Graphite/titanium dioxide composite material based polyvinylidene fluoride electrocatalytic ultrafiltration membrane

A technology of polyvinylidene fluoride and composite materials, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, ultrafiltration, etc., can solve ultrafiltration membrane membrane fouling and organic pollutants are difficult to effectively Removal and other problems, to achieve the effect of high electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

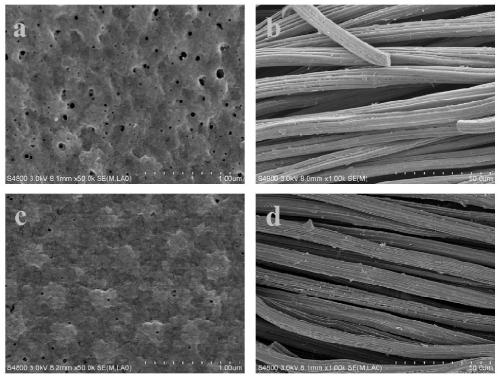

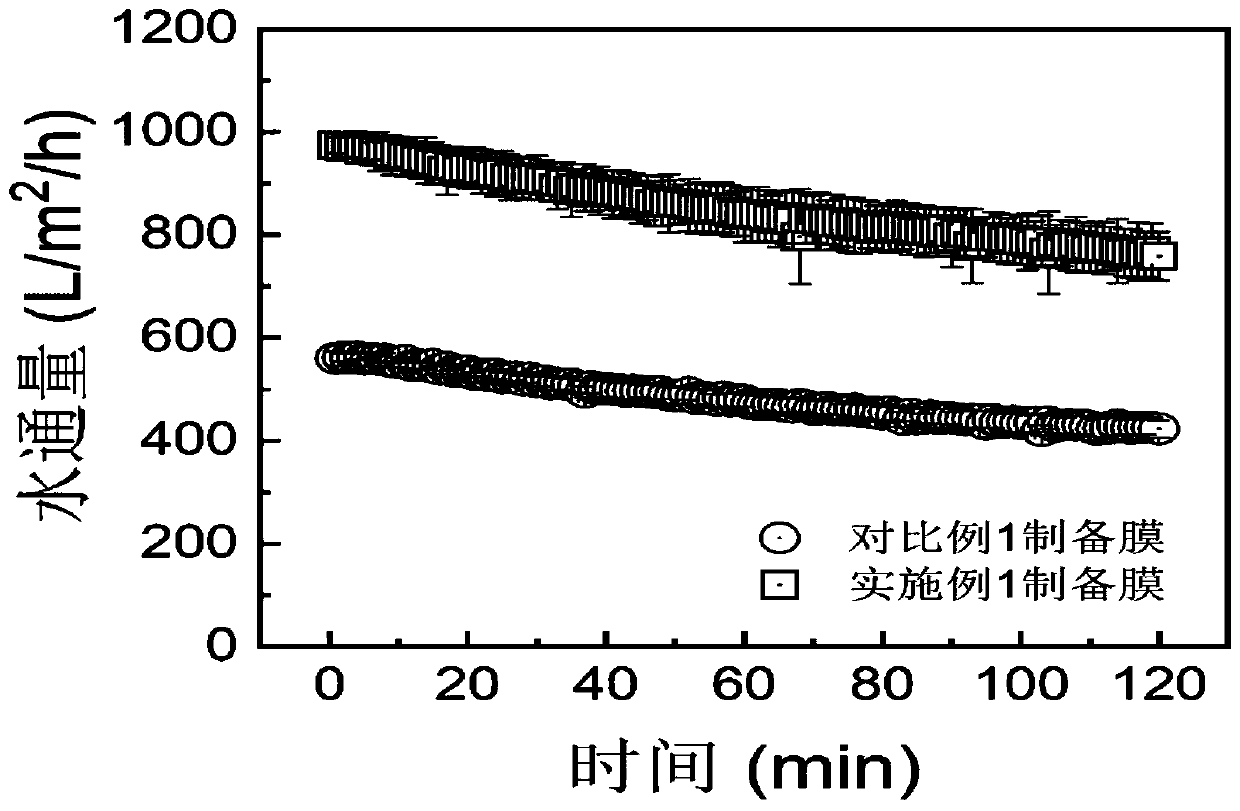

[0043] Example 1 Preparation of a polyvinylidene fluoride electrocatalytic ultrafiltration membrane based on graphite / titanium dioxide composite material

[0044] (1) Boil the hydrophilic carbon cloth in 0.1% dilute hydrochloric acid for 30 minutes, wash it with water for 5 times, and then dry it below 50°C for 1 hour to obtain a carbon cloth with a supporting layer function that removes surface impurities and strengthens the electrical conductivity of the carbon cloth;

