Method for improving sintering compactness of W-Y2O3 composite material

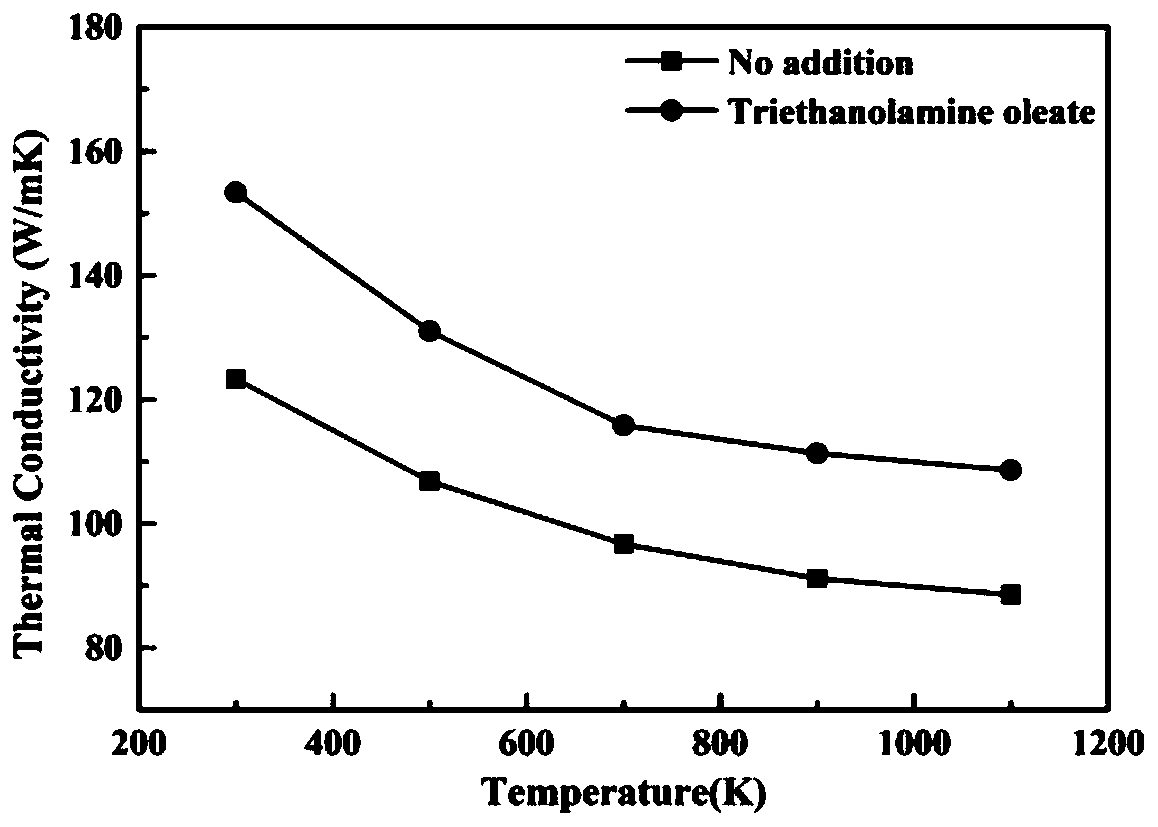

A technology of W-Y2O3 and composite materials, which is applied in the field of improving the sintering compactness of W-Y2O3 composite materials, can solve problems such as cracks, and achieve the effects of uniform powder particle size distribution, increasing relative density, and refining grain size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, improve W-Y 2 o 3 A method for sintering compactness of composite materials, comprising the steps of:

