Continuous Production Process of Oxygenated Composite Hydrocarbon Wax

A production process and technology of hydrocarbon wax, which is applied in the field of preparation of oxidized composite hydrocarbon wax, can solve the problems of low output per unit time, low quality of high-density oxidized polyethylene wax, and low utilization rate of equipment in the oxidation production process, and achieve a small footprint , Reduce labor intensity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

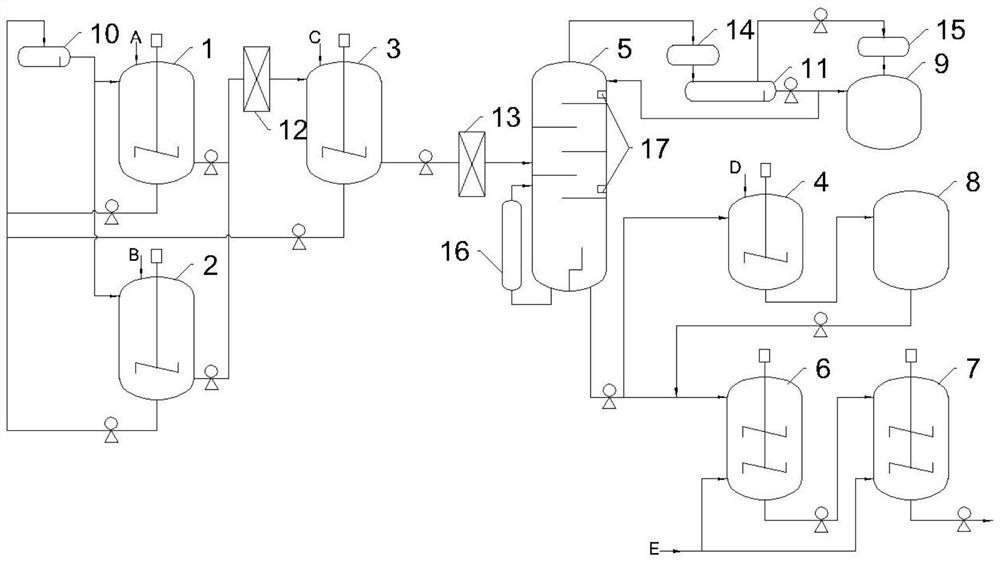

[0049] In this embodiment, hydrocarbon wax is used according to the mass ratio of 70 degrees Fischer-Tropsch wax: imported Middle East oligomer wax F13 = 1:0.5, and added to the dehydration kettle.

[0050] The operating temperature of the first dehydration kettle 1 and the second dehydration kettle 2 is 140°C and the operating temperature of the decolorization kettle 5 is 145°C; the operating temperature at the bottom of the split tower 5 is 155°C to 160°C; At point 17, the operating temperature of the bottom tray is 140°C to 145°C, and the operating temperature of the top tray is 125°C to 130°C.

[0051] The operating pressure in the split tower 5 is controlled at 60KPa.

[0052] The oxidation reaction efficiency of compound hydrocarbon wax is 93.2, the acid value is 6 and the color is yellowish. The molecular weight range of the composite hydrocarbon wax is 800-4000.

Embodiment 2

[0054] In this embodiment, the mass ratio of the composite hydrocarbon wax is 60° paraffin wax: 80° Fischer-Tropsch wax = 1:1.

[0055] The operating temperature of the first dehydration kettle 1 and the second dehydration kettle 2 is 95°C and the operating temperature in the decolorization kettle 5 is 105°C; the operating temperature at the bottom of the split tower 5 is 150°C to 155°C; At point 17, the operating temperature of the bottom tray is 135°C to 140°C, and the operating temperature of the top tray is 123°C to 128°C.

[0056] The operating pressure in the split tower 5 is controlled at 55KPa. All the other are the same as in Example 1.

[0057] The composite hydrocarbon wax has an oxidation reaction efficiency of 94, an acid value of 7 and a light yellow color. The molecular weight range of the composite hydrocarbon wax is 400-800.

Embodiment 3

[0059] In this embodiment, the mass ratio of composite hydrocarbon wax is 60° paraffin wax: 80° Fischer-Tropsch wax: imported Korean oligomer DN400 = 0.5:1:0.3.

[0060] The operating temperature of the first dehydration kettle 1 and the second dehydration kettle 2 is 130°C and the operating temperature in the decolorization kettle 5 is 135°C; the operating temperature at the bottom of the split tower 5 is 150°C to 155°C; At point 17, the operating temperature of the bottom tray is 136°C to 140°C, and the operating temperature of the top tray is 123°C to 128°C.

[0061] The operating pressure in the split tower 5 is controlled at 40KPa. All the other are the same as in Example 1.

[0062] The oxidation reaction efficiency of compound hydrocarbon wax is 92.6, the acid value is 9 and the color is light yellow. The molecular weight range of the composite hydrocarbon wax is 750-4500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation efficiency | aaaaa | aaaaa |

| oxidation efficiency | aaaaa | aaaaa |

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com