Oil-soluble latex blocking agent and preparation method thereof

A plugging agent and oil-soluble technology, which is applied in the field of oil-soluble emulsion plugging agent and its preparation, can solve the problems of plugging failure and slow plugging, and achieve the goal of preventing crack opening, good pressure bearing performance and ensuring stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

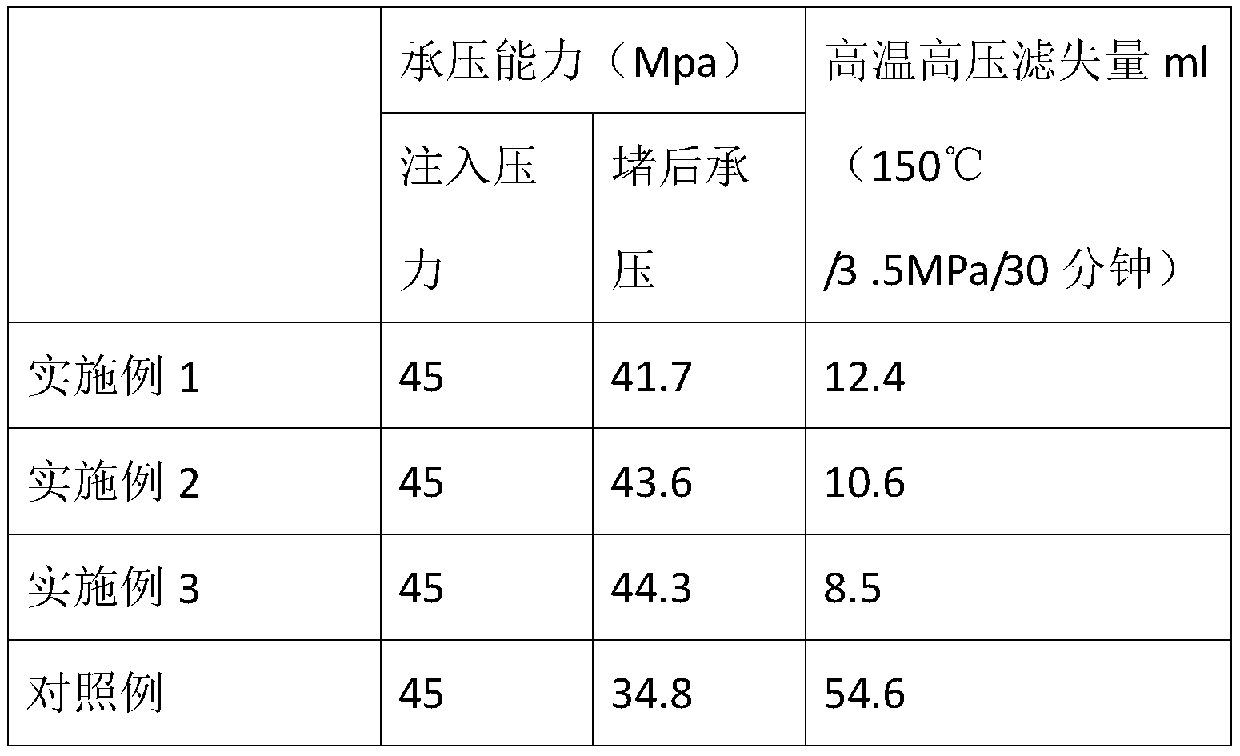

Examples

Embodiment 1

[0039] 1. This embodiment provides an oil-soluble emulsion plugging agent, which is mainly prepared from the following components in parts by mass:

[0040] 50 parts of butadiene monomer, 45 parts of styrene monomer, 15 parts of alkyl acrylate, 10 parts of glycidyl acrylate, 1.5-3 parts of sodium methacrylate hydroxypropyl sulfonate, 110 parts of deionized water, disulfide 0.2 parts of diisopropyl xanthate, 0.02 parts of antioxidant Irganox1098, 10 parts of white oil, 0.28 parts of azobicyclohexylcarbonitrile, 0.01-0.025 parts of hydroxyethylethylenediaminetriacetic acid (HEDTA), two 0.1-0.5 parts of sodium methyl disulfide carbamate.

[0041] 2. This embodiment also provides the preparation method of the above-mentioned oil-soluble emulsion plugging agent, the specific steps are as follows:

[0042] 110 grams of deionized water, 3 grams of sodium methacrylate hydroxypropylsulfonate, and 0.02 grams of hydroxyethylethylenediaminetriacetic acid HEDTA were sequentially added to ...

Embodiment 2

[0049] 1. This embodiment provides an oil-soluble emulsion plugging agent, which is mainly prepared from various components in the following parts by mass:

[0050] 35 parts of butadiene monomer, 55 parts of styrene monomer, 18 parts of alkyl acrylate, 8 parts of glycidyl acrylate, 2 parts of octylphenol polyoxyethylene ether, 115 parts of deionized water, n-dodecyl 0.25 part of mercaptan, 0.03 part of antioxidant Irganox1098, 10 parts of white oil, 0.3 part of azobicyclohexylcarbonitrile, 0.015 part of hydroxyethylethylenediaminetriacetic acid (HEDTA), 0.3 part of p-tert-butylcatechol.

[0051] 2. This embodiment also provides the preparation method of the above-mentioned oil-soluble emulsion plugging agent, the specific steps are as follows:

[0052] 115 grams of deionized water, 2 grams of octylphenol polyoxyethylene ether, and 0.015 grams of HEDTA were sequentially added to a 1000 mL four-neck flask, and stirred at 240 rpm to form a solution. Remove the air under 0.09MPa ...

Embodiment 3

[0059] 1. This embodiment provides an oil-soluble emulsion plugging agent, which is mainly prepared from the following components in parts by mass:

[0060] 40 parts of butadiene monomer, 50 parts of styrene monomer, 25 parts of alkyl acrylate, 6.25 parts of glycidyl acrylate, 2.5 parts of sodium methacrylate hydroxypropyl sulfonate, 105 parts of deionized water, tert-dodecane 0.3 parts of base mercaptan, 0.025 parts of antioxidant Irganox1098, 7.5 parts of white oil, 0.4 parts of initiator, 0.02 parts of dihydroxyethylglycine, and 0.375 parts of p-tert-butylcatechol.

[0061] 2. This embodiment also provides the preparation method of the above-mentioned oil-soluble emulsion plugging agent, the specific steps are as follows:

[0062] 420 grams of deionized water, 10 grams of sodium methacrylate hydroxypropyl sulfonate, and 0.08 grams of dihydroxyethylglycine were sequentially added to a 4000 mL four-necked flask, and stirred at 350 rpm to form a solution. Remove the air under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com