Denitration catalyst, method for preparing same and application of denitration catalyst

A denitration catalyst and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst deactivation, pore blockage, single structure, etc., achieving simple preparation process, preventing pore blockage, The effect of high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

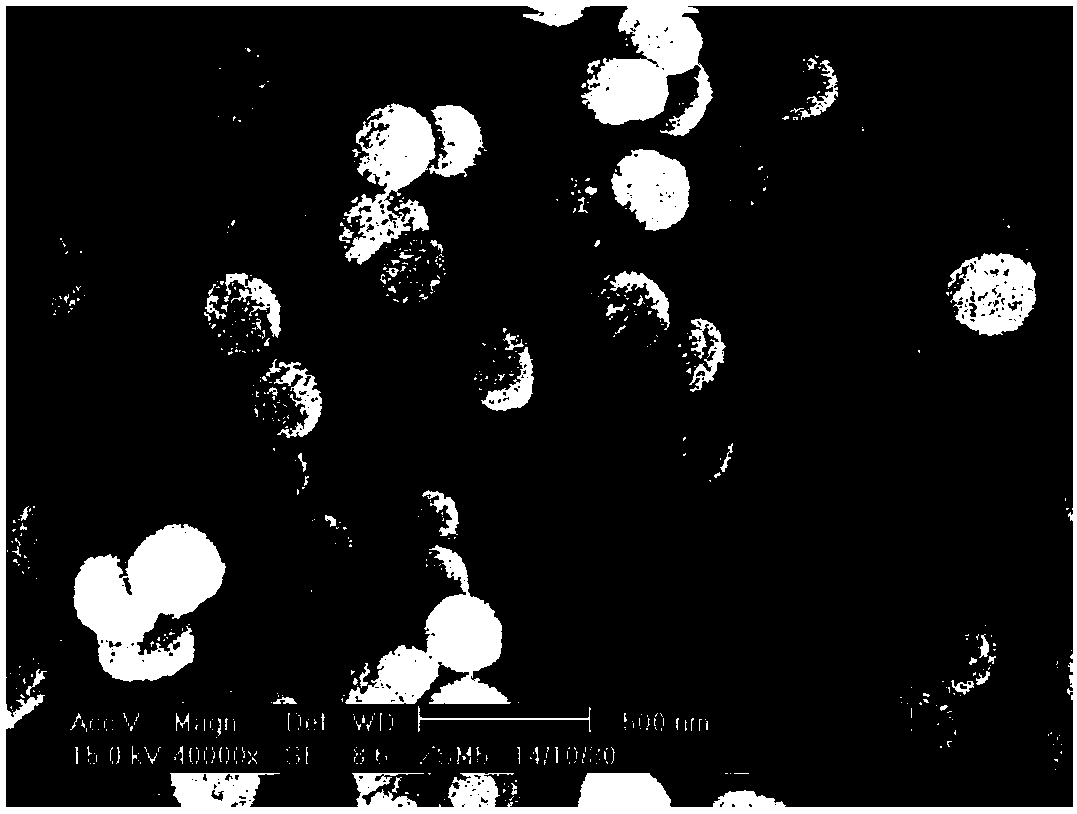

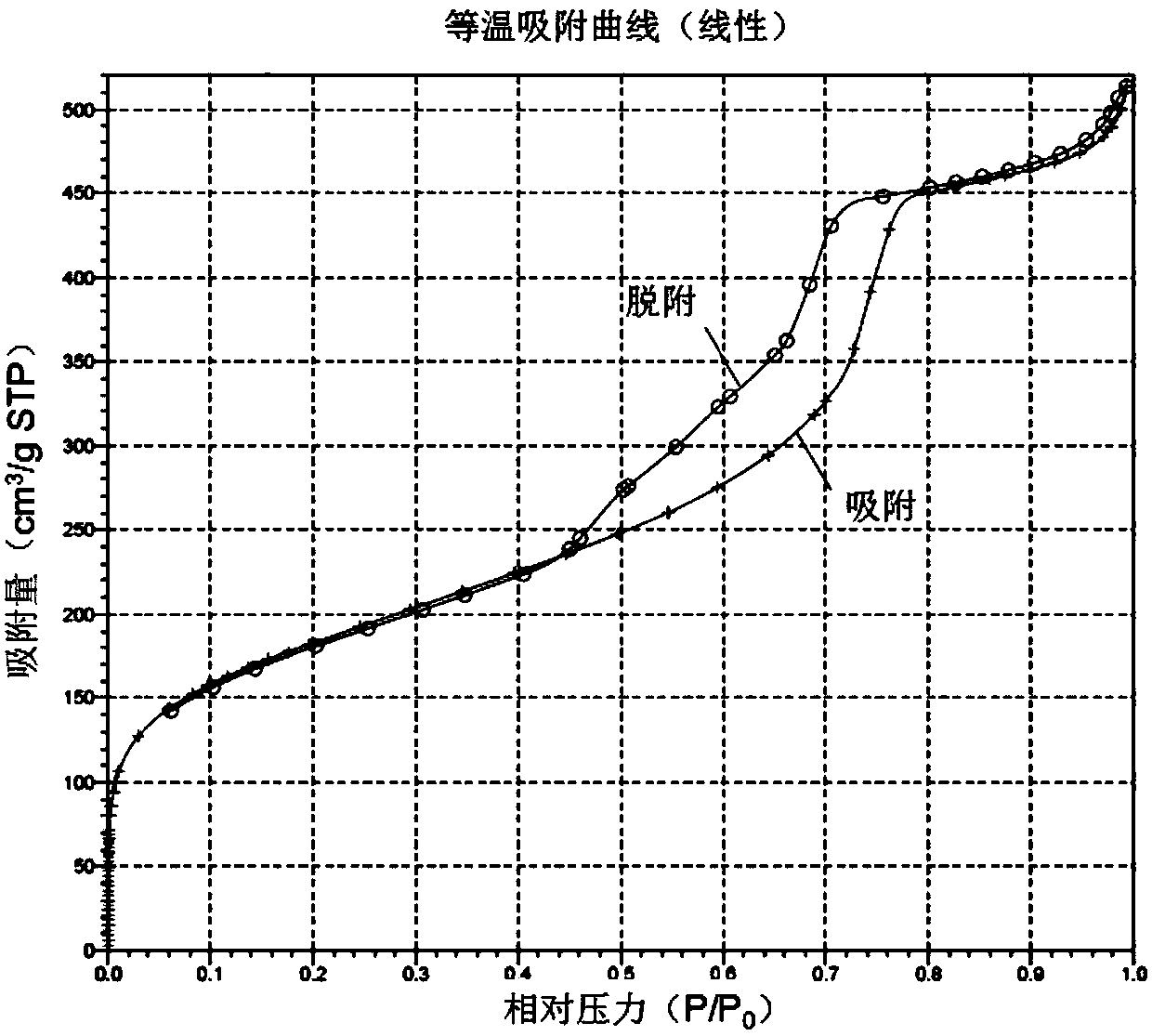

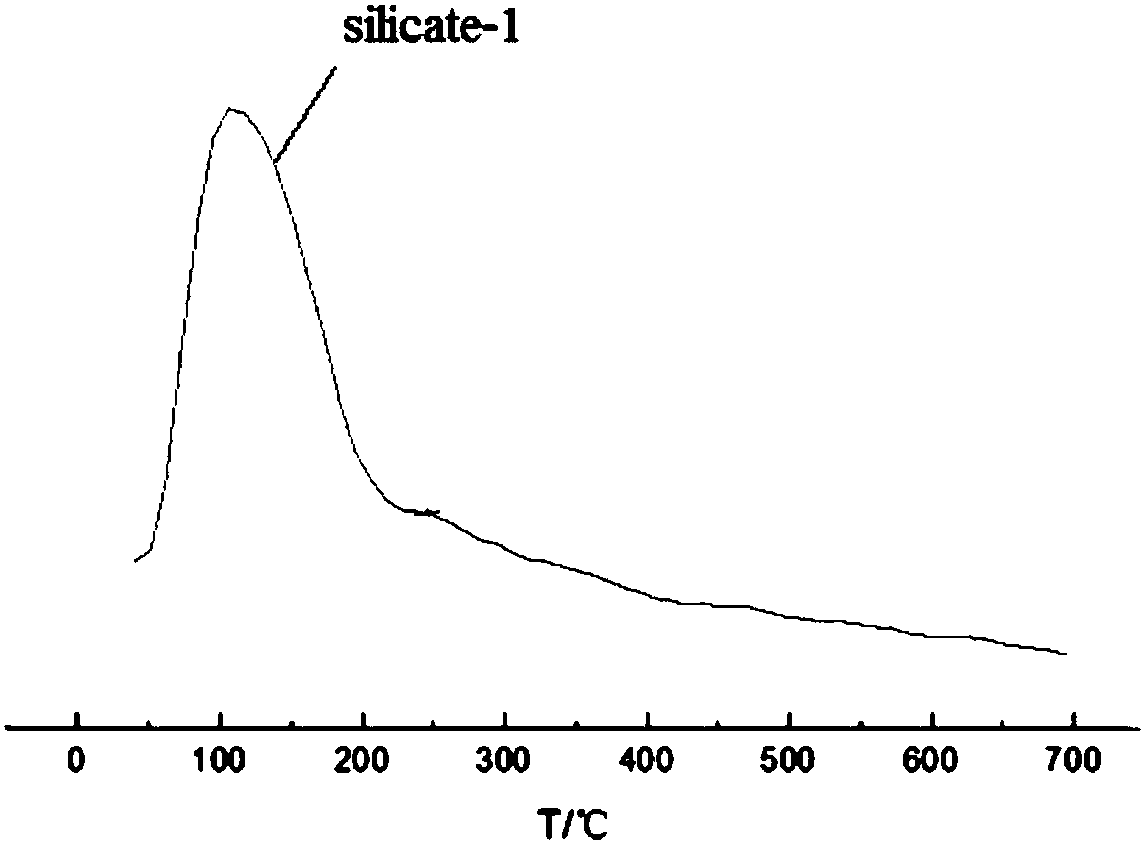

[0034] The preparation of multi-level porous all-silicon molecular sieve: adopt ethyl silicate-40 (wherein silicon dioxide mass content is 40%) TEOS is silicon source, tetrapropyl ammonium hydroxide (mass concentration 25%) TPAOH is template agent, with TEOS was slowly added to the aqueous solution of TPAOH at a mass ratio of 1:1, and magnetically stirred at room temperature for 2 h in the Erlenmeyer flask. Then it was transferred to a stainless steel hydrothermal kettle and reacted at a constant temperature of 180°C for 