Rust converter for online dip-coating rust prevention of building steel parts and construction method thereof

A technology for building steel and rust transfer agent, applied in coatings, anti-corrosion coatings, etc., can solve the problems of incomplete rust removal, high cost, large pollution, etc., and is suitable for large-scale promotion and application, long outdoor service life, preparation Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

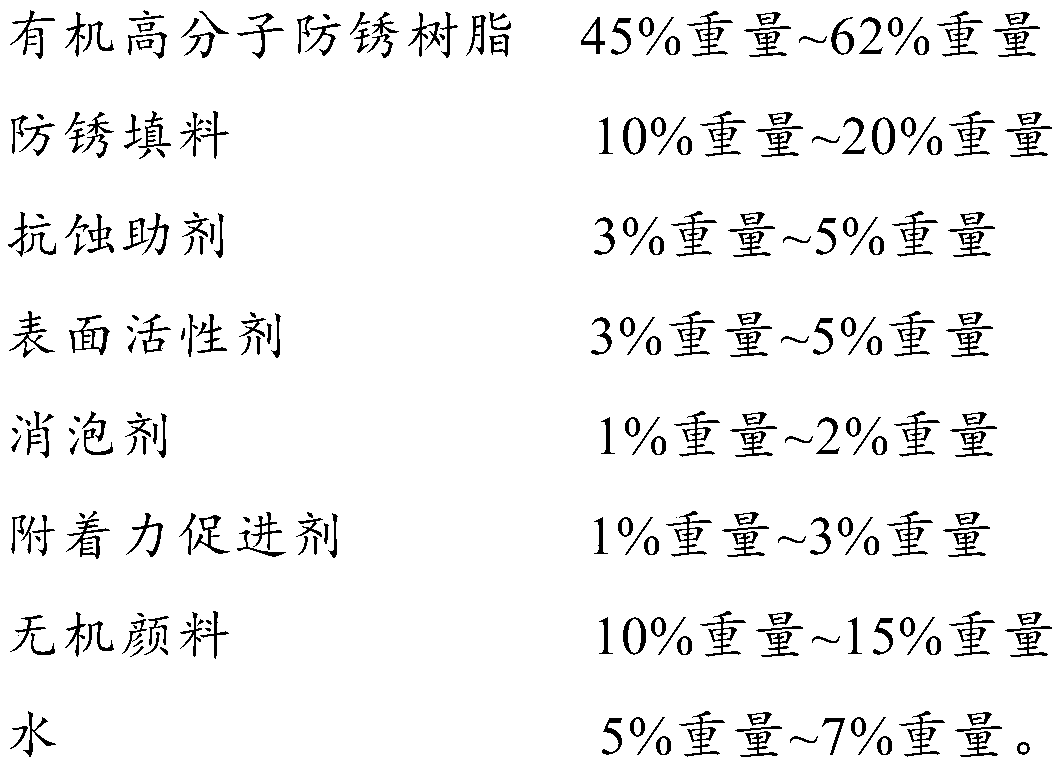

[0038]

[0039] Wherein the organic polymer antirust resin (purchased from Wuxi Changhao Chemical Industry) is formed by grafting phytic acid ester and tannic acid, and phytic acid ester is 45% by weight, and tannic acid is 17% by weight; The filler is aluminum tripolyphosphate; the anti-corrosion additive is glycidoxypropyl trimethoxysilane; the surfactant includes polyethylene glycol dioleate and alkylphenol polyoxyethylene ether, polyethylene glycol dioleate Ester 2% by weight, alkylphenol polyoxyethylene ether is 3% by weight; defoamer is dimethicone; adhesion promoter is dihydroxyethyl methacrylate phosphate; inorganic pigment is rutile Titanium dioxide; water is deionized water.

[0040] Mix and stir the above-mentioned components evenly to obtain the anti-rust agent for on-line dip-coating of construction steel parts.

[0041] When in use, dilute the above-mentioned rust-converting agent for on-line dip-coating rust-proofing of construction steel parts with water as...

