Ultra-crosslinking organic polymer material and preparation method and application of ultra-crosslinking organic polymer material

A super-crosslinked, microporous polymer technology, applied in the field of materials, can solve the problems of high temperature resistance, deformity and cancer, and a greater threat to human health, and achieves simple and convenient operation and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

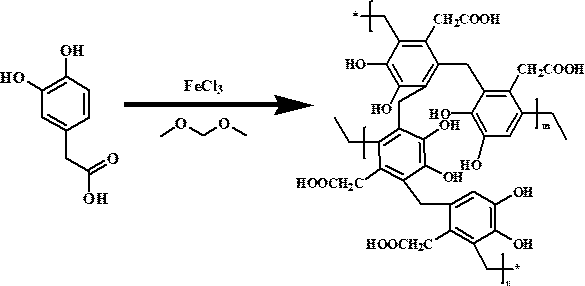

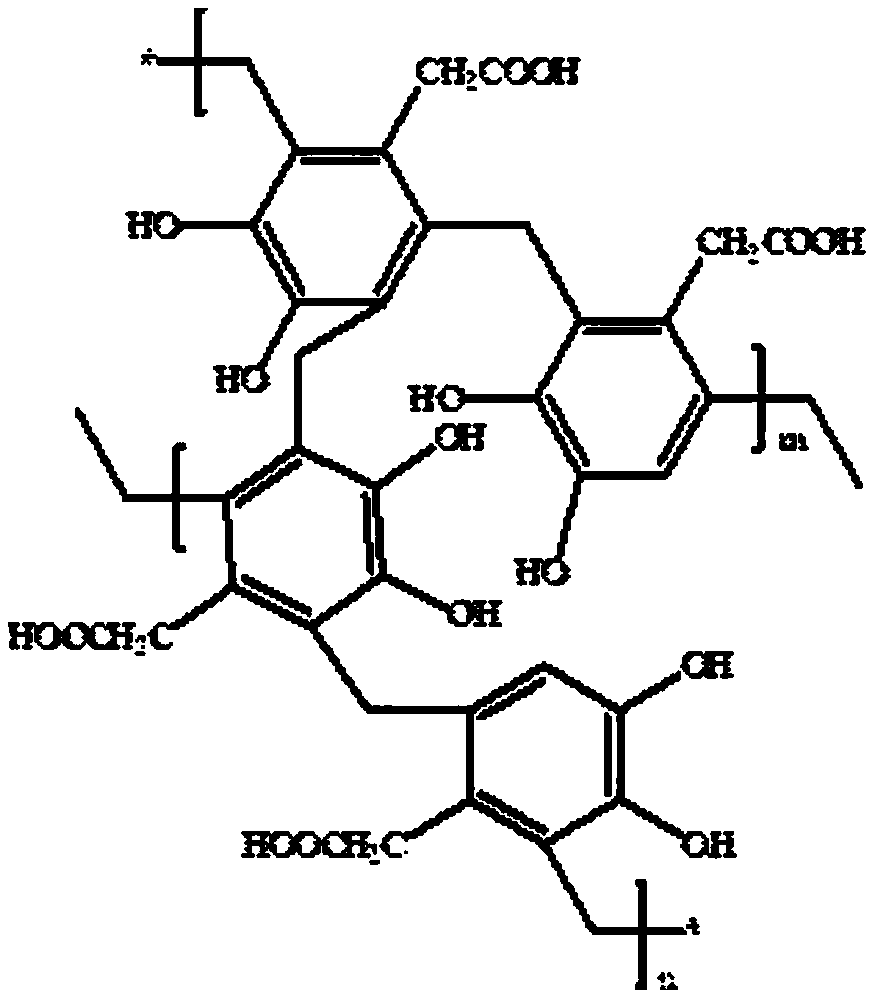

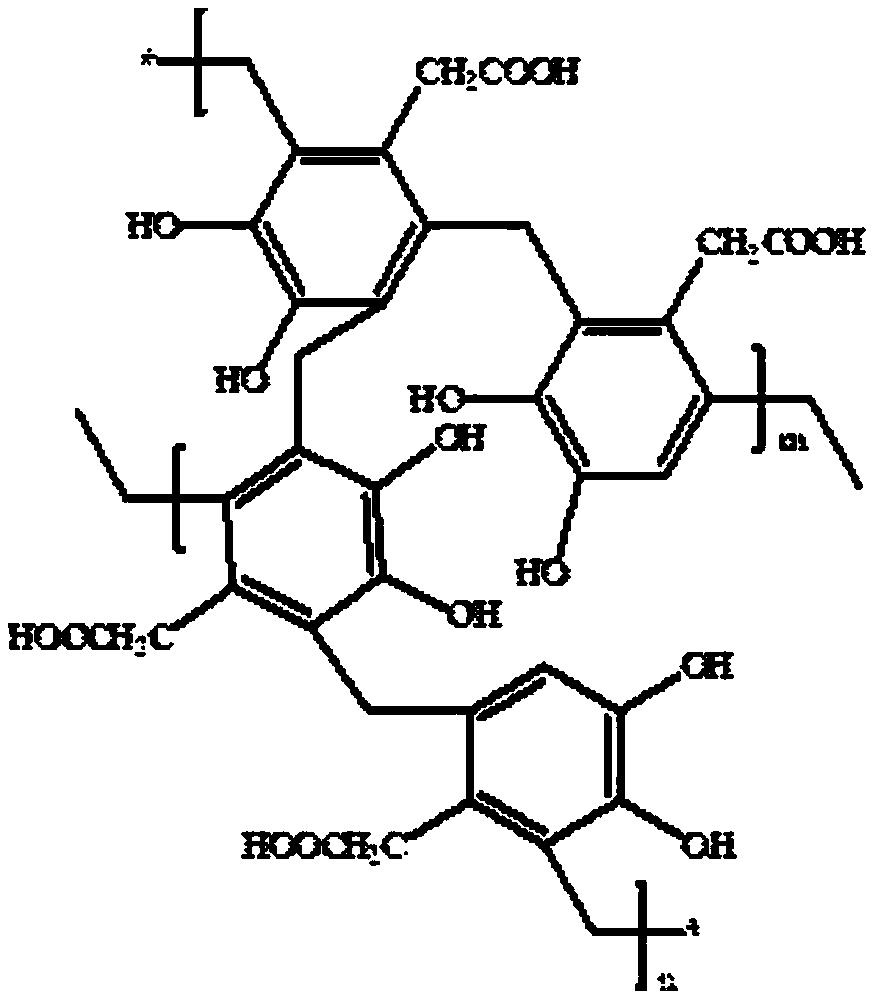

[0021]Preparation of hypercrosslinked organic microporous polymers (HCPs): Weigh a certain amount of 1 g of 3,4-dihydroxyphenylacetic acid and dissolve it in 5 mL of methanol, and add 20 mL of 1,2-dichloroethane to the solution 0.04 mol of cross-linking agent dimethoxymethane was added under the protection of nitrogen, and 0.04 mol of anhydrous ferric chloride was added under stirring under the protection of nitrogen, the reaction was refluxed at 45 ℃ for 5 h, and refluxed at 80 ℃ for 6 h. After the reaction was completed, the product was transferred to an Erlenmeyer flask, washed several times with methanol, and extracted by Soxhlet until the supernatant was colorless. Dry in vacuum at 60 °C for 24 h.

[0022] Evaluation of Adsorption and Separation Capabilities

[0023] Weigh 100 mg of HCPs and disperse in methanol, fill in the pipeline, and use 5 mL of methanol at a flow rate of 0.3 mL·min -1 Eliminate air bubbles in the pipeline, at 0.1 mL·min -1 Inject 3 mL of simulate...

Embodiment 2

