Composite catalytic material, preparation method and application thereof in controllable preparation of dihydroxy/dimethylfuran compound

A technology of catalytic materials and polymers, applied in chemical instruments and methods, chemical/physical processes, organic compound/hydride/coordination complex catalysts, etc., can solve complex catalyst preparation process, numerous operation steps, complex composition, etc. Problems, to achieve good industrial application prospects, improve the effect of economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of above-mentioned catalytic material, comprises the steps:

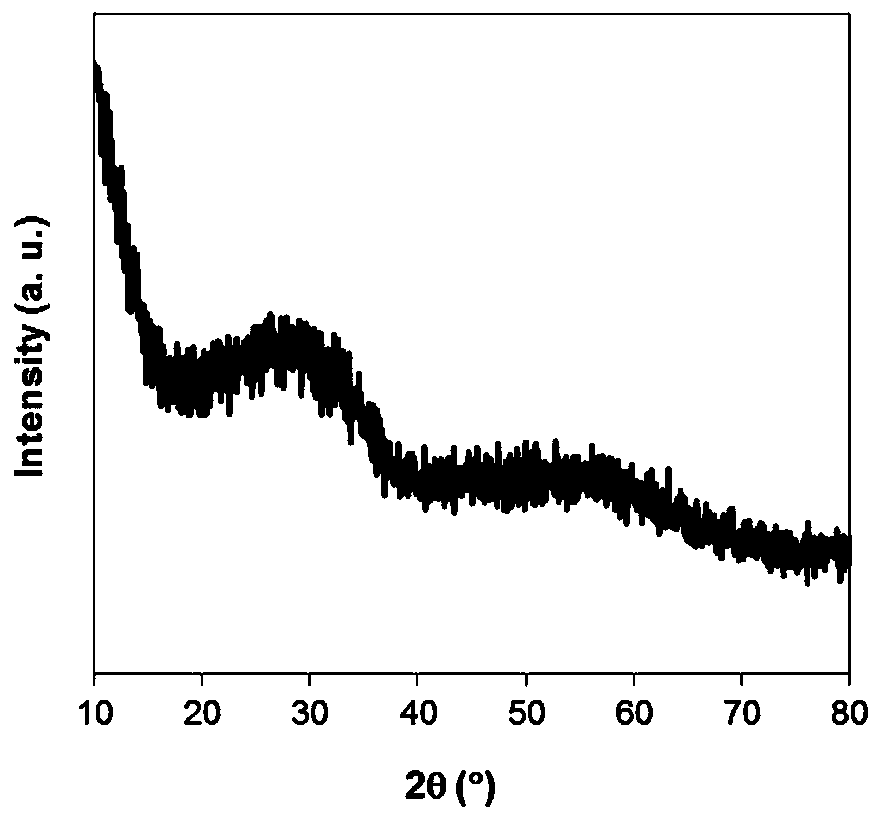

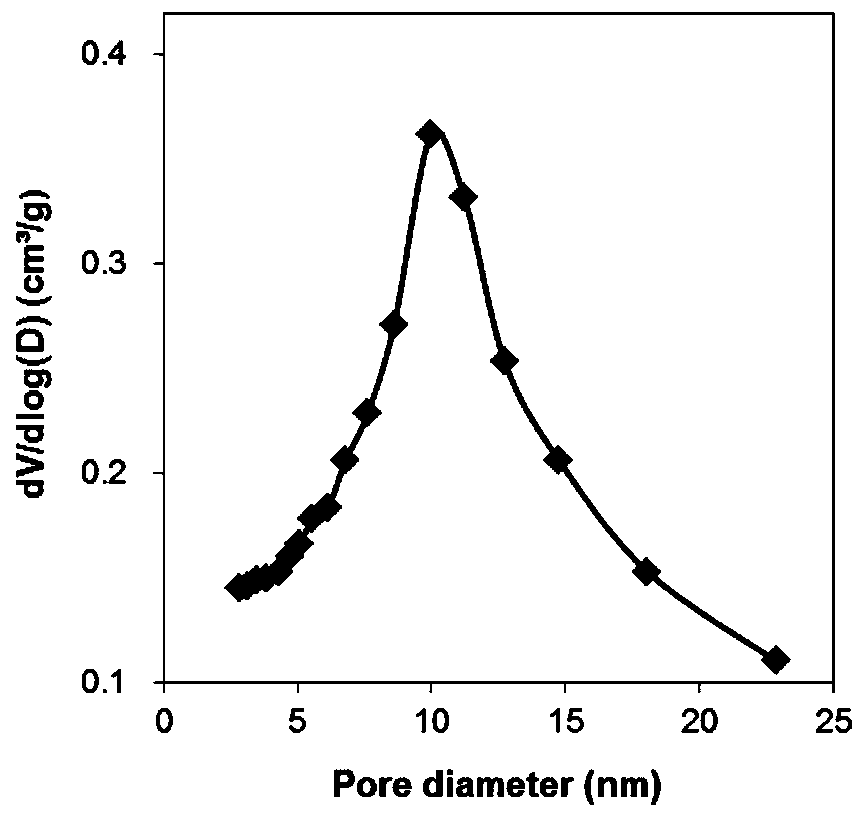

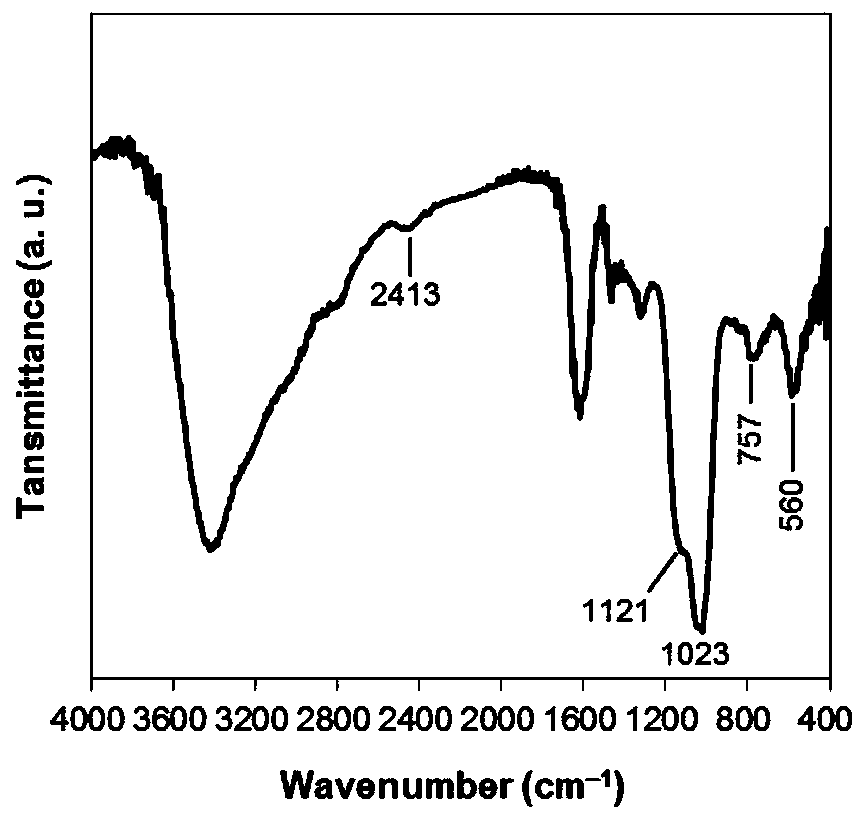

[0048] Preparation of the carrier: mixing the first metal chloride with an organic solvent to obtain a first mixed solution; mixing an organic phosphonic acid ligand with an organic solvent to obtain a second mixed solution; adding the first mixed solution to the second mixed solution , adding triethylamine, reacting, aging, washing, drying and pulverizing the generated precipitate to obtain an amorphous mesoporous metal phosphonic acid polymer carrier;

[0049] Active center loading: Disperse the amorphous mesoporous metal phosphonic acid polymer carrier in the solution containing the second metal chloride, then add NaBH 4 The aqueous solution is reacted, and the generated precipitate is washed, dried and pulverized to obtain an active metal-loaded amorphous mesoporous metal phosphonic acid polymer catalyst.

[0050] In one embodiment, the molar ratio of the first metal chloride, orga...

Embodiment 1

