Preparation of hollow Mg/MnO2 super energetic materials

A hollow and maltose technology, applied in metal material coating process, electrolytic coating, vacuum evaporation coating and other directions, can solve the problems of difficult operation, complicated process, difficult realization of industrial application, etc., and achieves low cost, simple preparation, overcoming The effect of long mass transfer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

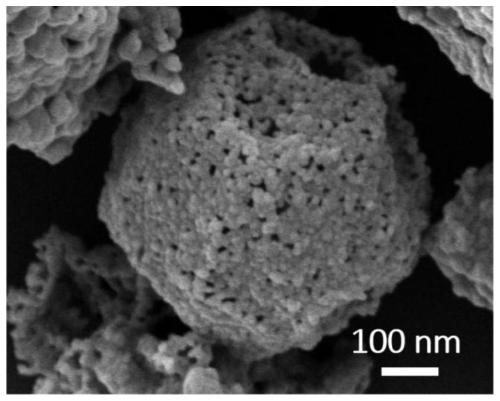

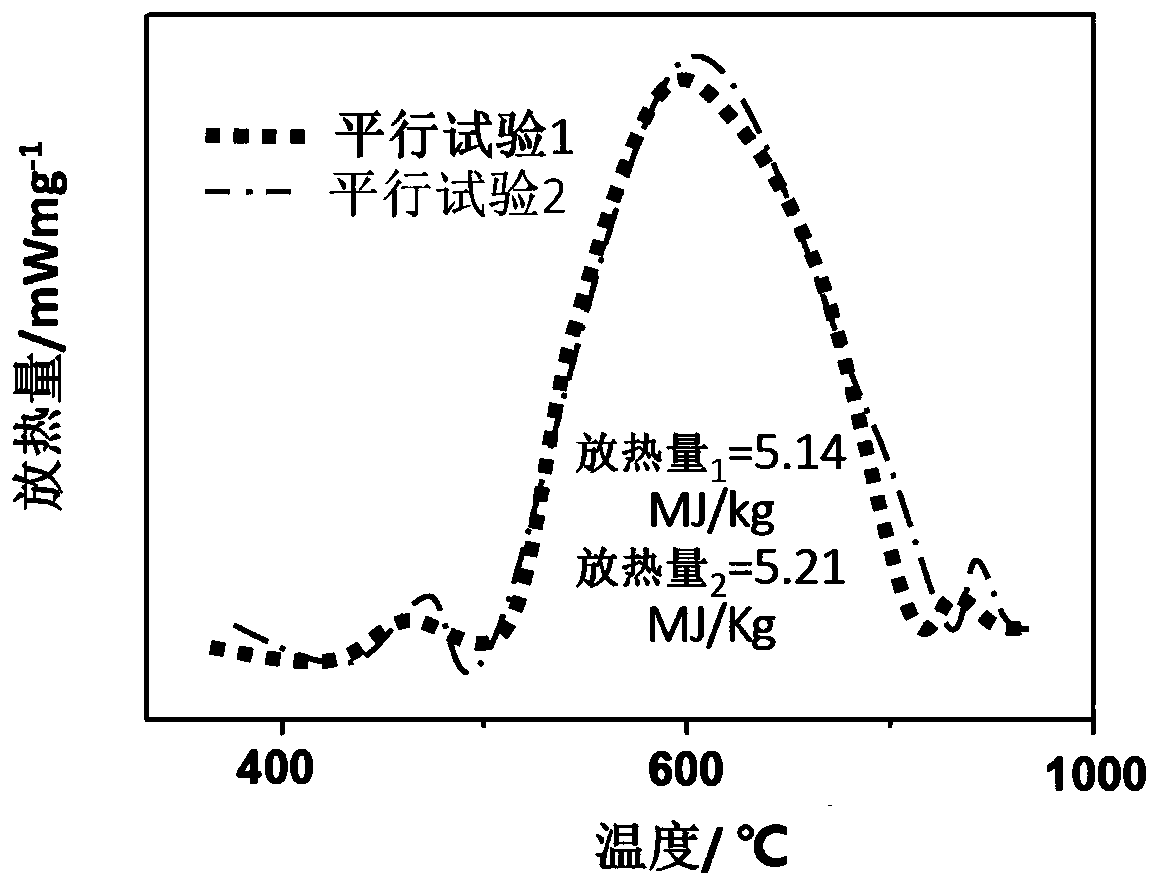

[0030] Precisely configure 0.1mol / L manganese nitrate solution in a 100mL Erlenmeyer flask, add a small amount of maltose, wherein the molar ratio of manganese nitrate to maltose is 1:10 -2 , and then continue to stir until all the maltose is dissolved in the Erlenmeyer flask, and then transfer the mixture to a 100mL reaction kettle. The heating rate was 20°C / min, and the reaction temperature and reaction time were controlled at 200°C and 8h, respectively. After the reaction was completed, it was naturally cooled to room temperature. Then carry out repeated centrifugal drying, the rotation speed is controlled at 1000r / min, and then placed in a vacuum drying oven at 25°C for 8 hours. Accurately weigh 2 mg of the obtained powder and disperse it in a volume ratio of 1:2:10 -2 Add 100mL of the dispersion liquid of glycerol, acetylacetone and chlorosulfonated polyethylene, and place it in an ultrasonic instrument for ultrasonic dispersion treatment for 30min. Insert the positive...

