P-doped solvothermal g-C3N4 photocatalyst preparation method

A photocatalyst and solvothermal technology, applied in the field of energy chemistry, can solve the problems of insignificant improvement of photocatalytic performance, ineffective doping of P elements, etc. Simple experimental setup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

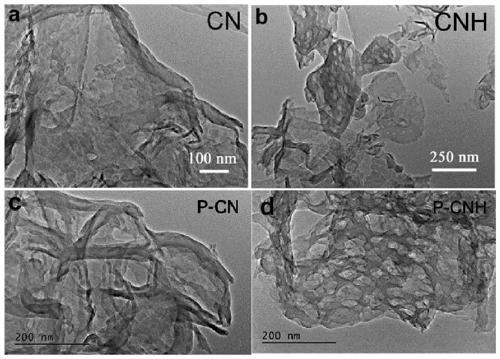

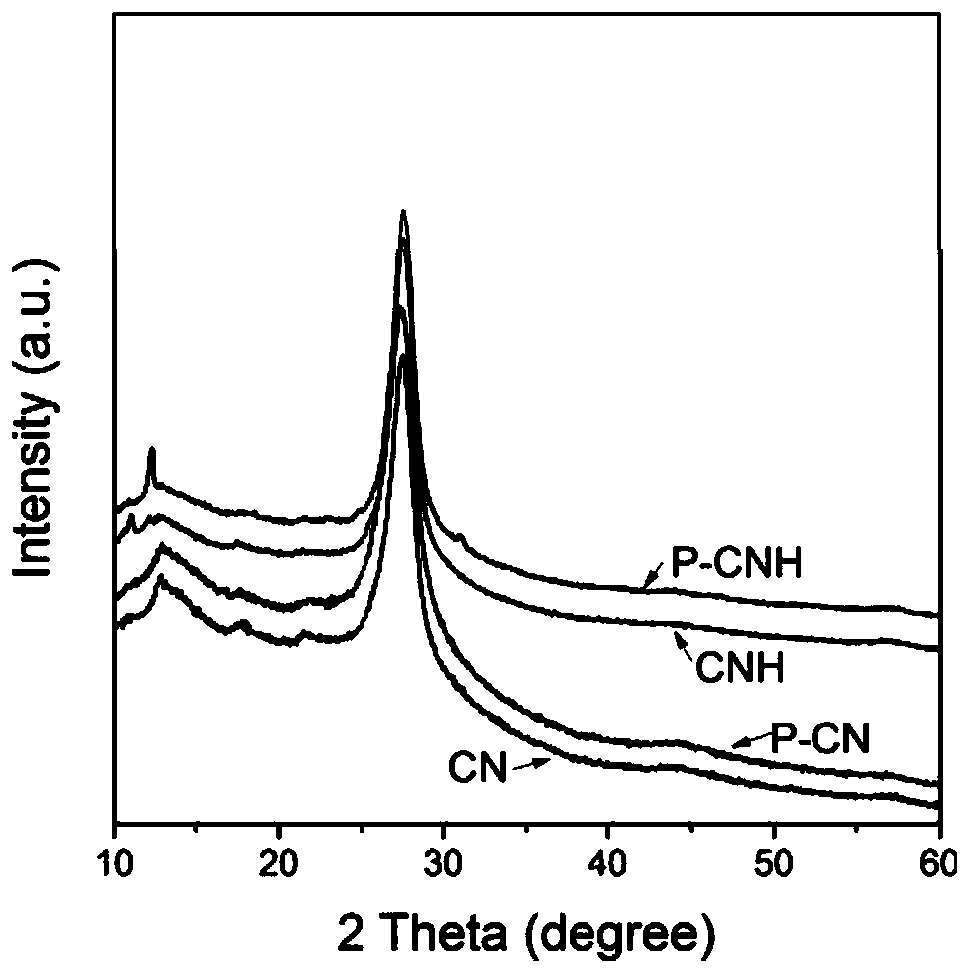

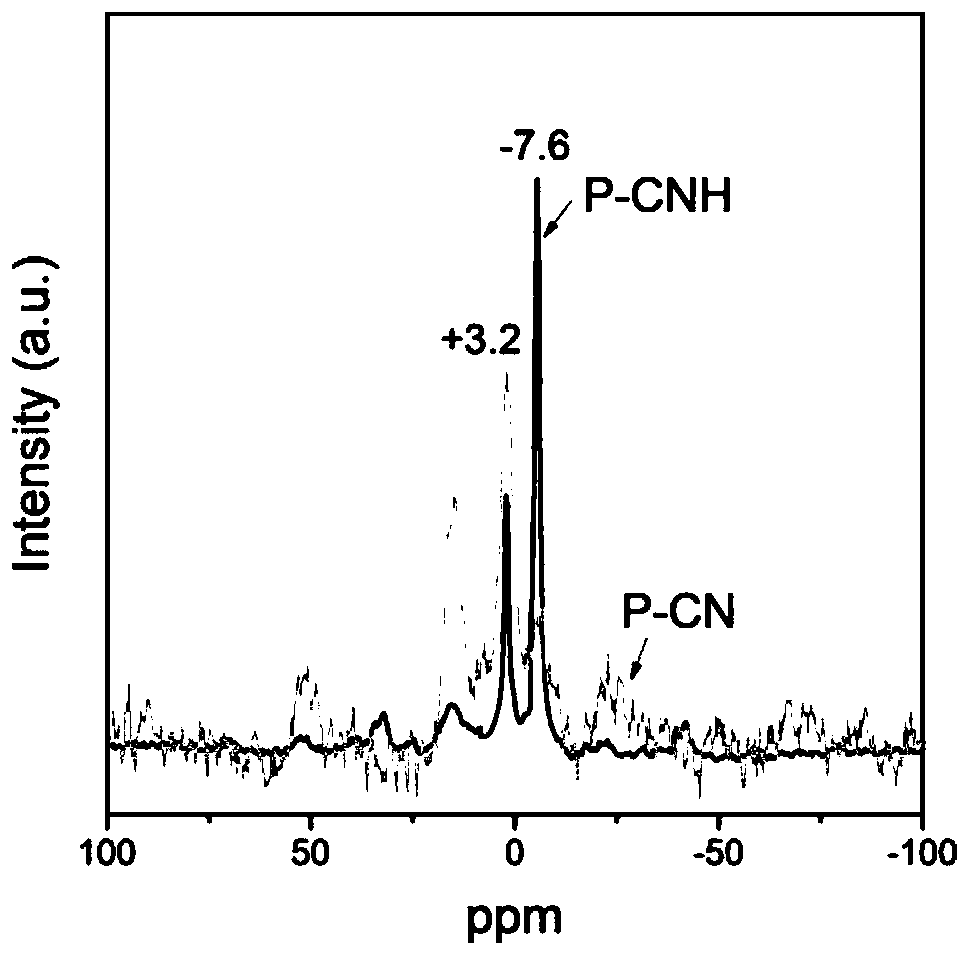

Image

Examples

preparation example Construction

[0029] A kind of P-doped solvothermal g-C of the present invention 3 N 4 The preparation method of photocatalyst comprises the steps:

[0030] S1. Put g-C 3 N 4 Disperse the powder in ethanol solution, and stir evenly after ultrasonic to obtain suspension A;

[0031] S2. Add an appropriate amount of water and ammonia water to the suspension A obtained in S1, stir evenly, heat and keep it at a certain temperature for a period of time, take it out, wash and dry, and obtain powder B;

[0032] S3. the powder B obtained in step S2 and a certain amount of sodium hydrogen hypophosphite (Na 2 HPO 2 ) was ground and mixed evenly, and after calcining at a certain temperature in a tube furnace with Ar gas, it was taken out, washed and dried, and finally P-doped solvothermal g-C was obtained. 3 N 4 catalyst of light. Among them, powder B and sodium hydrogen hypophosphite (Na 2 HPO 2 ) with a mixing mass ratio of 2:1, the calcination temperature under Ar gas is 300°C, the heating...

Embodiment 1

[0036] The P-doped solvothermal g-C prepared by the present invention 3 N 4 The method for photocatalyst, comprises the steps:

