Aircraft and structure battery component of aircraft

An aircraft and battery technology, applied to aircraft parts, chords/stringers, transportation and packaging, etc., can solve the problems of less charge and discharge cycles, capacitance attenuation, and severe battery volume expansion, etc., to reduce strength/rigidity constraints , reduce weight, reduce the effect of trim constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

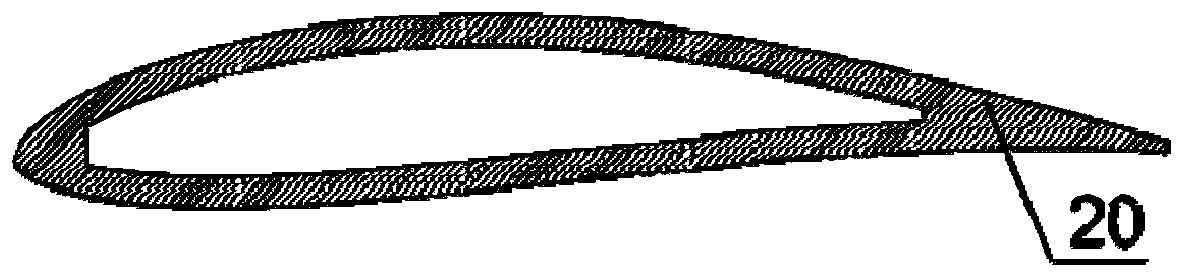

[0070] like Figure 5 As shown, the functional laminate 25 includes an anode 31, a diaphragm 32 and a cathode 33; the first layer structure and the third layer serve as the anode 31 and cathode 33 of the battery respectively, and the middle layer structure serves as the diaphragm 32 of the battery.

[0071] (Each layer is a prepreg. The prepreg is a fabric prepreg, that is, there are first fibers 51 in the anode, third fibers 53 in the cathode, and second fibers 55 in the separator 32)

[0072] The anode includes an anode matrix 52 and first fibers 51 in the anode matrix; the cathode includes a cathode matrix and third fibers 53 in the cathode matrix; the membrane 32 includes a membrane matrix 21 and second fibers 55 in the membrane.

[0073] The anode (polymer) matrix 52 of the anode, the membrane (polymer) matrix 56 of the membrane, and the cathode (polymer) matrix 54 of the cathode are all electrically insulating. Can be epoxy, rubber or a resin-rubber mixture. Other poly...

specific Embodiment approach 2

[0082]The functional laminate 25 includes an anode 31 , a separator 32 and a cathode 33 .

[0083] The anode 31 is a fiber bundle or several fiber bundles not in contact with each other, and the fiber bundle is a fiber filament or a plurality of fiber filaments with electrical conductivity.

[0084] Diaphragm 32 is a solid polymer electrolyte on the periphery of anode 31; it can be coated on the periphery of anode 31.

[0085] The cathode 33 is a polymer matrix containing electrochemically active substances and is connected to a metal current collector.

[0086] like Image 6 Shown, a plurality of conductive fiber bundles, coated with a solid polymer electrolyte; immersed in a polymer matrix containing electrochemically active particles.

[0087] The anode of the battery is directly used as a current collector or connected to a metal current collector (the current collector is in Image 6 not shown in). The number and arrangement of fiber bundles are not limited to Image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com