Embodiment 2

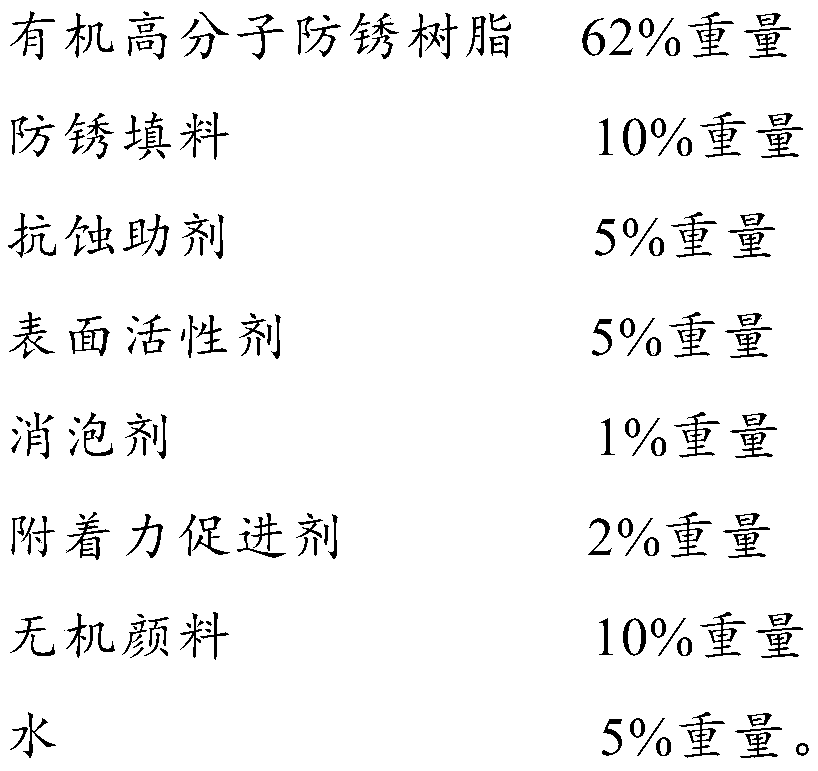

[0044]

[0045] Wherein the organic polymer antirust resin (purchased from Wuxi Changhao Chemical Industry) is formed by grafting phytic acid ester and tannic acid, wherein phytic acid ester is 40% by weight, and tannic acid is 15% by weight; The filler is aluminum tripolyphosphate; the anti-corrosion additive is glycidoxypropyl trimethoxysilane; the surfactant includes polyethylene glycol dioleate and alkylphenol polyoxyethylene ether, polyethylene glycol dioleate Ester 1% by weight, alkylphenol polyoxyethylene ether is 2% by weight; defoamer is dimethicone; adhesion promoter is dihydroxyethyl methacrylate phosphate; inorganic pigment is rutile Titanium dioxide; water is deionized water.

[0046] Mix and stir the above-mentioned components evenly to obtain the anti-rust agent for on-line dip-coating of construction steel parts.

[0047] When in use, dilute the above-mentioned rust-converting agent used for on-line dip-coating rust-proofing of construction steel parts with...

Embodiment 3

[0050]

[0051]

[0052] Wherein the organic polymer antirust resin (purchased from Wuxi Changhao Chemical) is formed by grafting phytic acid ester and tannic acid, wherein phytic acid ester is 35% by weight, and tannic acid is 10% by weight; The filler is aluminum tripolyphosphate; the anti-corrosion additive is glycidoxypropyl trimethoxysilane; the surfactant includes polyethylene glycol dioleate and alkylphenol polyoxyethylene ether, polyethylene glycol dioleate Ester 1% by weight, alkylphenol polyoxyethylene ether is 3% by weight; defoamer is dimethicone; adhesion promoter is dihydroxyethyl methacrylate phosphate; inorganic pigment is rutile Titanium dioxide; water is deionized water.

[0053] Mix and stir the above-mentioned components evenly to obtain the anti-rust agent for on-line dip-coating of construction steel parts.

[0054] When in use, dilute the above-mentioned rust-converting agent used for on-line dip-coating rust-proofing of construction steel parts w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com