[0026] Preparation of hypercrosslinked organic microporous polymers (HCPs): Weigh a certain amount of 1 g of 3,4-dihydroxyphenylacetic acid and dissolve it in 6 mL of methanol, and add 30 mL of 1,2-dichloroethane to the solution 0.05 mol of cross-linking agent dimethoxymethane was added under the protection of nitrogen, and 0.05 mol of anhydrous ferric chloride was added under stirring under the protection of nitrogen, the reaction was refluxed at 45 ℃ for 5 h, and refluxed at 80 ℃ for 9 h. After the reaction was completed, the product was transferred to an Erlenmeyer flask, washed several times with methanol, and extracted by Soxhlet until the supernatant was colorless. Dry in vacuum at 60 °C for 24 h.

[0027] Evaluate the effect of adsorption and separation

[0028] Weigh 105 mg of HCPs and disperse in methanol, fill in the pipeline, and use 6 mL of methanol at a flow rate of 0.5 mL·min -1 Eliminate air bubbles in the pipeline, at 0.2 mL·min -1 Inject 4 mL of simulated s...

Embodiment 3

[0031] Preparation of hypercrosslinked organic microporous polymers (HCPs): Weigh a certain amount of 1 g of 3,4-dihydroxyphenylacetic acid and dissolve it in 7 mL of methanol, and add 40 mL of 1,2-dichloroethane to the solution 0.06 mol of cross-linking agent dimethoxymethane was added under the protection of nitrogen, and 0.06 mol of anhydrous ferric chloride was added under stirring under the protection of nitrogen, the reaction was refluxed at 45 ℃ for 5 h, and refluxed at 80 ℃ for 12 h. After the reaction was completed, the product was transferred to an Erlenmeyer flask, washed several times with methanol, and extracted by Soxhlet until the supernatant was colorless. Dry in vacuum at 60 °C for 24 h.

[0032] Evaluate the effect of adsorption and separation

[0033] Weigh 110 mg of HCPs and disperse in methanol, fill in the pipeline, and use 7 mL of methanol at a flow rate of 0.3 mL·min -1 Eliminate air bubbles in the pipeline, at 0.1 mL·min -1 Inject 5 mL of simulated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com