Degradable antibacterial preservative film product and preparation method thereof

A technology for fresh-keeping film and products, which is applied in the field of degradable antibacterial fresh-keeping film products and its preparation, which can solve the problems of difficult to decompose plastic film products, weak antibacterial performance, and short timeliness, and achieve safe antibacterial performance and long-term antibacterial Performance, the effect of increasing the preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

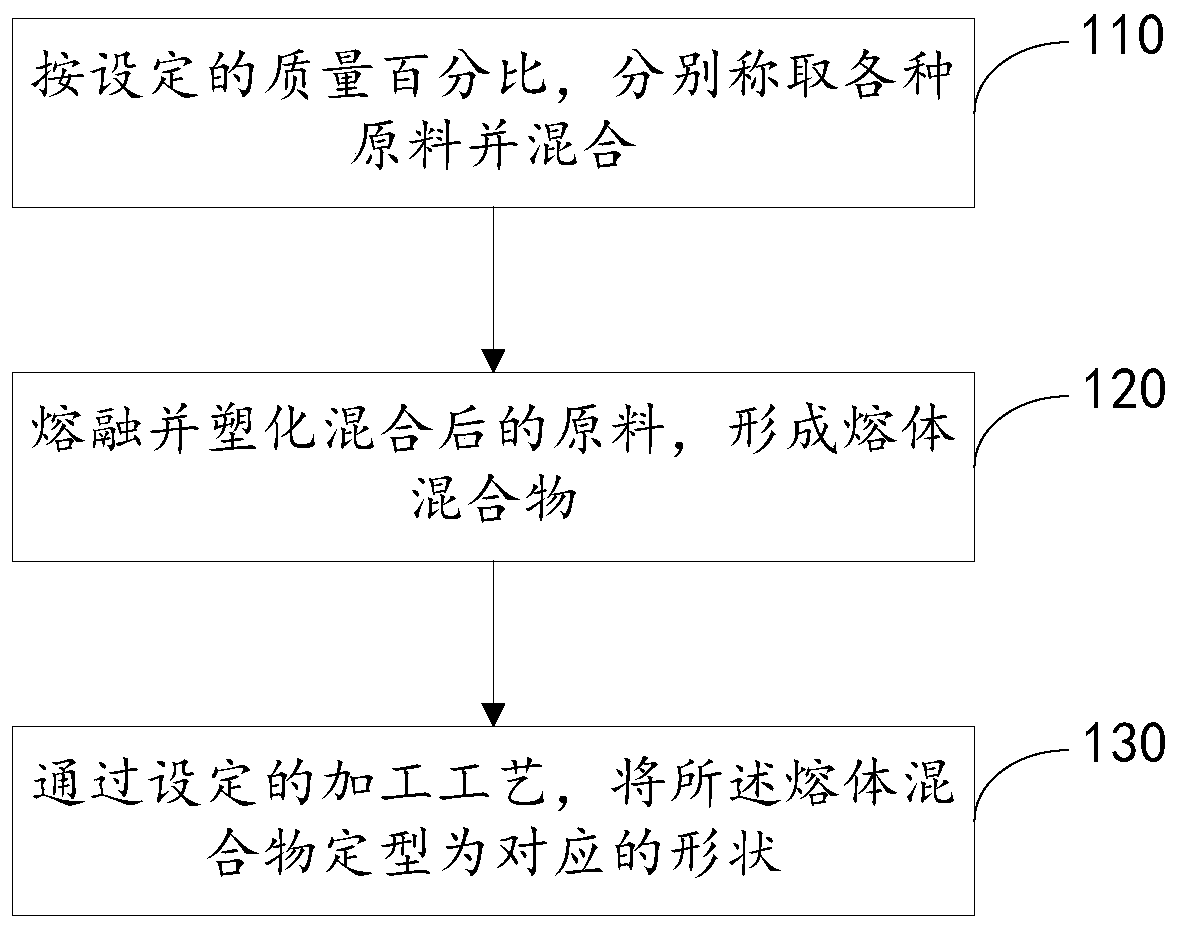

[0031] figure 1 The method flow chart of the preparation method of the degradable antibacterial fresh-keeping film product provided by the embodiment of the present invention. The application of the preparation method can provide a packaging material with high efficiency, broad spectrum, long-term effect and safe antibacterial performance, so that it can reduce the amount of antiseptic additives used and increase the storage time. Such as figure 1 Shown, described preparation method comprises the steps:

[0032] 110. According to the set mass percentage, weigh and mix various raw materials respectively.

