Antibacterial flame-retardant needle-punched compound nonwoven fabric preparation method

A needle-punched composite and non-woven fabric technology, applied in the field of flame-retardant materials, can solve the problems of lack of antibacterial effect, etc., and achieve good promotion and application value, high strength, and good flame-retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

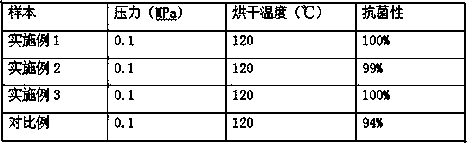

Examples

Embodiment 1

[0026] The composite non-woven fabric is composed of an antibacterial layer, a flame-retardant layer, and a needle-punched non-woven fabric layer, wherein the flame-retardant layer is prepared by the following method:

[0027] A. With 10 parts of urea, 5 parts of melamine, 30 parts of formaldehyde and 60 parts of deionized water, add 5 parts of triethanolamine to obtain a preliminary solution;

[0028] B. Mix 15 parts of ammonium phosphate, 70 parts of deionized water, and 0.1 part of Tween-80 surfactant evenly, then stir on a homogeneous mixer at a high speed of about 1000 rpm, emulsify and disperse for 10 minutes, then add 30 parts of distilled water, Adjust the speed to about 2000rpm, homogenize and disperse for 20 minutes to obtain a stable emulsion, then add 0.1 part of maleic anhydride graft compatibilizer, 0.1 part of Tween-80 surfactant, adjust the pH value to 6 with tartaric acid solution, add dropwise One-fifth of the preparatory solution was obtained in step A. Afte...

Embodiment 2

[0044] The composite non-woven fabric is formed from an antibacterial layer, a flame-retardant layer, and a needle-punched non-woven fabric layer, wherein the flame-retardant layer is prepared by the following method:

[0045] A. With 11 parts of urea, 6 parts of melamine, 28 parts of formaldehyde and 55 parts of deionized water, add 3 parts of triethanolamine to obtain a preliminary solution;

[0046] B. Mix 14 parts of ammonium phosphate, 13 parts of ammonium phosphate, 75 parts of deionized water, and 0.1 part of Tween-80 surfactant evenly, then stir on a homogeneous mixer at a high speed of about 1000 rpm, and emulsify and disperse for 10 minutes. Then add 23 parts of distilled water, adjust the speed to about 2000rpm, homogenize and disperse for 20 minutes to obtain a stable emulsion, then add 0.1 part of maleic anhydride graft compatibilizer, 0.1 part of Tween-80 surfactant, adjust the pH with tartaric acid solution value to 6, drop one-fifth of the preparation solution ...

Embodiment 3

[0063] The composite non-woven fabric is composed of an antibacterial layer, a flame-retardant layer, and a needle-punched non-woven fabric layer, wherein the flame-retardant layer is prepared by the following method:

[0064] A. With 12 parts of urea, 7 parts of melamine, 25 parts of formaldehyde and 50 parts of deionized water, add 1 part of triethanolamine to obtain a preliminary solution;

[0065] B. Mix 10 parts of ammonium phosphate, 80 parts of deionized water, and 0.1 part of Tween-80 surfactant evenly, then stir on a homogeneous mixer at a high speed of about 1000 rpm, emulsify and disperse for 10 minutes, then add 15 parts of distilled water, Adjust the speed to about 2000rpm, homogenize and disperse for 20 minutes to obtain a stable emulsion, then add 0.2 parts of maleic anhydride graft compatibilizer, 0.1 part of Tween-80 surfactant, adjust the pH value to 6 with tartaric acid solution, add dropwise One-fifth of the preparatory solution was obtained in step A. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Damage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com