Film-type composite solid electrolyte, preparation method thereof, and all-solid lithium battery

A solid electrolyte and thin-film technology, applied in the field of solid electrolyte materials for lithium batteries, to achieve the effects of high ionic conductivity, small contact resistance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

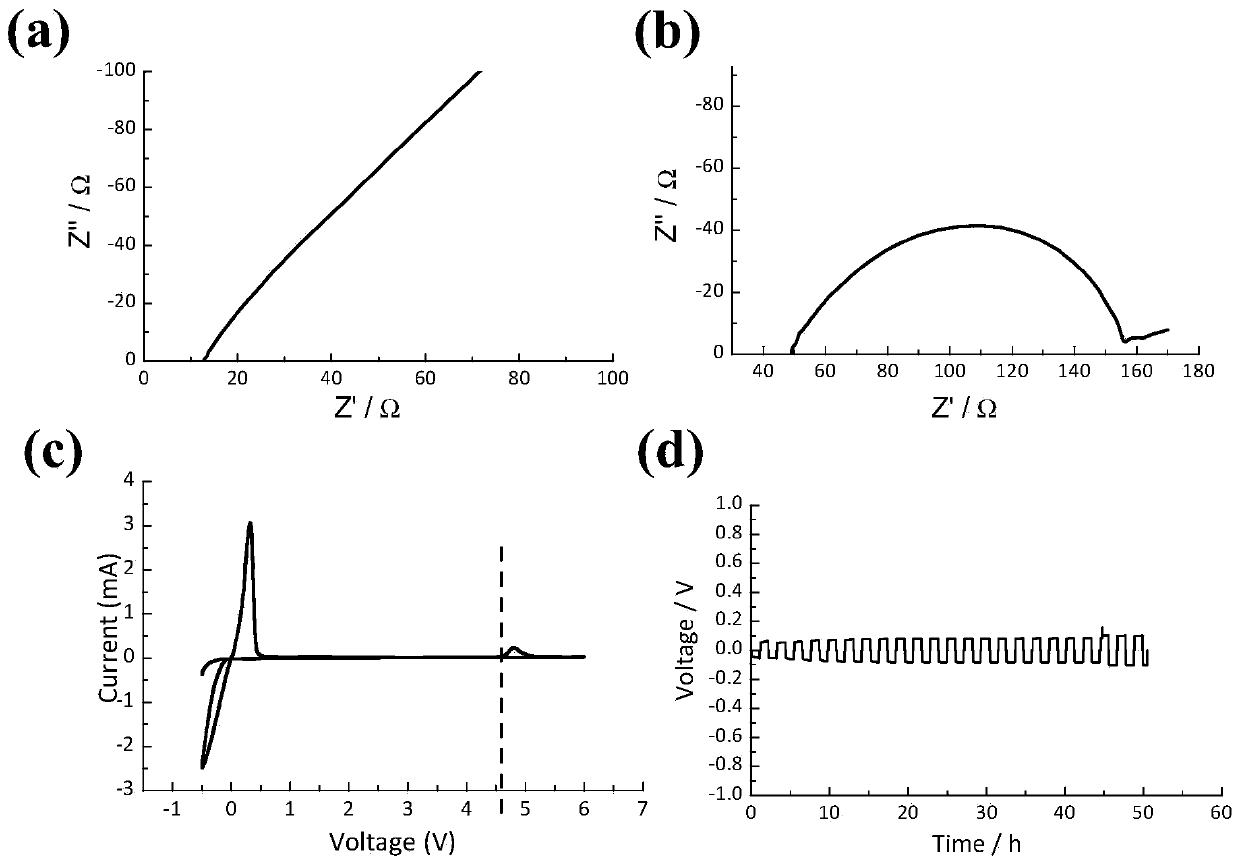

[0027] Lithium bistrifluoromethanesulfonimide was used as the lithium-conducting agent, polyethylene oxide was used as the polymer and binder, and tetraethylene glycol dimethyl ether was used as the plasticizer. Wherein the monomer molar ratio of bistrifluoromethylsulfonimide lithium and polyethylene oxide is 1:5, the mass ratio of bistrifluoromethylsulfonimide lithium-polyoxyethylene and tetraethylene glycol dimethyl ether 1:1. After weighing, it was dissolved in an acetonitrile solvent so that the concentration of polyethylene oxide was 5 wt%, and heated at 50° C. with magnetic stirring for 3 hours to obtain a uniform solution. Coat a layer of solution on the surface of the lithium-ion battery separator, scrape off the excess solution on the surface, then heat and dry in an oven at 70°C for 5 minutes, then do the same on the other side, and finally dry at 70°C for 1 hour. Test the impedance of the solid electrolyte and calculate the ionic conductivity; assemble into a lithi...