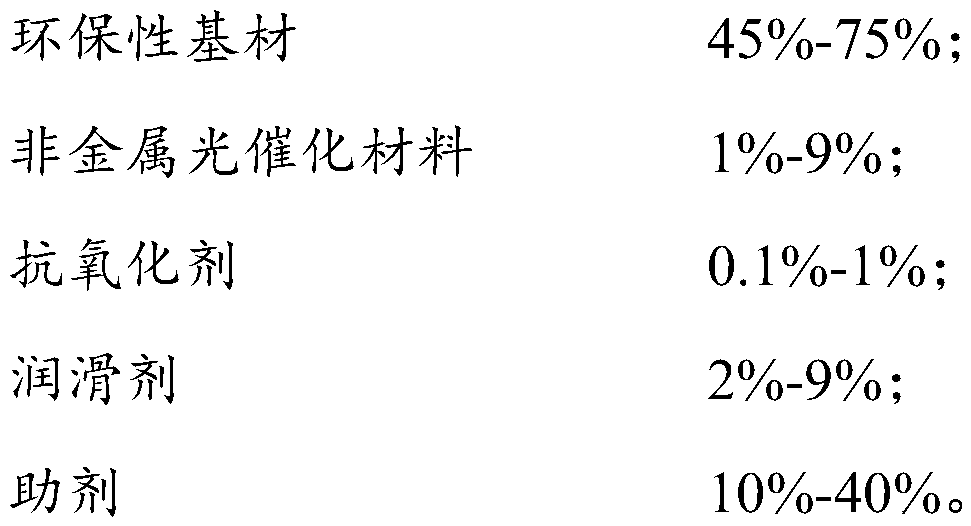

[0033] In this embodiment, the raw materials include environmentally friendly substrates, C3N4 and other non-metallic photocatalytic materials, antioxidants, lubricants and additives. The mass percentage ranges set for each raw material are: 48%-75% of environmentally friendly substrates, 1%-9% of C3N4 and other non-metallic photocatalytic materials, 0.1%-1% of antioxidant...

Embodiment 1

[0058] 1) Take raw materials by the following mass percentages:

[0059]

[0060]

[0061] 2) Adding the weighed raw materials into an injection molding machine for mixing, melting and plasticizing into a melt mixture.

[0062] 3) Injecting the melt mixture into a molding mold to form a hollow green body.

[0063] 4) Passing high-pressure gas into the hollow embryo body to make it expand and shape in the forming mold to prepare nano-antibacterial packaging products.