[0037] S1. Add 300mg of g-C 3 N 4 The powder was dispersed in 60mL of ethanol solution, ultrasonicated for 30min and then stirred for 1h to obtain suspension A;

[0038] S2. Add 1.25mL of water and 1.25mL of ammonia water to the suspension A obtained in S1, stir for 30min, put it into a hydrothermal kettle, heat the solvent at 140 degrees for 24h, cool naturally, take it out, wash and dry, and obtain powder B ; Drying is adjusted to 50 degrees vacuum drying for 8 hours.

[0039] S3. Mix the powder B (100mg) obtained in step S2 with 50mg of sodium hydrogen hypophosphite (Na 2 HPO 2 ) Grind and mix evenly, calcinate in a tube furnace with Ar gas at 300°C for 2 hours, take it out, wash and dry, and finally get P-doped solvothermal g-C 3 N 4 catalyst of light. Drying is adjusted to 50 degrees of vacuum drying for 8 hours.

Embodiment 2

[0041] S1. Add 500mg of g-C 3 N 4 The powder was dispersed in 60mL of ethanol solution, ultrasonicated for 30min and then stirred for 1h to obtain suspension A;

[0042] S2. Add 1.25mL of water and 1.25mL of ammonia water to the suspension A obtained in S1, stir for 30min, put it into a hydrothermal kettle, heat the solvent at 140 degrees for 24h, cool naturally, take it out, wash and dry, and obtain powder B ; Drying is adjusted to 60 degrees vacuum drying for 8 hours.

[0043] S3. Mix the powder B (100mg) obtained in step S2 with 50mg of sodium hydrogen hypophosphite (Na 2 HPO 2 ) Grind and mix evenly, calcinate in a tube furnace with Ar gas at 300°C for 2 hours, take it out, wash and dry, and finally get P-doped solvothermal g-C 3 N 4 catalyst of light. Drying is adjusted to 60 degrees of vacuum drying for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com