[0066] Add 10mmol of zirconium tetrachloride and 10mmol of biphenyl-4,4-diphosphonic acid ligand to 400mL of dimethylformamide solvent, stir well until completely dissolved; slowly add the zirconium tetrachloride solution to the organic phosphonic acid In the ligand solution, add 60 mmol of triethylamine dropwise to the above mixed solution, continue to stir for 4 hours at room temperature, raise the temperature to 80°C and let it stand for 4 hours; after the solid precipitate is separated by filtration, use dimethylformamide Repeated washing with ethanol until the presence of chloride ions is no longer detected; vacuum-dry the washed solid precipitate at 80°C for 12 hours, and grind it to about 200 mesh to obtain an amorphous mesoporous metal phosphonic acid polymer carrier; Take 1g of amorphous mesoporous metal phosphonic acid polymer carrier and disperse it in 300mL containing CuCl 2 In deionized water, ultrasonically stirred for 30 min and then continued to stir at room te...

Embodiment 2

[0070]Add 10mmol of hafnium tetrachloride and 10mmol of hydroxyethylidene diphosphonic acid ligand into 400mL of dimethylformamide solvent, stir well until completely dissolved; slowly add the hafnium tetrachloride solution into the organic phosphonic acid ligand solution , and then add 60mmol of triethylamine dropwise to the above mixed solution, continue to stir for 4h at room temperature, raise the temperature to 80°C and let it stand for 4h; after the solid precipitate is separated by filtration, it is washed repeatedly with dimethylformamide and ethanol Until the presence of chloride ions is no longer detected; vacuum-dry the washed solid precipitate at 80°C for 12 hours, and grind it to about 200 meshes to obtain an amorphous mesoporous metal phosphonic acid polymer carrier; take 1g of amorphous The mesoporous metal phosphonic acid polymer support was dispersed in 300mL containing CuCl according to the loading 2 In deionized water, ultrasonically stirred for 30 min and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com