Carrier, catalyst and preparation method for hydrodesulfurization

A hydrodesulfurization and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as single function and poor metal tolerance, and achieve Effects of increased deposition, high desulfurization capacity, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 500 grams of pseudoboehmite A1 (produced by Wenzhou Jingjing Alumina Co., Ltd., with a weight content of 70% on a dry basis) and roast at 460°C for 5.5 hours to prepare alumina.

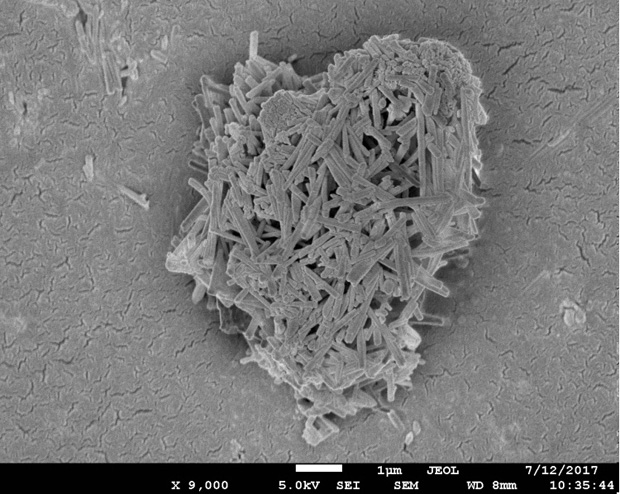

[0039] Weigh 50 grams of the above-mentioned alumina and place it in 200 grams of 18% ammonium bicarbonate aqueous solution, transfer the mixture into an autoclave, seal it, heat it at 120°C for 6 hours, and then dry the carrier at 115°C for 6 hours. The above-mentioned alumina was immersed in a polyethylene glycol-6000 solution with a mass concentration of 15% and soaked for 1.5 hours, and then the carrier was dried at 118°C for 6 hours to obtain rod-shaped alumina clusters.

[0040] Weigh 120 grams of pseudo-boehmite A1 (manufactured by Wenzhou Jingjing Alumina Co., Ltd., with a weight content of 70% on a dry basis), 10 grams of the above-mentioned rod-shaped alumina clusters, and 1.5 grams of scallop powder, and mix the above-mentioned materials evenly , adding an appropriate amount o...

Embodiment 2

[0043] Same as Example 1, except that the calcination temperature of pseudo-boehmite A1 is 540°C. The consumption of ammonium bicarbonate solution is 150 grams, and the mass concentration of solution is 15%. The heat treatment temperature is 145° C., and the treatment time is 8 hours. Polyethylene glycol-6000 was changed to polyethylene glycol-2000, and the mass concentration was 20%. The amount of rod-shaped alumina clusters added was 12 grams, and alumina carrier Z2 and hydrodesulfurization catalyst C2 were obtained. The properties of alumina carrier Z2 are shown in Table 1.

Embodiment 3

[0045] Same as Example 1, except that the roasting temperature of pseudo-boehmite is 510°C. The consumption of ammonium bicarbonate solution is 300 grams, and the mass concentration of solution is 10%. The heat treatment temperature was 110° C., and the treatment time was 8 hours. Polyethylene glycol-6000 was changed to polyethylene glycol-12000, and the mass concentration was 25%. The amount of rod-shaped alumina clusters added was 13 grams, and alumina carrier Z3 and hydrodesulfurization catalyst C3 were obtained. The properties of alumina carrier Z3 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com