Polyacrylonitrile/polyethyleneimine/graphene oxide nano porous sponge and preparation method thereof

A polyethylene imine and polyacrylonitrile technology, applied in chemical instruments and methods, water/sludge/sewage treatment, alkali metal oxides/hydroxides, etc., can solve problems such as brittleness, brittleness, and poor strength , to achieve the effect of excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

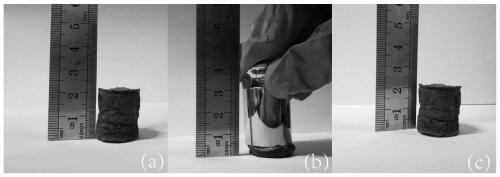

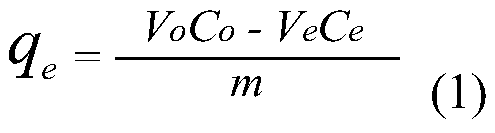

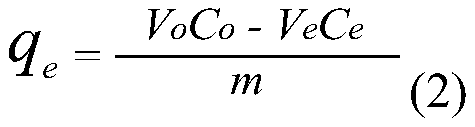

[0035] Add 10g of PAN to 90g of DMF, stir and dissolve at 50°C, cool to room temperature, add 10g of PEI, keep stirring at room temperature for 2 hours, then raise the temperature to 100°C within 0.5 hours, and then heat treatment for 0.5 hours, the polyethyleneimine Part of the amino group is connected with the cyano group on the polyacrylonitrile chain, and then cooled to room temperature to obtain a homogeneous and transparent polyacrylonitrile / polyethyleneimine solution; at 25 ° C, relative air humidity of 10%, and spinning voltage of 10 kV , continuous spinning for 2 hours to obtain a PAN / PEI bicomponent nanofiber membrane, which was dried for later use.

[0036] Weigh 10g of nanofiber membrane, cut the membrane into a square of about 0.5cm, put it into a beaker filled with 500g of distilled water and 5g of graphene oxide, start the high-speed homogeneous mixer with a dispersion speed of 8000rpm to disperse for 0.5h, and make the fiber membrane in water Form a uniform dis...

Embodiment 2-7

[0039] Add 10g of PAN to 90g of DMF, stir and dissolve at 50°C, cool to room temperature, add PEI with mass of 20g, 30g, 40g, 50g, 100g, 500g respectively, keep stirring at room temperature for 2 hours, and then raise the temperature to Heat at 100°C for another 0.5 hour to connect some of the amino groups of polyethyleneimine to the cyano groups on the polyacrylonitrile chain, and then cool to room temperature to obtain a homogeneous and transparent polyacrylonitrile / polyethyleneimine solution. Under the conditions of 25° C., relative air humidity of 10%, and spinning voltage of 10 kV, continuous spinning was performed for 2 hours to obtain a PAN / PEI bicomponent nanofiber membrane, which was dried for later use.

[0040] Prepare PAN / PEI / graphene oxide nanoporous sponge according to the method described in Example (1), and investigate the adsorption performance according to Example 1.

Embodiment 8-11

[0042] Prepare PAN / PEI two-component nanofiber membrane according to the method described in Example 5, and dry it for later use.

[0043] Weigh 10g of fiber film, cut the film into a square of about 0.5cm, put it into a beaker filled with 500g of distilled water and graphene oxide with a mass of 6g, 8g, 10g, and 12g, and start a high-speed homogeneous mixer to disperse for 0.5h, so that The fiber film forms a uniform dispersion in water, cools at minus 50°C for 1 hour, then puts it in a freeze dryer, and vacuum-dries it for 24 hours. After taking out the freeze-dried product, heat it at 120°C for 1 hour to obtain PAN / PEI / graphene oxide Nanoporous sponge.

[0044] According to the method described in Example 1, the adsorption performance of the porous sponge was investigated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com