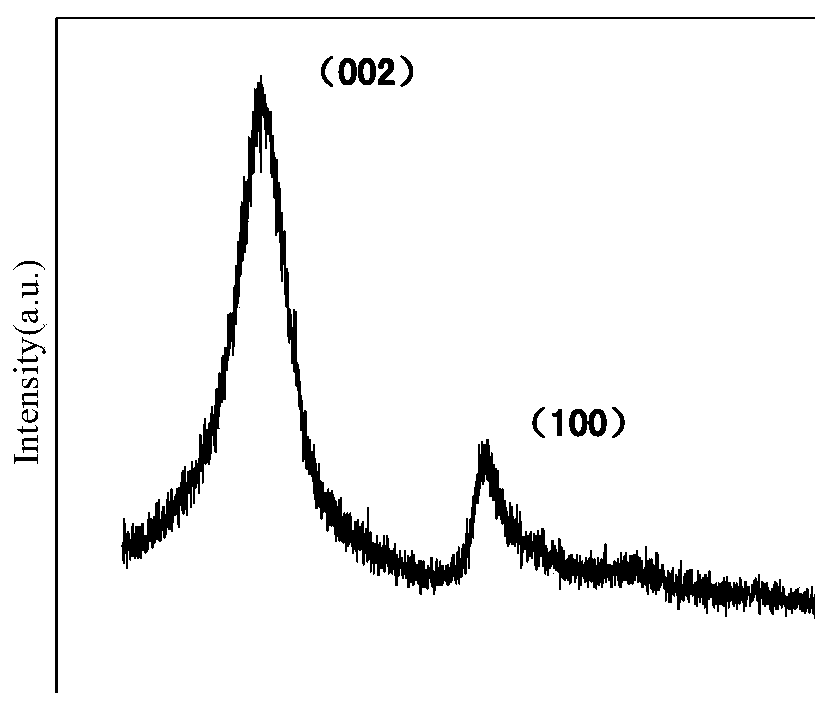

Preparing method and application of novel compound boron nitride adsorbing material

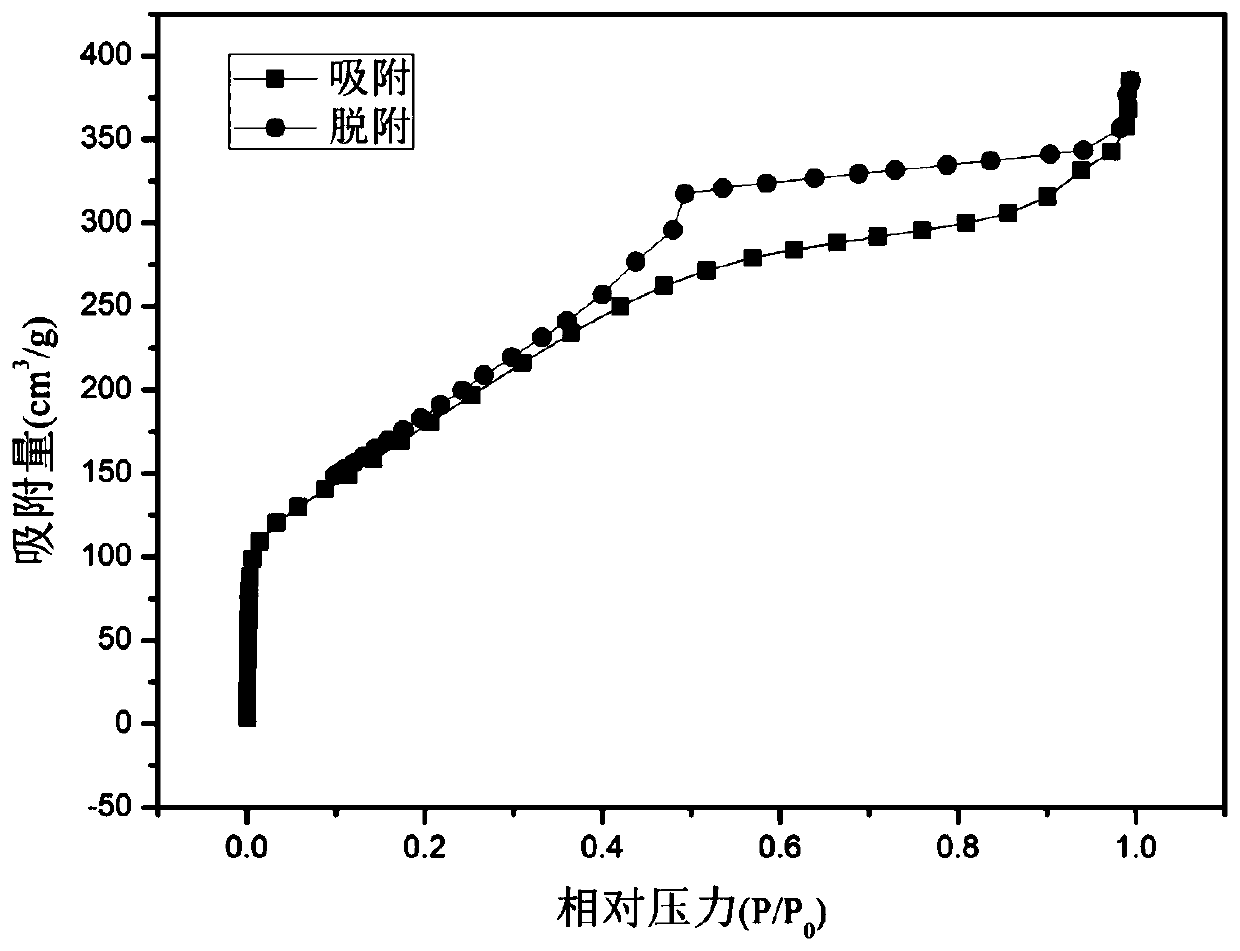

An adsorption material, boron nitride technology, which is applied in the synthesis field of new composite boron nitride adsorption materials, can solve the problems that cannot be used under high temperature and special extreme conditions, and achieve good chemical stability, simple method and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of novel composite boron nitride adsorption material:

[0037] (1) 0.1 gram of cetyl ethoxy sulfobetaine, 1.89 gram of melamine and 1.85 gram of boric acid are added to 100 ml of deionized water respectively, stirring makes boric acid and melamine evenly distributed in water, and it is placed in Heat to 85°C in a constant temperature shaking shaker, and keep shaking at this temperature to dissolve and keep warm for 4 hours;

[0038] (2) Slowly lower the temperature of the solution in step (1) to 25°C, a white flocculent precipitate precipitates, keep the temperature for 2 hours and then filter with suction to obtain a white solid precipitate, put it into an oven at 80°C drying in medium for 24 hours to obtain the precursor;

[0039] (3) Weighing 30wt% ammonium sulfate and adding it to the precursor obtained in step (2), using an agate mortar to grind and fully mix the two;

[0040] (4) Heat the solid powder obtained in step (3) in a nitrog...

Embodiment 2

[0047] The operating oscillation incubation time of step (1) in Example 1 was changed by 2 hours and 8 hours respectively, and other operations were all the same as in Example 1, and the product obtained was the same as in Example 1.

Embodiment 3

[0049] The operation of step (2) in Example 1 is lowered to temperature and changed to 20°C and 30°C respectively, and other operations are the same as in Example 1, and the product obtained is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com