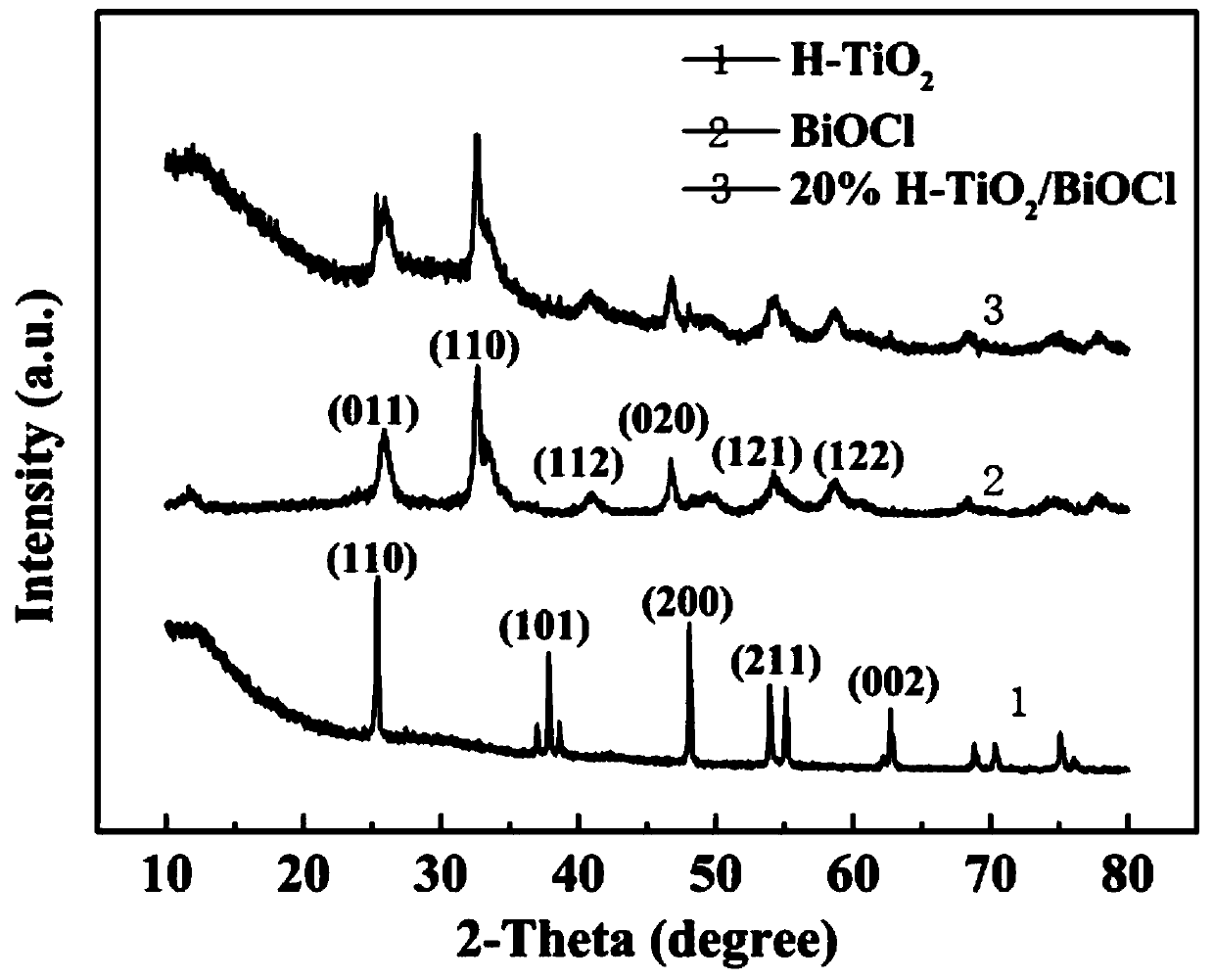

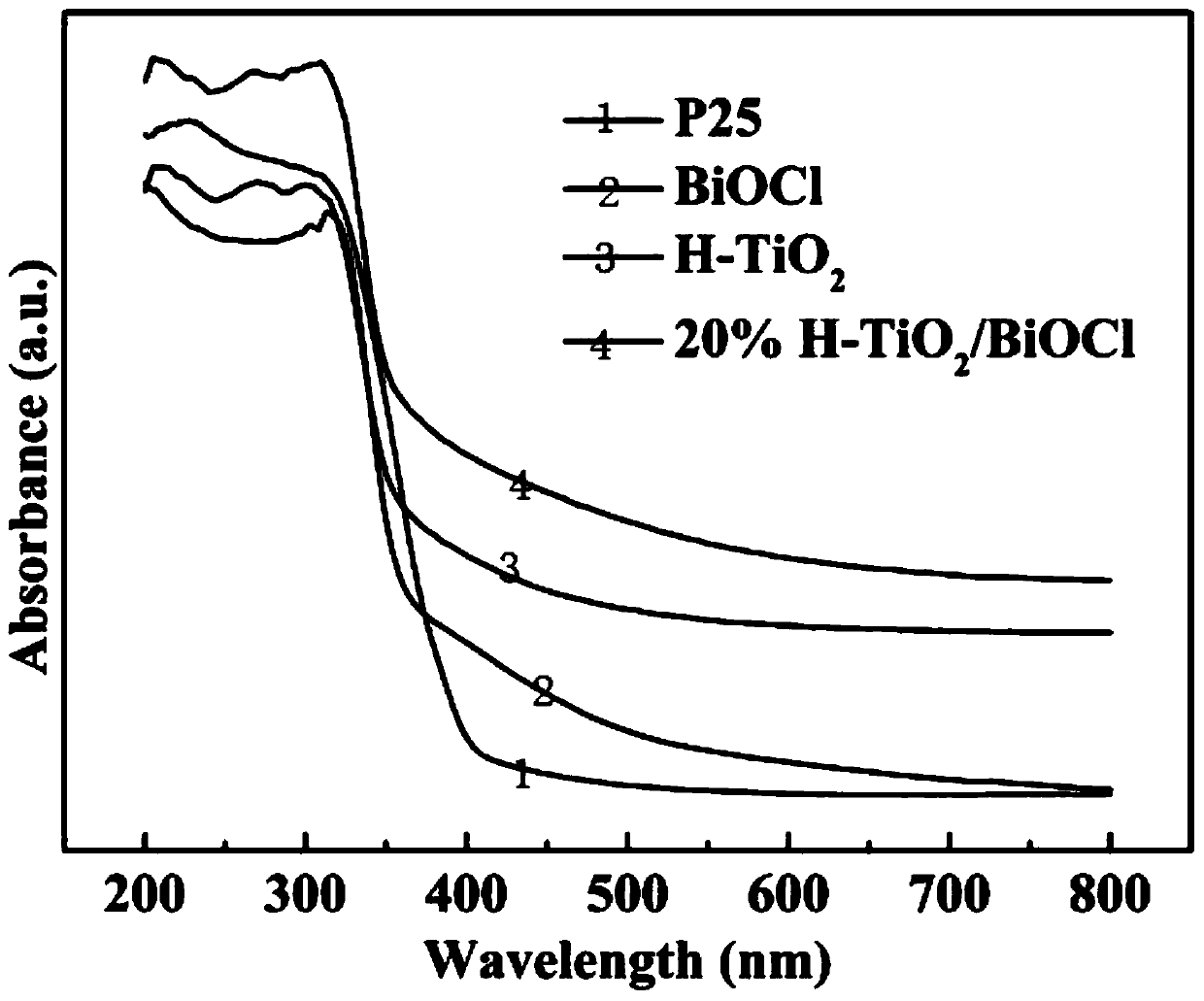

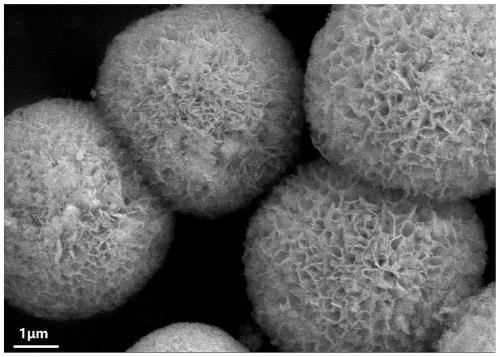

Hydrogenated titanium dioxide composite three-dimensional ballflower-shaped bismuth oxychloride photocatalyst and preparation method thereof

A technology of hydrogenated titanium dioxide and three-dimensional curds, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of green environmental protection treatment technology, easy operation and high-efficiency treatment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of hydrogenated titanium dioxide:

[0029] Mix 4 g of commercial P25 (titanium dioxide in mixed phase of anatase crystal and rutile crystal with an average particle size of 25 nm) and 1.5 g of sodium borohydride in a closed container, stir it magnetically to make it evenly mixed, and then transfer the mixture to a tube In the type furnace, hydrogen-argon mixed gas is used to protect the whole reaction process, and the heating rate is controlled to be 10°C per minute. After 3 hours at a high temperature of 300°C, the reactant turns black. After taking it out, it is washed three times with deionized water and ethanol to remove it. Sodium borohydride impurities, and then dried in an oven at 70°C to obtain hydrogenated titanium dioxide;

