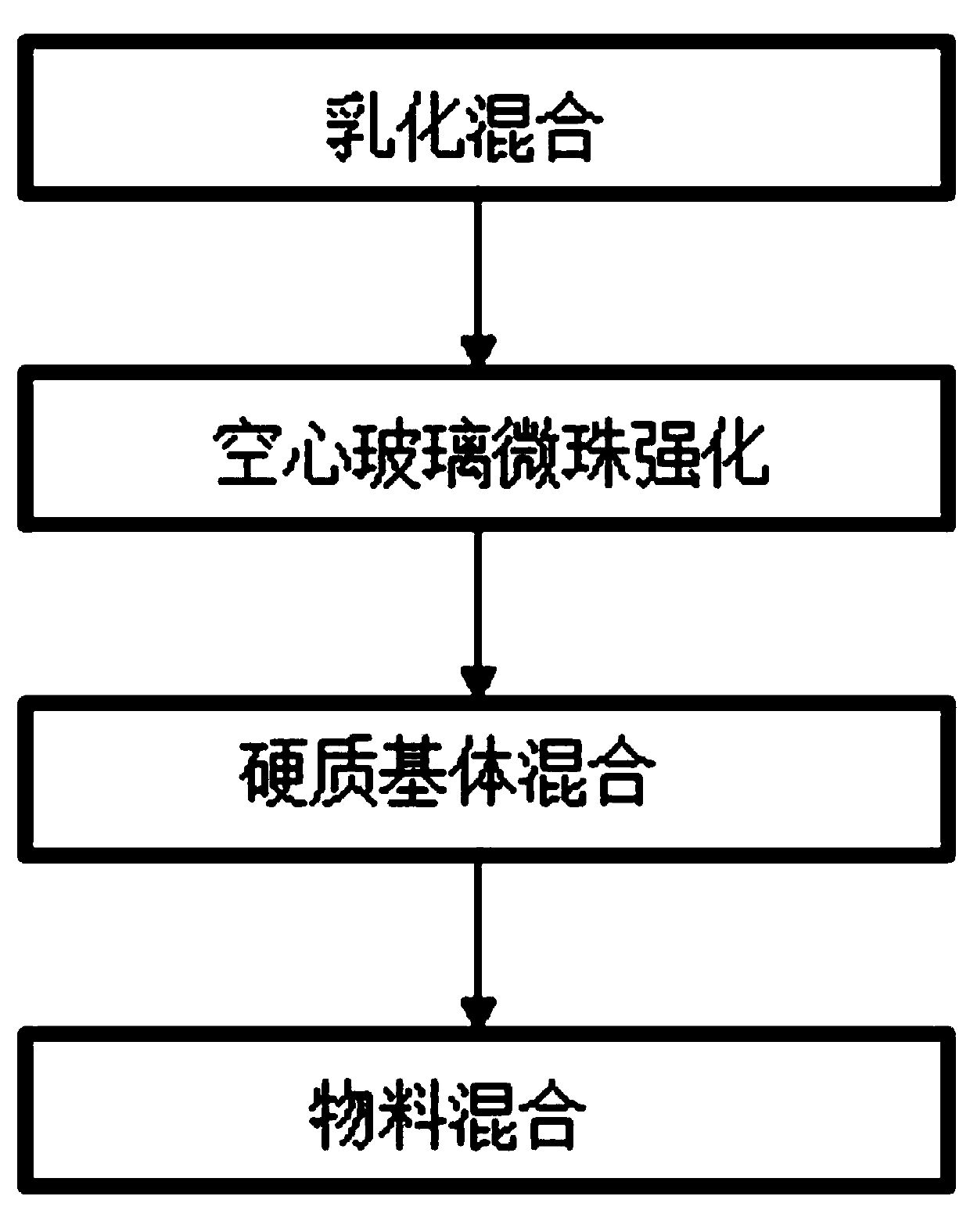

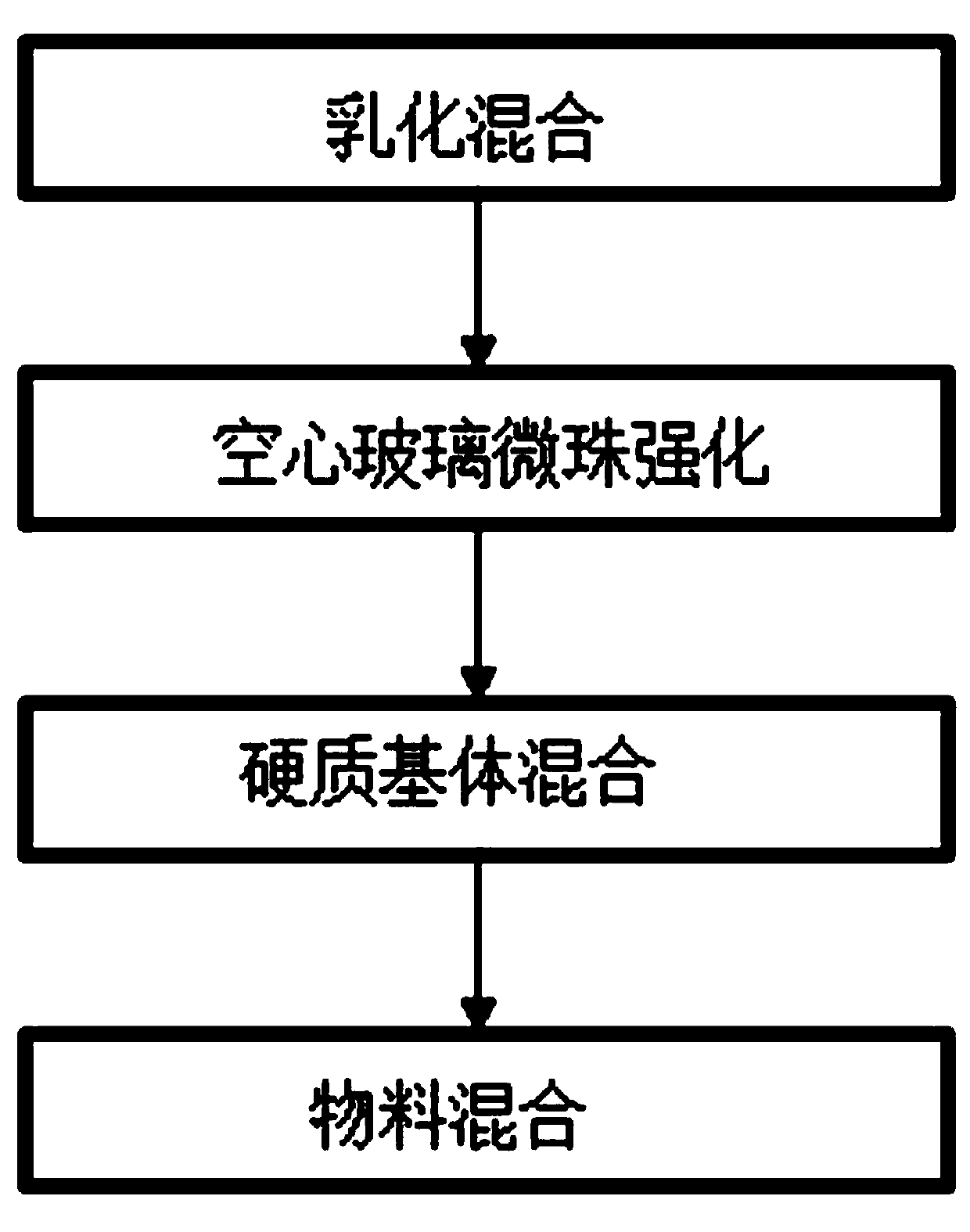

[0024] Such as figure 1 As shown, a composite high-stability lubricant is composed of the following mass percentage substances: metal oxide powder 5%, hollow glass microspheres 7%, oleic acid 7%, light rare earth 3%, ethyl silicate 5%, Water-based polyurea 1.5%, graphene fiber 0.5%, defoamer 0.1%, extreme pressure agent 1%, coupling agent 1.2%, toughening agent 1.8%, lubricant 0.5%, grease 2%, the balance is white Oil.

[0025] Wherein, the metal oxide powder is a mixture of alumina, titanium dioxide, magnesium oxide, manganese oxide, and tungsten oxide in any proportion, and the metal oxide powder, hollow glass microspheres and light rare earth are all 80-mesh solid powder structures .

[0026] In addition, the ethyl silicate and epoxy resin are all solid particle structures with a diameter of 0.01 mm, the water-based polyurea is pure water-based polyurea, and the graphene fiber has a diameter of 5 microns and a length of 0.1 mm , the defoamer is a silicon defoamer; the ex...

Embodiment 2

[0035] Such as figure 1As shown, a composite high-stability lubricant is composed of the following mass percentage substances: metal oxide powder 18%, hollow glass microspheres 23%, oleic acid 11%, light rare earth 5%, ethyl silicate 12%, Water-based polyurea 2.8%, graphene fiber 1.8%, defoamer 0.5%, extreme pressure agent 2.5%, coupling agent 2.1%, toughening agent 5.3%, lubricant 1.7%, grease 11%, and the balance is white Oil.

