Composite gel polymer electrolyte preparation method and lithium ion battery

A gel polymer and lithium-ion battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as poor mechanical properties, low room temperature ionic conductivity, and application limitations, and achieve low cost and room temperature ionic conductivity The effect of high efficiency and wide electrochemical voltage window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

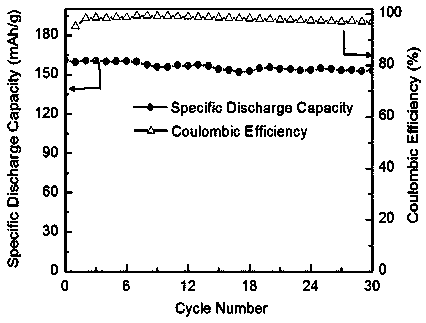

[0039] The specific content of the present invention will be further elaborated below in conjunction with the drawings and specific embodiments.

[0040] A kind of composite gel polymer electrolyte, its preparation method comprises the following steps:

[0041] (1) Pretreat the polymer matrix and completely dissolve it in an organic solvent;

[0042] (2) Adding a crosslinking agent to the solution obtained in step (1) for dissolution and dispersion;

[0043] (3) adding inorganic fillers to the solution obtained in step (2) and dispersing;

[0044] (4) adding lithium salt to the solution obtained in step (3) for dissolution to obtain a mixed glue;

[0045] (5) The organic solvent in the mixed glue obtained in step (4) is volatilized and dried on the substrate to form a film, and a composite gel polymer electrolyte is prepared.

[0046] In the step (1), the polymer matrix is polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP), polyacrylonitrile (PAN), polymethyl methacry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com