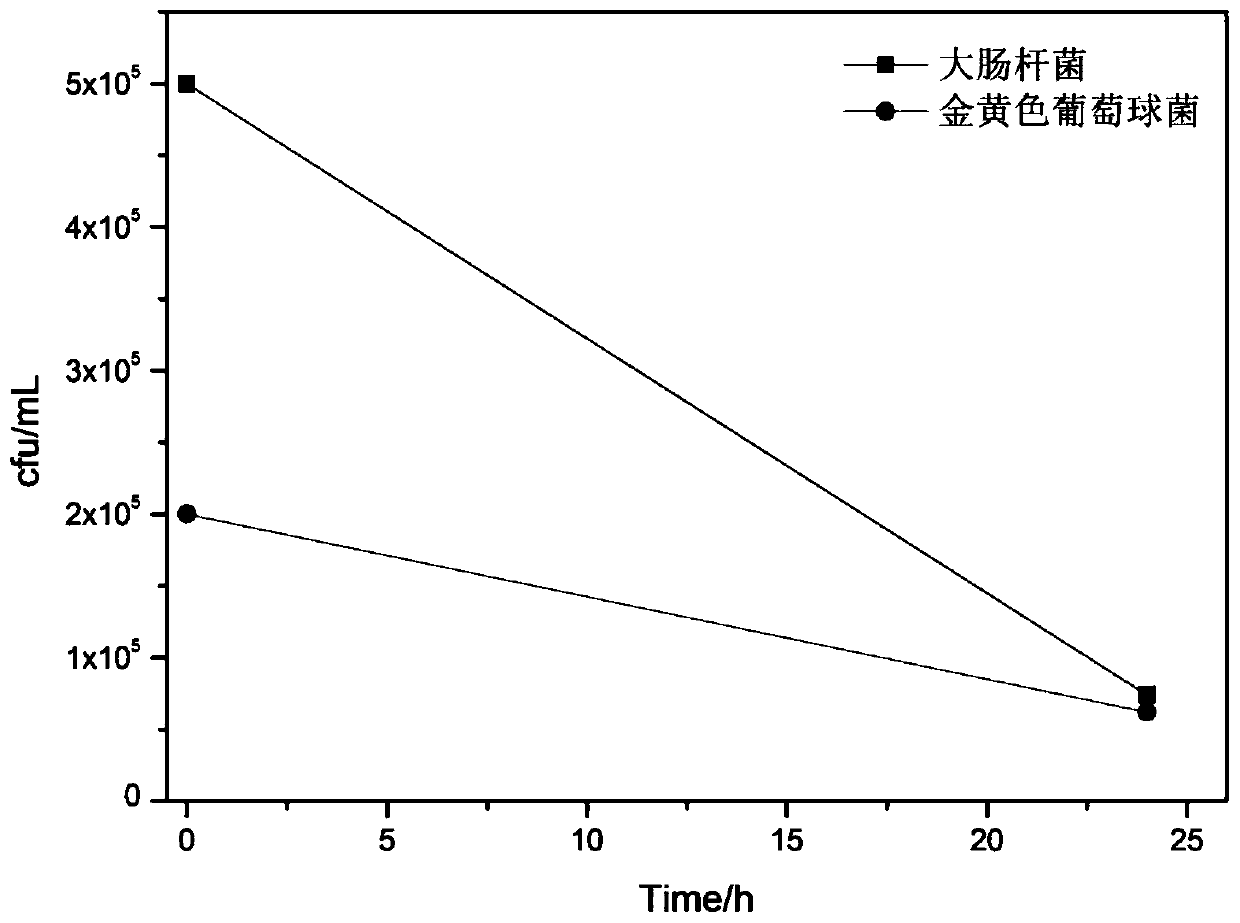

[0064] The antibacterial packaging product of the embodiment of the present invention has excellent antibacterial performance, and can realize complete biodegradation, and has no pollution to the environment. Food preservation film, vegetable preservation box, disposable lunch box, agricultural mulch film, medicine storage box, etc.

Embodiment 2

[0066] 1) Take raw materials by the following mass percentages:

[0067]

[0068] 2) Adding the weighed raw materials into an injection molding machine for mixing, melting and plasticizing into a melt mixture.

[0069] 3) Injecting the melt mixture into a molding mold to form a hollow preform.

[0070] 4) Passing high-pressure gas into the hollow preform to make it expand and shape in the forming mold to prepare nano antibacterial packaging products.

[0071] The packaging product of the embodiment of the present invention has antibacterial effect and continuous antibacterial effect. It also has excellent antibacterial effect not only under the condition of light, but also under the condition of no light. In fields such as medicine, it is specifically applicable to fruit fresh-keeping bags / films, food fresh-keeping films, vegetable fresh-keeping boxes, disposable lunch boxes, agricultural mulching films, medicine storage boxes, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com