[0036] Wherein, the metal oxide powder is a mixture of alumina, sodium oxide, ferric oxide, boron oxide, and tungsten oxide at a ratio of 1:1, and the metal oxide powder, hollow glass microspheres and light rare earth are all 500 mesh Solid powder structure, the ethyl silicate and epoxy resin are all solid particle structures with a diameter of 0.1 mm.

[0037] In addition, the water-based polyurea is a semi-aqueous polyurea, the graphene fiber has a diameter of 10 microns and a length of 1 mm, and the defoamer is a silicon defoamer; the extreme pr...

Embodiment 3

[0046] Such as figure 1 As shown, a composite high-stability lubricant is composed of the following mass percentage substances: 9% metal oxide powder, 11% hollow glass microspheres, 9% oleic acid, 4% light rare earth, 9% ethyl silicate, Water-based polyurea 2%, graphene fiber 1%, defoamer 0.3%, extreme pressure agent 1.5%, coupling agent 1.7%, toughening agent 3.2%, lubricant 1.1%, grease 8%, and the balance is white Oil.

[0047] Wherein, the metal oxide powder is aluminum oxide, titanium dioxide, calcium oxide, manganese oxide, and tungsten oxide mixed in a ratio of 1:0.5:1.1:2.

[0048] In addition, the metal oxide powder, hollow glass microspheres and light rare earth are all solid powder structures of 80-500 mesh, and the ethyl silicate and epoxy resin are all solid particle structures with a diameter of 0.01-0.1 mm. The above-mentioned graphene fiber has a diameter of 5-10 microns and a length of no more than 1 mm.

[0049] At the same time, the water-based polyurea i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com