Embodiment 2

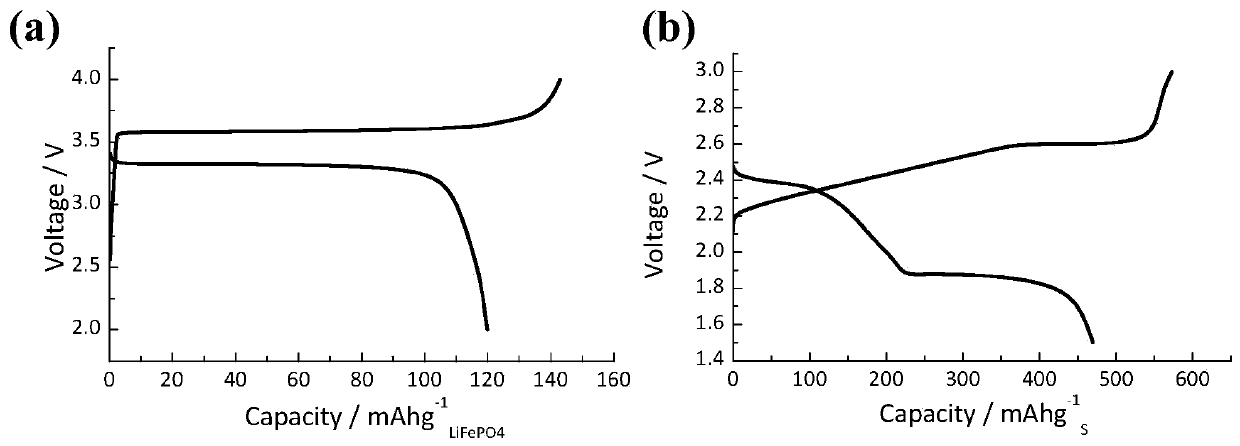

[0033] Lithium bistrifluoromethanesulfonyl imide is used as a lithium-conducting agent, polyethylene oxide is used as a polymer and a binder, and tetraethylene glycol dimethyl ether is used as a plasticizer. Wherein the monomer molar ratio of bistrifluoromethylsulfonimide lithium and polyethylene oxide is 1:5, the mass ratio of bistrifluoromethylsulfonimide lithium-polyoxyethylene and tetraethylene glycol dimethyl ether 1:1. After weighing, it was dissolved in an acetonitrile solvent so that the concentration of polyethylene oxide was 5 wt%, and heated at 50° C. with magnetic stirring for 3 hours to obtain a uniform solution. Coat a layer of solution on the surface of the lithium-ion battery separator, scrape off the excess solution on the surface, then heat and dry in an oven at 70°C for 5 minutes, then do the same on the other side, and finally dry at 70°C for 1 hour. Then pack into metal lithium / solid electrolyte / lithium iron phosphate button cell (CR2032), metal lithium / s...

