A visible light responsive heterojunction composite material and a preparing method and use thereof

A composite material and visible light technology, which is applied in chemical instruments and methods, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of photocatalytic activity and visible light utilization efficiency, poor degradation performance, photogenerated Poor electron-hole separation efficiency and other issues, to achieve excellent photocatalytic activity, facilitate mass production, and high-efficiency photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

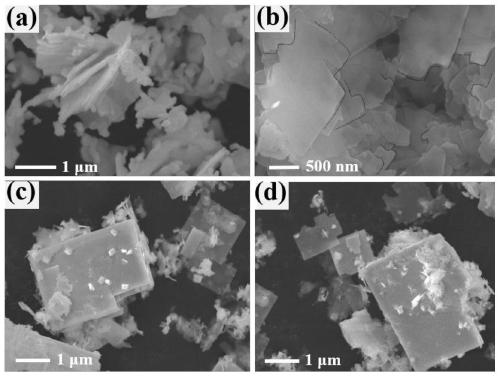

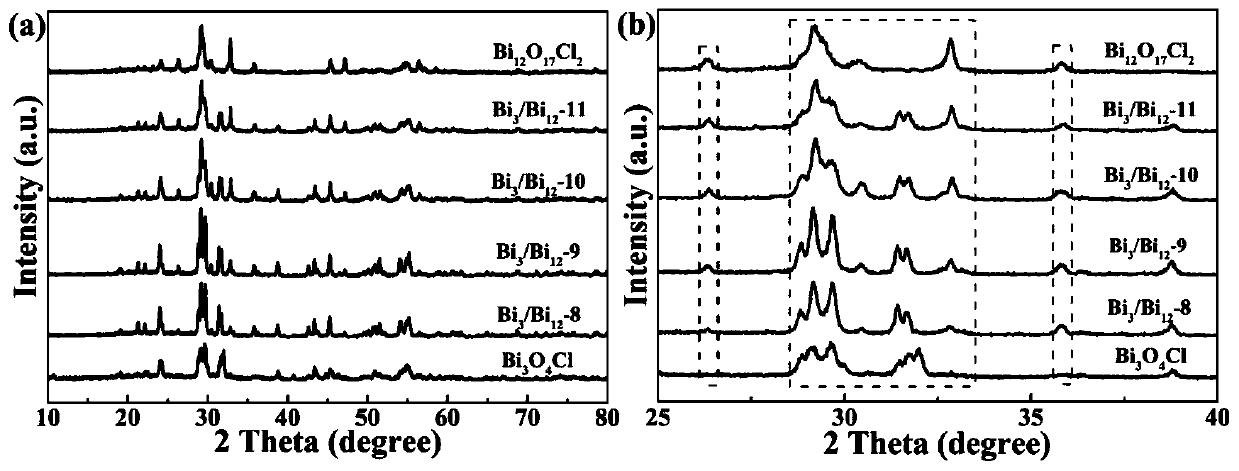

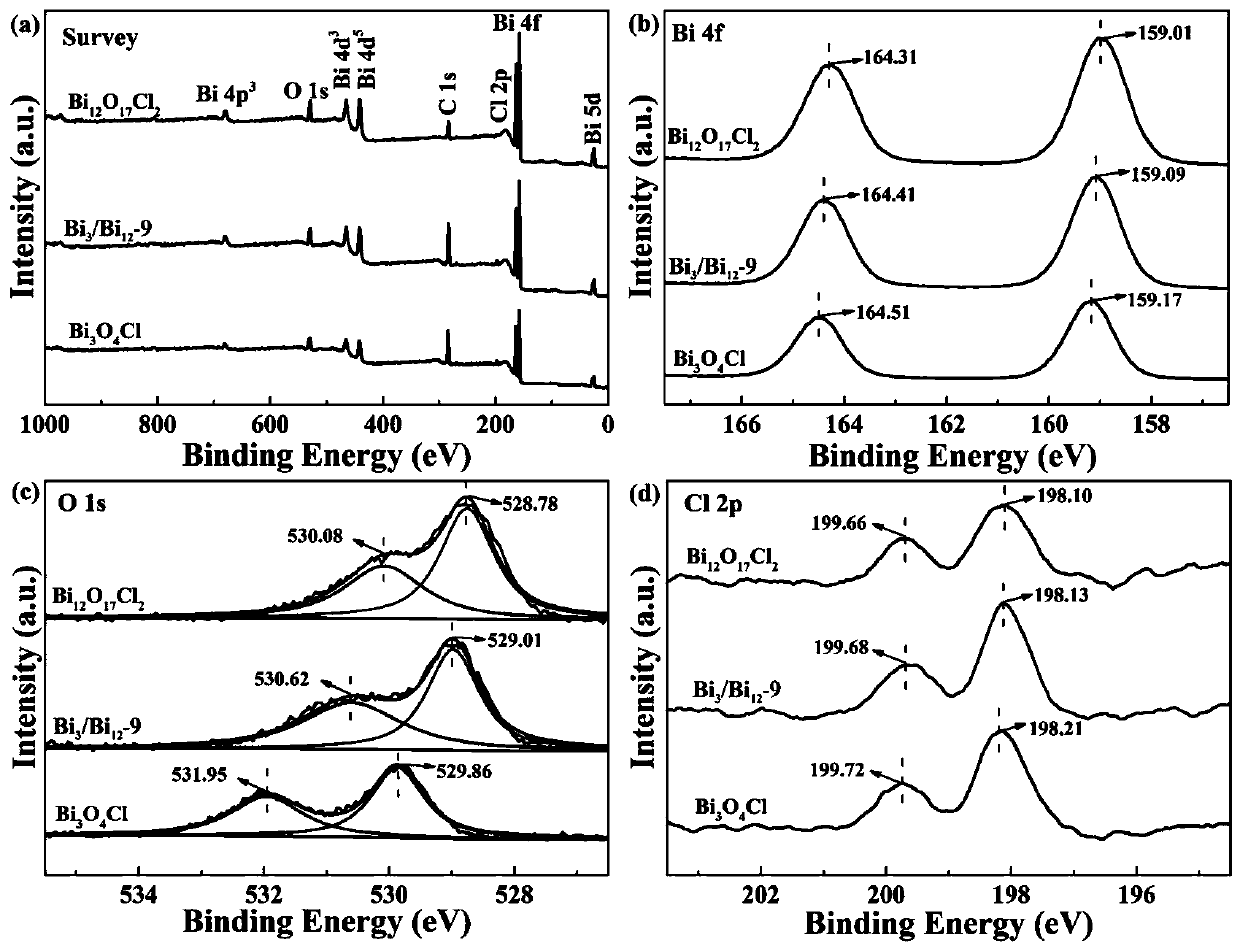

[0021] Step: Preparation of Bi 3 o 4 Cl nanosheets

[0022] First, 0.485g Bi(NO 3 ) 3 ·5H 2 O was ultrasonically dispersed in 10 mL of ethylene glycol for 10 min to obtain solution A. Next, add 0.018g NH 4 Dissolve Cl in 25mL deionized water to obtain solution B. Slowly add solution B to the above solution A to form a white turbid solution C, which is transferred to a 50mL reactor and heated at 160°C for 12h. After the reactor was cooled to room temperature, the sample was washed with water and ethanol, and dried at 60°C to obtain solid powder D. Finally, put the solid powder D in a muffle furnace, raise the temperature to 500°C at a rate of 5°C / min, and bake for 5h. Finally got Bi 3 o 4 Cl nanosheets.

Embodiment 2

[0024] Steps: One-step preparation of Bi 3 o 4 Cl / Bi 12 o 17 Cl 2 Heterojunction

