Preparation method of biomass carbon material for solar evaporated water and application of biomass carbon material

A technology of biomass carbon and solar energy, applied in solar thermal power generation, carbon preparation/purification, solar thermal energy, etc., can solve the problem of incompatibility between light-to-heat conversion efficiency and cost-effectiveness, so as to improve the utilization rate of solar energy and accelerate the evaporation rate , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

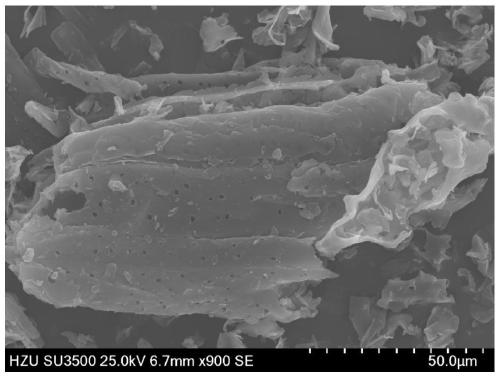

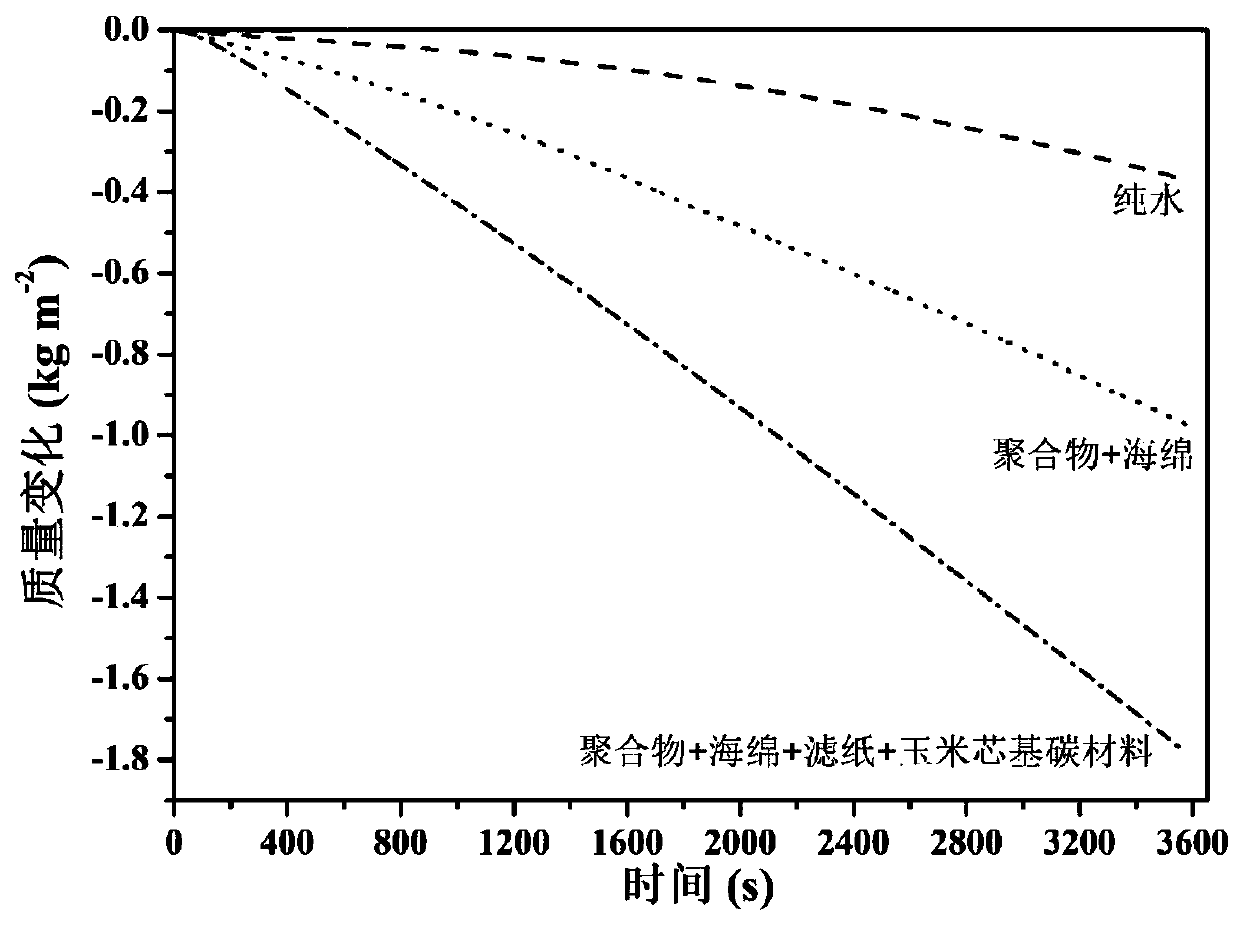

[0026] (1) Wash the corncobs with distilled water to remove impurities, dry, pulverize, and sieve, put them into a porcelain boat and put them in a tube furnace. 2 Atmosphere, at 5°C min -1 The heating rate was increased to 750°C, and the temperature was kept at room temperature for 2 hours. After drying, the corncob-based carbon material was obtained (the SEM image of the material is shown in figure 2 ).

[0027] (2) After grinding 20 mg of corncob-based carbon material for half an hour, disperse it in distilled water, and ultrasonically disperse it for 30 minutes to obtain a corncob-based carbon suspension. The corncob-based carbon material suspension was placed on a circular filter paper with a diameter of 4 cm for vacuum filtration, and dried at 60°C for 2 hours to obtain a filter paper loaded with corncob-based carbon materials. The bent filter paper did not scatter powder.

[0028] (3) a cylindrical sponge with a diameter of 3 cm and a thickness of 2 cm is placed in t...

Embodiment 2

[0036] (1) Remove the skin of the corn stalk, remove the joint, and cut it into a length of 3-4cm. After drying to remove moisture, put it into a porcelain boat and put it in a tube furnace. 2 Atmosphere, at 5°C min -1 The heating rate was increased to 800°C, and the temperature was kept for 2 hours to reach room temperature. After drying, the corn stalk-based carbon material was obtained and ground into powder.

[0037](2) Take 8 mg of corn stalk carbon material, disperse it in distilled water, and ultrasonically disperse it for 30 min to obtain a corn stalk-based carbon suspension. The carbon material suspension was vacuum-filtered on a circular filter paper with a diameter of 4 cm, and dried at 60° C. for 2 hours to obtain a filter paper loaded with corn stalk-based carbon materials.

[0038] (3) a cylindrical sponge with a diameter of 3 cm and a thickness of 2 cm is placed in the middle of a polystyrene circular foam ring with a thickness of 0.5 cm and a height of 2 cm, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com