Method for preparing compound fertilizer by utilizing lignin extracted from cotton stalks

A lignin and compound fertilizer technology, applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of difficult handling and many impurities, and achieve the effect of simple process, safe operation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

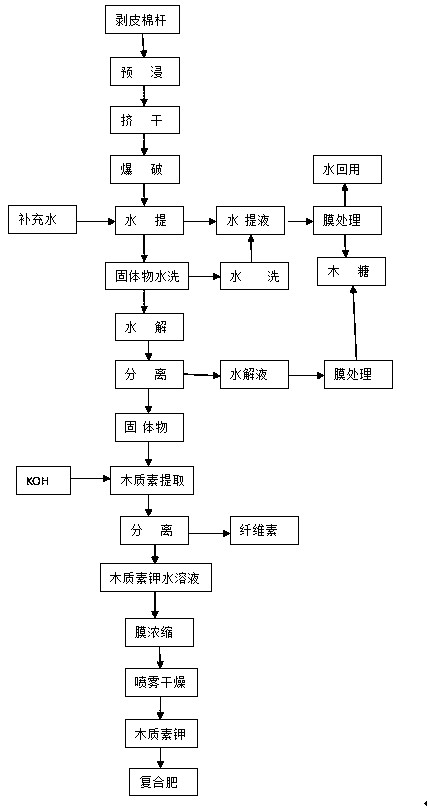

[0034] A method for preparing compound fertilizer from lignin extracted from cotton stalks, comprising the following steps:

[0035] (1) Pretreatment: After separating the collected cotton stalk sheath and core, cut into length 8-12cm, after screening, enter the continuous presoaker and contain the aqueous solution of dilute sulfuric acid that mass concentration is 0.4% to carry out presoaking, solid-liquid The ratio is 1:6. The presoaking temperature is 70°C and the time is 0.5h.

[0036] (2) Squeeze dry: dehydrate the material after soaking in the continuous prepreg machine, so that its water content is 40%;

[0037] (3) Steam explosion treatment: Put the dehydrated cotton stalks into the steam explosion device for steam explosion treatment; during steam explosion treatment, first pressurize to 2.0MPa with steam, then pressurize to 3.5MPa with compressed air, and maintain the time for 120s , to achieve instant explosion.

[0038] (4) Extracting xylose by water washing: extr...

Embodiment 2

[0045] The method for preparing compound fertilizer from lignin extracted from cotton stalks comprises the following steps:

[0046] (1) Pretreatment: After the collected cotton stalks are separated, they are cut into lengths of 8-12 cm. After screening, they are entered into a continuous presoaker and presoaked with an aqueous solution containing 0.4%% dilute sulfuric acid. The solid-to-liquid ratio is 1: 6. The temperature is 70°C.

[0047] (2) Squeeze dry: dehydrate the material after soaking in the continuous prepreg machine, so that its water content is 40%;

[0048] (3) Steam explosion treatment: Put the dehydrated cotton stalks into the steam explosion device for steam explosion treatment; during steam explosion treatment, first pressurize to 2.0MPa with steam, then pressurize to 3.5MPa with compressed air, and maintain the time for 120s , explode instantly.

[0049] (4) Extraction of xylose by water washing: extract xylose from the steam-exploded material with water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com