[0030] (2) Preparation of hydrogenated titanium dioxide composite three-dimensional curd bismuth oxychloride photocatalyst:

[0031] Take by weighing 2.426 grams of bismuth nitrate pentahydrate, add 15 milliliters of aceti...

Embodiment 2

[0034] (1) Preparation of hydrogenated titanium dioxide:

[0035] Mix 4 g of commercial P25 (titanium dioxide in mixed phase of anatase crystal and rutile crystal with an average particle size of 25 nm) and 1.5 g of sodium borohydride in a closed container, stir it magnetically to make it evenly mixed, and then transfer the mixture to a tube In the type furnace, hydrogen-argon mixed gas is used to protect the whole reaction process, and the heating rate is controlled at 10°C per minute. After 3 hours at 300°C, the reactant turns black. After taking it out, it is washed three times with deionized water and ethanol to remove it. Sodium borohydride impurities, and then dried in an oven at 70°C to obtain hydrogenated titanium dioxide;

[0036] (2) Preparation of hydrogenated titanium dioxide composite three-dimensional curd bismuth oxychloride photocatalyst:

[0037] Take by weighing 2.426 grams of bismuth nitrate pentahydrate, add 15 milliliters of acetic acid, make it mix unifo...

Embodiment 3

[0040] (1) Preparation of hydrogenated titanium dioxide:

[0041] Mix 4 g of commercial P25 (titanium dioxide in mixed phase of anatase crystal and rutile crystal with an average particle size of 25 nm) and 1.5 g of sodium borohydride in a closed container, stir it magnetically to make it evenly mixed, and then transfer the mixture to a tube In the type furnace, hydrogen-argon mixed gas is used to protect the whole reaction process, and the heating rate is controlled at 10°C per minute. After 3 hours at 300°C, the reactant turns black. After taking it out, it is washed three times with deionized water and ethanol to remove it. Sodium borohydride impurities, and then dried in an oven at 70°C to obtain hydrogenated titanium dioxide;

[0042](2) Preparation of hydrogenated titanium dioxide composite three-dimensional curd bismuth oxychloride photocatalyst:

[0043] Take by weighing 2.426 grams of bismuth nitrate pentahydrate, add 15 milliliters of acetic acid, make it mix unifor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com