Embodiment 3

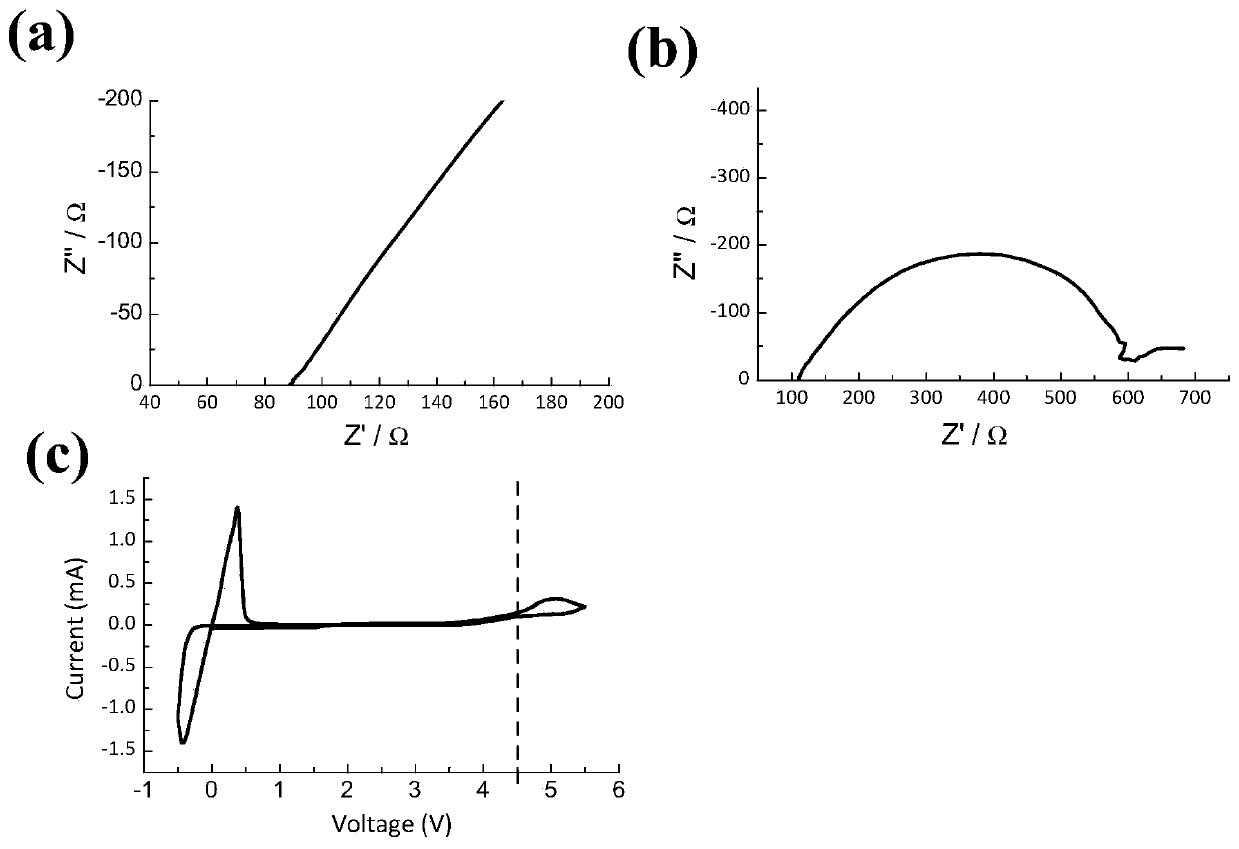

[0038] Lithium bistrifluoromethanesulfonyl imide is used as a lithium-conducting agent, polyethylene oxide is used as a polymer and a binder, and tetraethylene glycol dimethyl ether is used as a plasticizer. Wherein the monomer molar ratio of bistrifluoromethylsulfonimide lithium to polyethylene oxide is 1:30, and the mass ratio of bistrifluoromethylsulfonimide lithium-polyoxyethylene to tetraethylene glycol dimethyl ether 1:1. After weighing, it was dissolved in an acetonitrile solvent so that the concentration of polyethylene oxide was 5 wt%, and heated at 50° C. with magnetic stirring for 3 hours to obtain a uniform solution. Coat a layer of solution on the surface of the lithium-ion battery separator, scrape off the excess solution on the surface, then heat and dry in an oven at 70°C for 5 minutes, then do the same on the other side, and finally dry at 70°C for 1 hour. Use a self-made mold to test the impedance of the solid electrolyte and calculate the ionic conductivity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com