Multi-functional hybrid ultra-filtration membrane as well as preparation method and application thereof

A multi-functional, ultrafiltration membrane technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve the problems of no oxidation selectivity, poor pollutant removal effect, etc. The effect of improving the removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

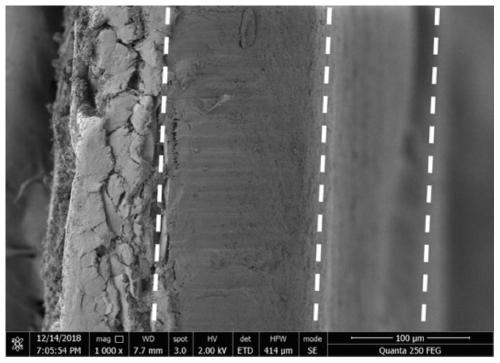

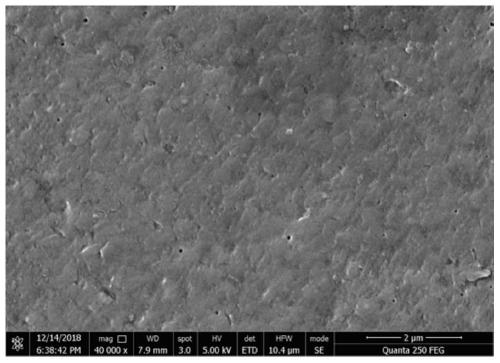

[0047] In this example, a method for preparing a multifunctional hybrid ultrafiltration membrane catalytic oxidation selectivity is provided to prepare a PVDF / MIL-PVDF membrane. The steps are as follows:

[0048] (1) Granular material preparation

[0049] MIL-53(Fe) particles were prepared, washed with water and alcohol several times in sequence, dried and activated by heating in vacuum.

[0050] (2) Preparation of blended casting solution

[0051] Dissolve 0.5g of polyvinylidene fluoride (PVDF) into 5mL of N,N-dimethylformamide, mix well until the polymer is completely dissolved, and dissolve 0.5g of MIL-53(Fe) particles in step (1) Add it into the solution, mix well, add 0.25g of polyvinylpyrrolidone, mix well until completely dissolved, and obtain a blended casting solution.

[0052] (3) Preparation of support layer

[0053] The blended film casting solution obtained in step (2) is manually applied and scraped on the non-woven fabric by a film scraper, and the organic so...

Embodiment 2

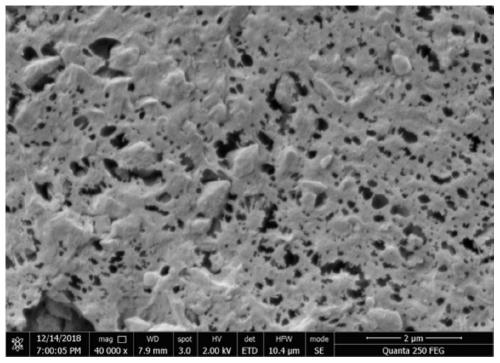

[0087] In this embodiment, a kind of preparation method that improves the catalytic oxidation selectivity of multifunctional hybrid ultrafiltration membrane is provided, and chitosan / Fe 2 o 3 - Polyethersulfone membrane, as follows:

[0088] (1) Granular material preparation

[0089] Preparation of Fe 2 o 3 Granules, pickled, then washed with water until neutral, dried and roasted at high temperature.

[0090] (2) Preparation of blended casting solution

[0091] Dissolve 0.5g of polyethersulfone into 5mL of N,N-dimethylacetamide, mix well until the polymer is completely dissolved, and dissolve 0.5g of Fe in step (1) 2 o 3 Add the particles into the solution, mix well, add 0.25g of polyethylene glycol, mix well until completely dissolved, and obtain a blended casting solution.

[0092] (3) Preparation of support layer

[0093] The blended casting solution obtained in step (2) is scraped on a glass plate by automatic scraping film, and the organic solvent is removed by n...

Embodiment 3

[0099] In this example, a preparation method for improving the catalytic oxidation selectivity of a multifunctional hybrid ultrafiltration membrane is provided, and a polyethersulfone / MIL-53(Cu)-polyacrylonitrile membrane is prepared. The steps are as follows:

[0100] (1) Granular material preparation

[0101] MIL-53(Cu) particles were prepared, washed several times with water and alcohol successively, dried and activated by heating in vacuum.

[0102] (2) Preparation of blended casting solution

[0103] Dissolve 0.5g of polyacrylonitrile into 5mL of N,N-dimethylformamide, mix well until the polymer is completely dissolved, add 0.5g of MIL-53(Cu) particles in step (1) to the solution , fully mixed evenly, adding 0.25g of polyvinylpyrrolidone, fully mixed until completely dissolved, to obtain a blended casting solution.

[0104] (3) Preparation of support layer

[0105] The blended casting solution obtained in step (2) was manually scraped on the aluminum foil with a film s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com