[0025] First, 0.485g Bi(NO 3 ) 3 ·5H 2 O was ultrasonically dispersed in 10 mL of ethylene glycol and stirred for 10 min to obtain solution A. Next, add 0.018g NH 4 Cl was dissolved in 25mL deionized water to obtain solution B, and solution B was slowly added to the above solution A to generate white cloudy liquid C, and NaOH solution was slowly added dropwise to white cloudy liquid C to adjust pH=8 to obtain solution D, and the solution D was transferred into a 50mL reactor, and heated at 160°C for 12h. After the reactor was cooled to room temperature, the sample was washed with water and ethanol, and dried at 60°C to obtain solid powder E. Finally, put the solid powder E in a muffle furnace, raise the temperature to 500°C at a rate of 5°C / min, and bake for 5h. Finally got Bi 3 / Bi 12 -8 heterojunction materials.

Embodiment 3

[0027] Steps: One-step preparation of Bi 3 o 4 Cl / Bi 12 o 17 Cl 2 Heterojunction

[0028] First, 0.485g Bi(NO 3 ) 3 ·5H 2 O was ultrasonically dispersed in 10 mL of ethylene glycol and stirred for 10 min to obtain solution A. Next, add 0.018g NH 4 Cl was dissolved in 25mL deionized water to obtain solution B, and solution B was slowly added to the above solution A to generate white turbid liquid C, and NaOH solution was slowly added dropwise to white turbid liquid C to adjust pH=9 to obtain solution D, and the solution D was transferred into a 50mL reactor, and heated at 160°C for 12h. After the reactor was cooled to room temperature, the sample was washed with water and ethanol, and dried at 60°C to obtain solid powder E. Finally, put the solid powder E in a muffle furnace, raise the temperature to 500°C at a rate of 5°C / min, and bake for 5h. Finally got Bi 3 / Bi 12 -9 heterojunction materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com