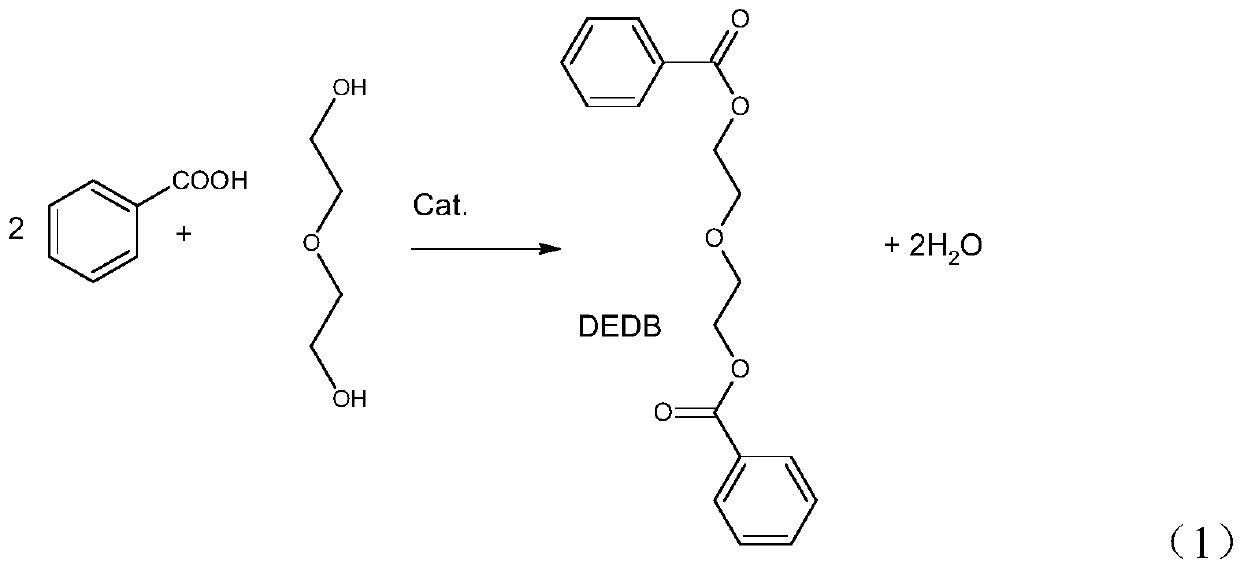

Method for producing environmentally friendly plasticizer diethylene glycol dibenzoate

A technology of diethylene glycol dibenzoate and an environmentally friendly plasticizer, which is applied in the preparation of carboxylate esters, chemical instruments and methods, and the separation/purification of carboxylic acid compounds, etc., and can solve the problem of unreachable and greatly affected by water content , long reaction time and other issues, to achieve the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

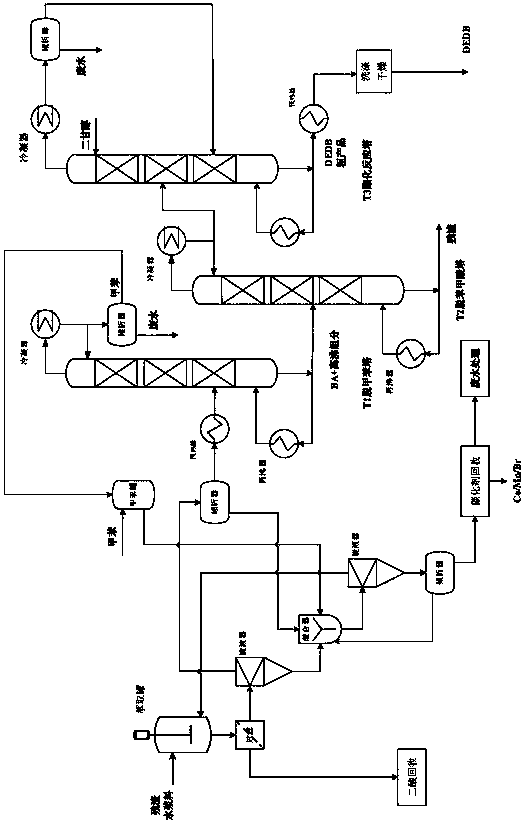

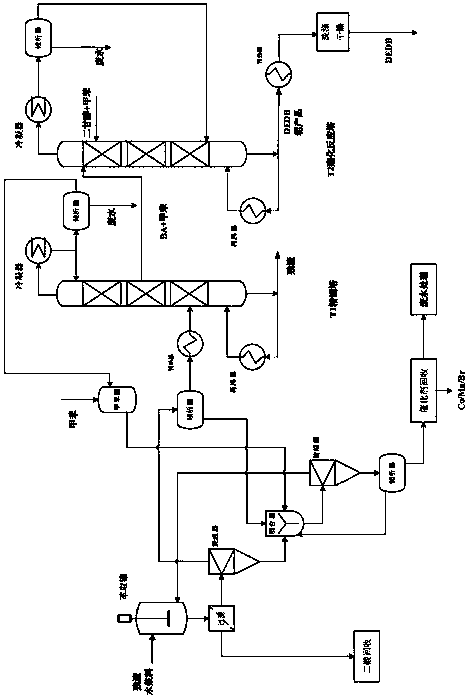

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment is the laboratory experiment of esterification of benzoic acid and diethylene glycol. Put 96.0 g of benzoic acid, 39.72 g of diethylene glycol, 17.28 g of toluene and two zeolites into a three-necked flask, and heat slowly. Heat to about 120°C. After the benzoic acid is basically dissolved, add 1.0 g of tetrabutyl titanate as a catalyst, start stirring and condensing, and carry out esterification under heating and reflux. When the first drop of water was formed, the reaction start time was recorded. When the temperature reached 180°C, the toluene began to reflux to separate the water. The toluene was refluxed into the three-necked flask, and the water generated by the reaction was released in batches. Reflux and dehydrate at about 180°C for about 5 hours. When no water is separated, the esterification is complete, and then cool down to room temperature. Wash the above-mentioned materials with alkaline water, then stand still, separate the liquid,...

Embodiment 2

[0039] This example is similar to Example 1, except that the temperature is changed to 200° C. for the esterification reaction, and the remaining steps and amounts are the same.

[0040] The yield of diethylene glycol dibenzoate product is 35.2 wt%. Due to the high temperature, a large amount of toluene is evaporated, and the reflux of condensation is not enough, so that the water produced by the esterification reaction cannot be taken out of the reaction system in time, so that the conversion rate is not high.

Embodiment 3

[0042] This example is similar to Example 1, except that the amount of the catalyst is changed to 0.5 wt% of the total mass of the reactants, and the other steps and amounts are the same.

[0043] The yield of the diethylene glycol dibenzoate product determined by high performance liquid chromatography was 90.1 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com