Dry mixed gunite material

A shotcrete and dry-mixing technology, applied in the field of building materials, can solve the problems of physical health damage of on-site operators, poor cohesion of cement and concrete, and large environmental pollution, so as to reduce workers' pneumoconiosis, improve anti-stripping performance, and reduce dust pollution. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

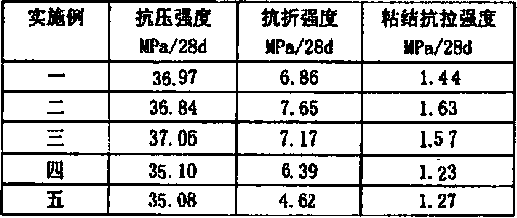

Embodiment 1

[0024] Portland cement 100 parts; quartz sand 120 parts; polymer dry milk 4 parts; polypropylene fiber 0.6 parts; early strength agent 0.3 parts; hydroxypropyl methylcellulose 0.2 parts; heavy calcium carbonate 25 parts; naphthalene series 0.5 parts of water reducer; 0.3 parts of cellulose ether; add to twin-screw high-efficiency mixer, fully stir for 20 minutes, mix well, put into mortar mixer, and then add to water with 20 parts of air-entraining agent , mixed and stirred into wet mortar, and then sprayed with a wet shotcrete machine, and the construction thickness is 12mm.

Embodiment 2

[0026] Portland cement 100 parts; quartz sand 250 parts; polymer dry emulsion 5 parts; polypropylene fiber 0.7 parts; early strength agent 0.4 parts; hydroxypropyl methylcellulose 0.2 parts; heavy calcium carbonate 10 parts; naphthalene 0.6 parts of water reducer; 0.2 parts of cellulose ether; add to twin-screw high-efficiency mixer, fully stir for 25 minutes, mix well, put into mortar mixer, and then add to water with 30 parts of air-entraining agent , mixed and stirred into wet mortar, and then sprayed with a wet shotcrete machine, and the construction thickness is 15mm.

Embodiment 3

[0028] Portland cement 100 parts; quartz sand 200 parts; polymer dry emulsion 3 parts; polypropylene fiber 0.5 parts; early strength agent 0.2 parts; hydroxypropyl methylcellulose 0.3 parts; heavy calcium carbonate 30 parts; naphthalene series 0.4 parts of water reducer; 0.4 parts of cellulose ether; add to the twin-screw high-efficiency mixer, fully stir for 30 minutes, mix well, put it into the mortar mixer, and then add it to the water with 10 parts of air-entraining agent , mixed and stirred into wet mortar, and then sprayed with a wet shotcrete machine, and the construction thickness is 12mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com