Super-hydrophobic antifogging masterbatches for film and preparation of super-hydrophobic antifogging masterbatches

A super-hydrophobic and anti-fog technology, which is applied in the field of super-hydrophobic anti-fog masterbatch, can solve the problems of anti-fog effect related to small molecule migration, affecting anti-fog effect, and weakening anti-fog effect, so as to avoid adhesion and polymerization, Unique conformational flexibility and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method of superhydrophobic anti-fog master batch for thin film, mainly comprises the following steps:

[0041] The first step: melt grafting to prepare grafted polypropylene PP-g-GMA:

[0042] With polypropylene (PP) as the carrier, glycidyl methacrylate (GMA) as the grafting monomer, dicumyl peroxide (DCP) as the initiator, PP, DCP and GMA are blended and enter from the feeding port Extruder melt extrusion. During the extrusion melting process, DCP forms small molecular free radicals at high temperature, attacks the tertiary carbon on the PP main chain, forms macromolecular free radicals, reacts with the double bond of GMA molecules, and forms grafted polypropylene PP-g- GMA, the prepared grafted polypropylene PP-g-GMA was pelletized and dried.

[0043] The chemical reaction scheme of GMA-grafted PP is shown below, where the long chain represents the PP molecular chain.

[0044]

[0045] PP:GMA:DCP ratio 100:10:1, PP:GMA:DCP ratio 100:10:1, ...

Embodiment 2

[0055] The performance test of the film prepared in Example 1 was performed with the superhydrophobic anti-fog masterbatch.

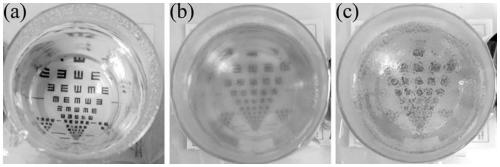

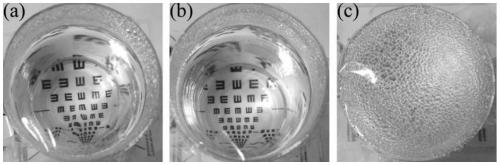

[0056] (1) Cold fog test anti-fog effect comparison

[0057] Add different anti-fog masterbatches to prepare anti-fog films. The anti-fog films are prepared by casting method. For BOPP anti-fog films with a film thickness of 28 μm, the thickness of the two surface layers is 2 μm, and the core layer is 24 μm. Hot fog and cold fog tests are carried out for comparison. Anti-fog effect.

[0058]

[0059] According to the national standard GB / T 31726-2015 "Plastic Film Anti-Fog Test Method", the anti-fog performance of the three types of films is tested, using 6.1 cold fog method and 6.3 water bath hot fog method to test its performance under cold, humid and hot conditions anti-fog performance.

[0060] According to the test method of cold fog method, pour 200mL of pure water into a flat beaker, fix the film with a rubber band, put it in a refrigerator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com