Embodiment 2

[0033] Others are the same as in Example 1, the voltage drop of the electrophoretic assembly is half of that of Example 1, the assembly efficiency, that is, the deposited mass per unit time is approximately halved, but the energy output capacity is sharply reduced by nearly 40%. The corresponding DSC heat release curve fits that the heat release under this condition is about 3.2MJ Kg -1 . Furthermore, the measured adhesion ratings remained essentially unchanged.

Embodiment 3

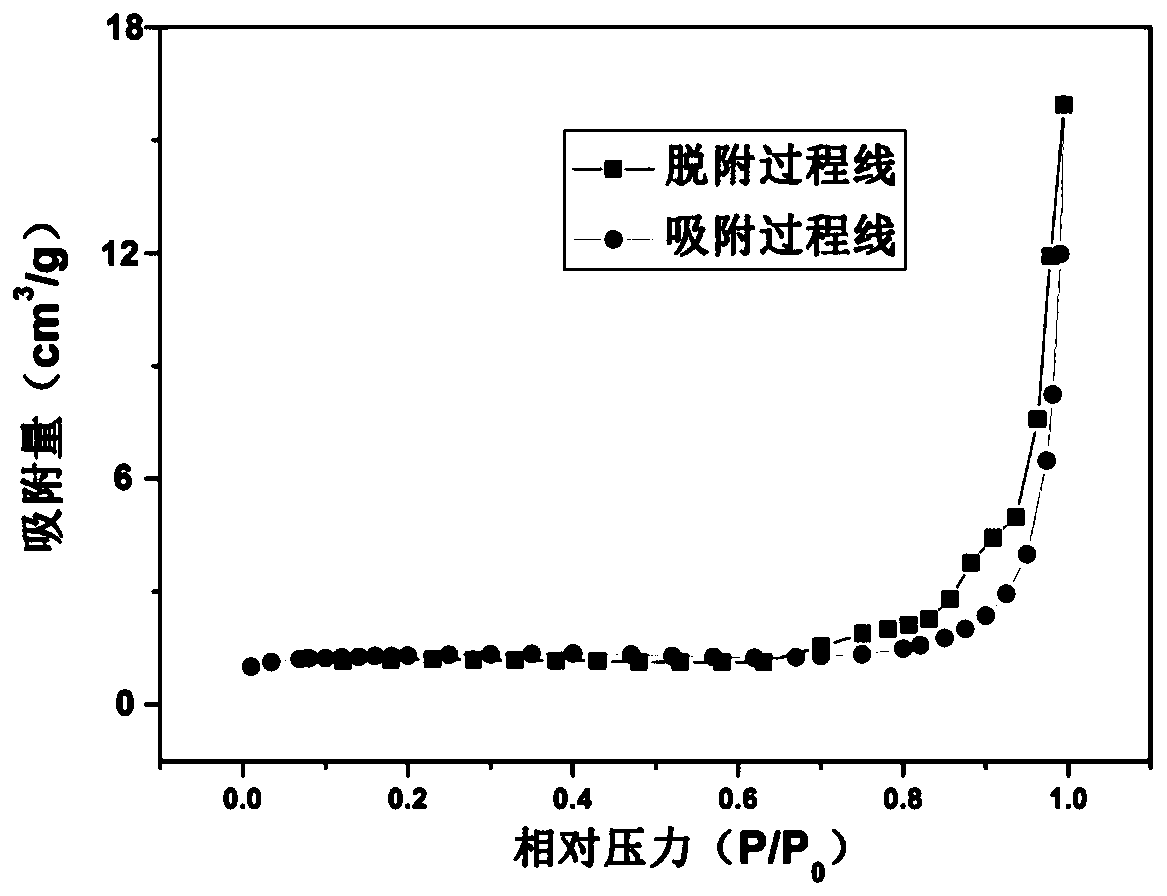

[0035] Other is the same as embodiment 1, and difference is that the concentration of manganese nitrate is 0.05mol / L, and other conditions are constant, MnO 2 The pores of the microspheres disappeared, and the specific surface area of the sample obtained under this condition was measured by a specific surface meter to be about 0.9m 2 / g, about 10% of the examples. Porous hollow Mg / MnO 2 The preparation of super thermites was not possible. Although an exothermic reaction can still occur, the corresponding exothermic heat at this time is about 30% of that of the example, which directly affects its synthesis efficiency and performance output.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Adhesion grade | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com