48h. After that, it was washed with deionized water, filtered, and dried at 120° C. for 12 hours. Furthermore, the prepared sample was placed in a tube furnace, and in an air atmosphere, the temperature was raised to 550° C. at a rate of 2° C. / min, and kept for 6 hours to obtain the hierarchical porous all-silicon molecular sieve silicalite-1. The SEM result of the all-silicon molecular sieve made is as follows figure 1 shown. N 2 The adsorption-desorption...

Embodiment 2

[0039] The preparation of all-silicon molecular sieve is the same as in Example 1.

[0040] The preparation of the catalyst is the same as in Example 1, except that the active components are loaded according to the loading ratio of 6% Mn and 6% Fe active components in mass percent.

[0041] The evaluation conditions of the catalyst are the same as those in Example 1. Using the catalyst prepared by the present invention, the conversion rate of NOx in the temperature range of 180-260° C. is 90%.

Embodiment 3

[0043] Preparation of multi-level porous all-silicon molecular sieve: use ethyl silicate-28 (wherein the mass content of silicon dioxide is 28%) TEOS as silicon source, tetrapropyl ammonium hydroxide TPAOH as template, with a mass ratio of 1:2 The ratio of TEOS was slowly added to the aqueous solution of TPAOH, in the Erlenmeyer flask, magnetically stirred at room temperature for 2h. Then the solution was transferred to a stainless steel hydrothermal kettle and reacted at a constant temperature of 160°C for 48h. After that, it was washed with deionized water, filtered, and dried at 120° C. for 12 hours. Further, the sample was placed in a tube furnace, and in an air atmosphere, the temperature was raised to 550° C. at a rate of 2° C. / min, and kept for 6 hours to obtain the hierarchical porous all-silicon molecular sieve silicalite-1.

[0044] Preparation of the catalyst: According to the loading ratio of the active components of 5% Ce, 6% Mn, and 4% Fe, respectively prepare a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com