Energy-saving and environment-friendly building material and preparation method thereof

A technology for building materials, energy saving and environmental protection, applied in the field of building materials, can solve the problems of excessive exploitation of natural aggregates, high cost, environmental damage, etc., and achieve the effects of reducing production costs, excellent thermal insulation effect, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An energy-saving and environment-friendly building material, which is made of the following components in parts by weight: 30 parts of ordinary Portland cement with a strength of 42.5, 15 parts of residual sludge from a sewage treatment plant with a moisture content of 30%, and 70 parts of limestone gravel 40 parts of steel slag powder with a fineness modulus of 2.56, 15 parts of sycamore wadding, 4 parts of tannic acid, 0.5 parts of ferric chloride, 0.5 parts of sodium hexametaphosphate, 1 part of polyacrylamide, and 0.5 parts of polyvinylpyrrolidone , 1 part of RSD-8 superplasticizer, 60 parts of water.

[0035] Specifically follow the steps below:

[0036] Step 1: Take 30 parts of ordinary Portland cement with a strength of 42.5, 15 parts of residual sludge from a sewage treatment plant with a water content of 30%, 70 parts of limestone gravel, and steel slag with a fineness modulus of 2.56 according to parts by weight 40 parts of powder, 15 parts of sycamore waddin...

Embodiment 2

[0046] An energy-saving and environment-friendly building material, which is made of the following components in parts by weight: 20 parts of ordinary Portland cement with a strength of 42.5, 20 parts of residual sludge from a sewage treatment plant with a moisture content of 30%, and 60 parts of limestone gravel 50 parts of steel slag powder with a fineness modulus of 2.56, 10 parts of sycamore wadding, 5 parts of tannic acid, 0.5 parts of ferric chloride, 1 part of sodium hexametaphosphate, 0.6 parts of polyacrylamide, and 1 part of polyvinylpyrrolidone , RSD-8 type superplasticizer 0.5 parts, water 50 parts.

[0047] The specific preparation method is the same as in Example 1, except that the formula in Example 1 is replaced with that of Example 2. It should be noted that in step 3 of the preparation method, quicklime is added to adjust the pH of the system to 8.2.

Embodiment 3

[0049] An energy-saving and environment-friendly building material, which is made of the following components in parts by weight: 40 parts of ordinary Portland cement with a strength of 42.5, 10 parts of residual sludge from a sewage treatment plant with a moisture content of 30%, and 80 parts of limestone gravel 40 parts of steel slag powder with a fineness modulus of 2.56, 20 parts of sycamore wadding, 3 parts of tannic acid, 0.8 parts of ferric chloride, 0.8 parts of sodium hexametaphosphate, 0.5 parts of polyacrylamide, and 0.8 parts of polyvinylpyrrolidone , RSD-8 type superplasticizer 0.8 parts, water 80 parts.

[0050] The specific preparation method is the same as in Example 1, except that the formula in Example 1 is replaced with that of Example 3. It should be noted that in step 3 of the preparation method, quicklime is added to adjust the pH of the system to 9.

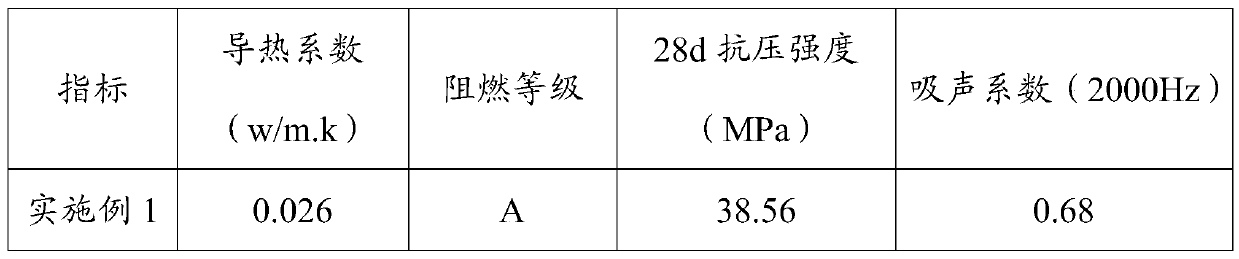

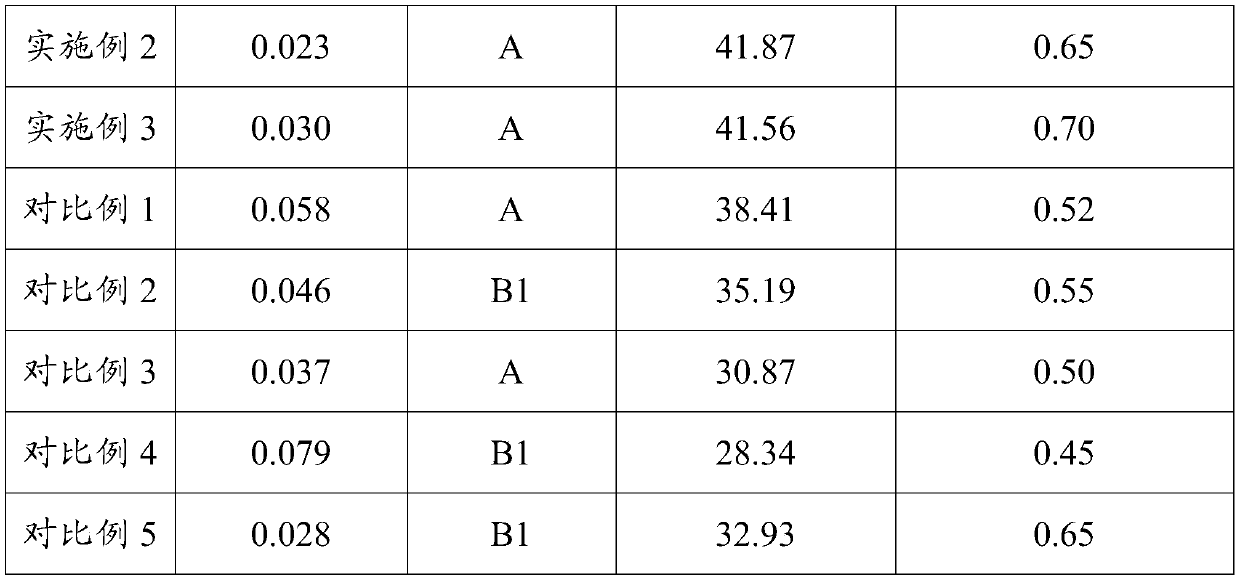

[0051] In order to further illustrate the effects of the present invention, the present invention also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com