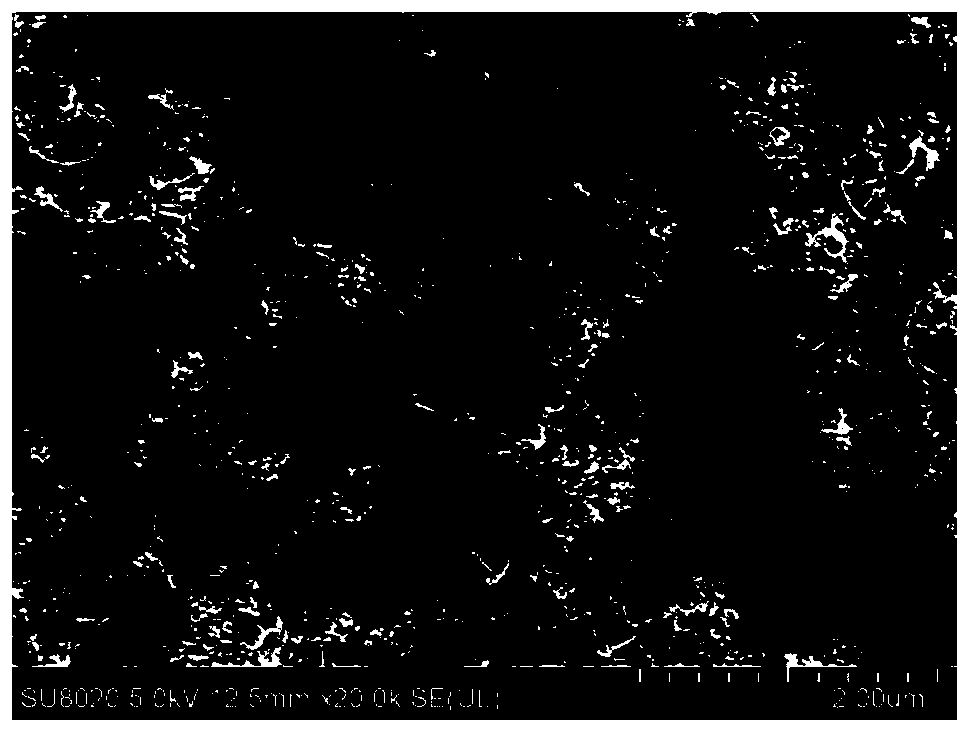

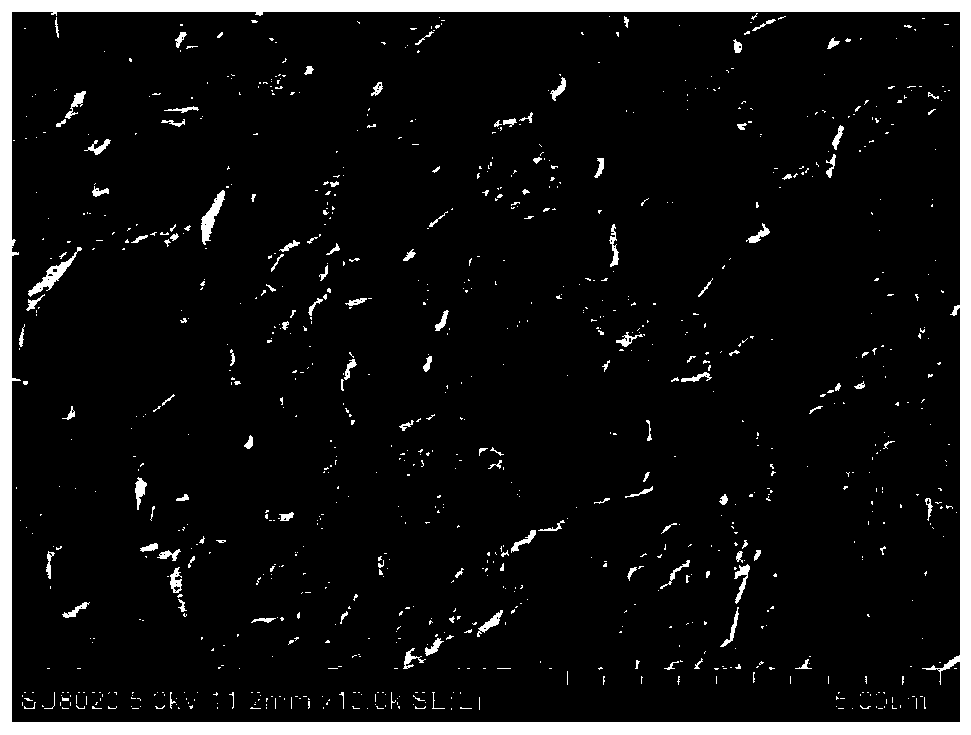

[0026] Step 1: Preparation of powder

[0027] Ammonium metatungstate (AMT, Aladdin, purity ≥ 99.95%), yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O, Aladdin, purity ≥ 99.5%) and surfactant triethanolamine oleate (C 16 h 22 N 4 o 3 , purity 99%) were respectively dissolved in a certain amount of deionized water, and then mixed uniformly. Oxalic acid (C 2 h 2 o 4 2H 2 O, analytically pure) was added as a precipitant into the mixed solution and stirred evenly, ultrasonically oscillated at 120°C and stirred continuously until the precursor was obtained, the dried and ground powder was put into a tube furnace for reduction, and the reducing atmosphere was hydrogen, and finally get w-y 2 o 3 Composite powder, powder particle size is 200nm.

[0028] The addition amounts of triethanolamine oleate, yttrium nitrate and oxalic acid are respectively 1%, ...

Embodiment 2

[0035] In this embodiment, improve W-Y 2 o 3 A method for sintering compactness of composite materials, comprising the steps of:

[0036] Step 1: Preparation of powder

[0037] Ammonium metatungstate (AMT, Aladdin, purity ≥ 99.95%), yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O, Aladdin, purity ≥ 99.5%) and surfactant triethanolamine oleate (C16 h 22 N 4 o 3 , purity 99%) were respectively dissolved in a certain amount of deionized water, and then mixed uniformly. Oxalic acid (C 2 h 2 o 4 2H 2 O, analytically pure) was added as a precipitating agent into the mixed solution and stirred evenly, ultrasonically oscillated at 130°C and stirred continuously until the precursor was obtained, the dried and ground powder was put into a tube furnace for reduction, and the reducing atmosphere was hydrogen, and finally get w-y 2 o 3 Composite powder, powder particle size is 300nm.

[0038] The addition amounts of triethanolamine oleate, yttrium nitrate and oxalic acid are respectivel...

Embodiment 3

[0045] In this embodiment, improve W-Y 2 o 3 A method for sintering compactness of composite materials, comprising the steps of:

[0046] Step 1: Preparation of powder

[0047] Ammonium metatungstate (AMT, Aladdin, purity ≥ 99.95%), yttrium nitrate (Y(NO 3 ) 3 ·6H 2 O, Aladdin, purity ≥ 99.5%) and surfactant triethanolamine oleate (C 16 h 22 N 4 o 3 , purity 99%) were respectively dissolved in a certain amount of deionized water, and then mixed uniformly. Oxalic acid (C 2 h 2 o 4 2H 2 O, analytically pure) was added into the mixed solution as a precipitant and stirred evenly, ultrasonically oscillated at 140°C and stirred continuously until the precursor was obtained, the dried and ground powder was put into a tube furnace for reduction, and the reducing atmosphere was hydrogen, and finally get w-y 2 o 3 Composite powder, powder particle size is 400nm.

[0048] The addition amounts of triethanolamine oleate, yttrium nitrate and oxalic acid are respectively 3%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com