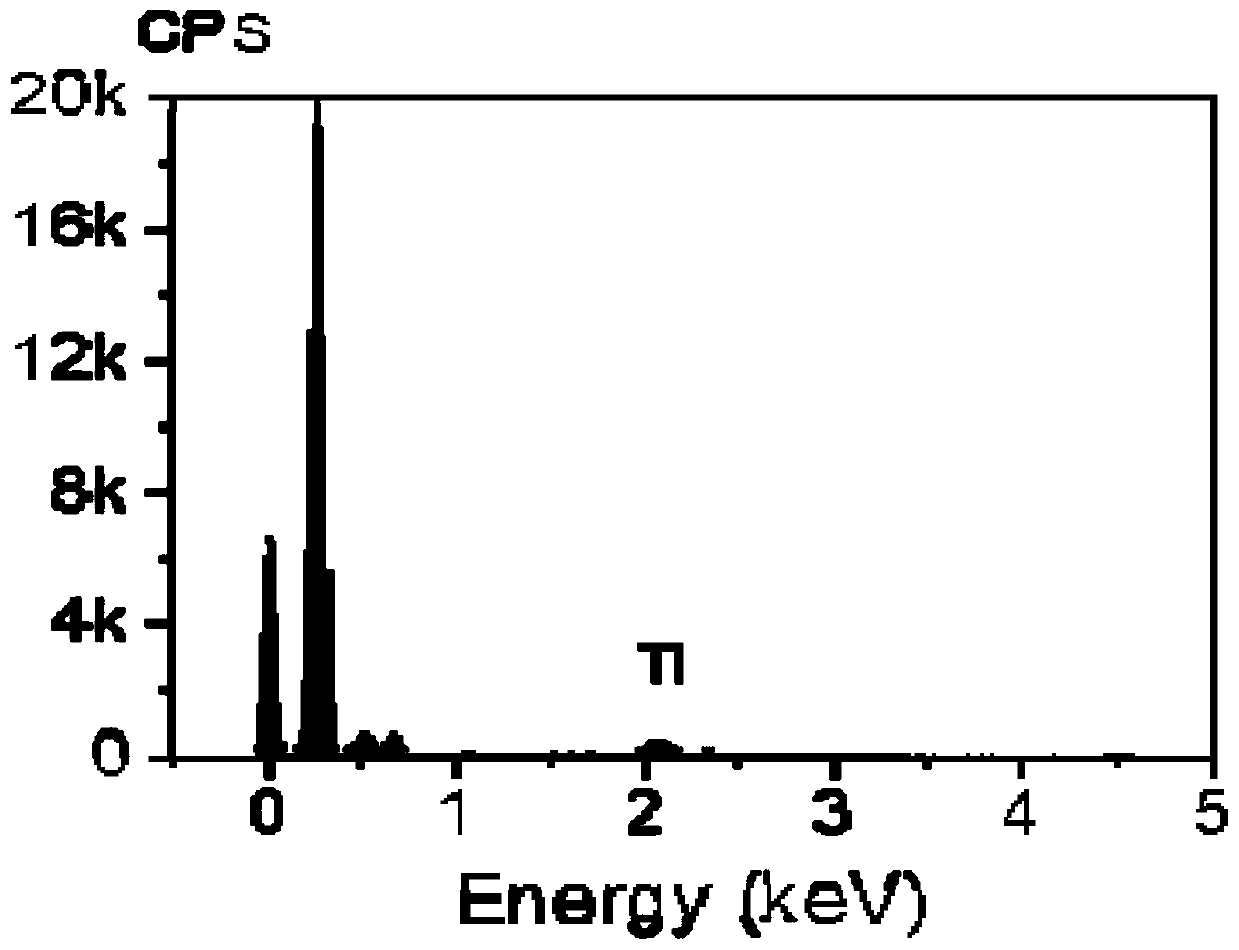

[0045] (2) Add 400 mg of graphite / titanium dioxide electrocatalytic composite material and 400 μL of Nafion solution to 40 mL of absolute ethanol, and ultrasonically disperse for 30 minutes; then arrange the dry carbon obtained in step (1) on the prepared graphite / titania composite material In the solution, lightly shake the load for 6 hours, and then dry it below 50°C to obtain a carbon cloth loaded with graphite / titanium dioxide composite material;

[0046] (3) Wash the carbon cloth obtained in step (2) in ...

Embodiment 2

[0051] A kind of method based on the polyvinylidene fluoride electrocatalytic ultrafiltration membrane of graphite / titania composite material as described in embodiment 1, difference is:

[0052] The amount of graphite / titania electrocatalytic composite material added in step 2 was 320 mg, and other conditions were the same.

Embodiment 3

[0054] A kind of method based on the polyvinylidene fluoride electrocatalytic ultrafiltration membrane of graphite / titania composite material as described in embodiment 1, difference is:

[0055] The amount of graphite / titania electrocatalytic composite material added in step 2 was 480 mg, and other conditions were the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com