Lithium ion battery cathode aqueous adhesive as well as preparation method and cathode material thereof

A lithium-ion battery, water-based binder technology, used in battery electrodes, secondary batteries, adhesive types, etc. Good adhesion and the effect of improving adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

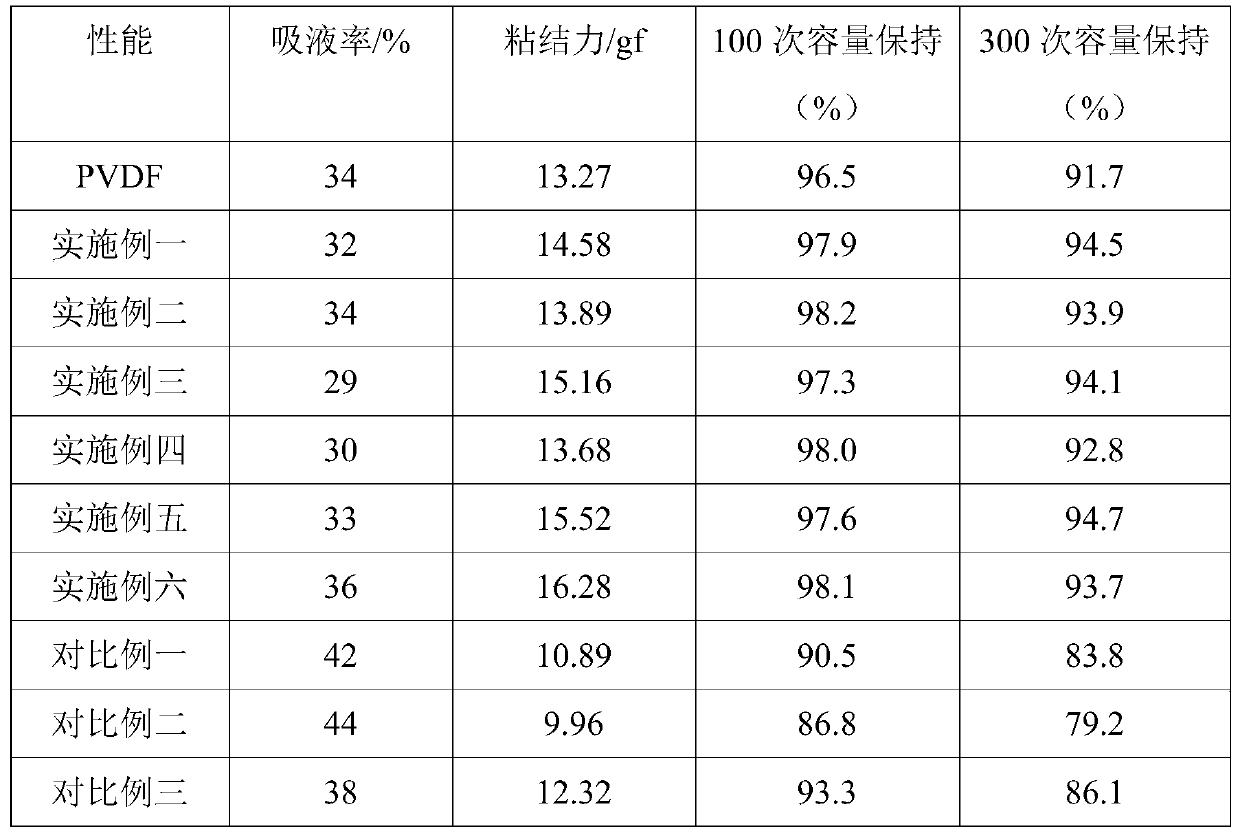

Examples

Embodiment 1

[0048] The concrete steps of synthesizing lithium-ion battery negative electrode water-based binder are as follows:

[0049] (1) Add 386g of deionized water, 68g of methyl acrylate, 150g of isooctyl acrylate, 60g of hydroxypropyl methacrylate, 10g of maleic acid and 8.2g of AES into a 1000mL flask, and stir for 30min to obtain a pre-emulsion.

[0050] (2) Dissolve 0.75g of ammonium persulfate in 60g of water to obtain an initiator solution, and dissolve 2.07g of LiOH in 25g of water to obtain a lye.

[0051] (3) Add 240g of water and 0.82g of diallyl phthalate into a 2000mL flask equipped with a nitrogen device, a condenser, a stirrer, a thermometer and a peristaltic pump, and feed a large amount of nitrogen to raise the temperature until the temperature rises to 83°C. Then add the pre-emulsion and initiator solution dropwise at a constant temperature at 85±1°C for 3 hours. After the dropping is completed, keep warm for 1 hour, and then add residual additives three times with ...

Embodiment 2

[0054] The concrete steps of synthesizing lithium-ion battery negative electrode water-based binder are as follows:

[0055] (1) In a 1000mL flask, add 386g deionized water, 44g methyl methacrylate, 106g n-butyl methacrylate, 98g butyl acrylate, 48g isooctyl methacrylate, 52g cyclohexyl methacrylate, 30g of acrylic acid and 9.45g of AES were stirred for 30min to obtain a pre-emulsion.

[0056] (2) Dissolve 0.75g of potassium persulfate in 60g of water to obtain an initiator solution, and dissolve 4.28g of NaOH in 25g of water to obtain a lye.

[0057] (3) Add 240g of water and 0.82g of diallyl phthalate into a 2000mL flask equipped with a nitrogen device, a condenser, a stirrer, a thermometer and a peristaltic pump, and feed a large amount of nitrogen to raise the temperature until the temperature rises to 83°C. Then add the pre-emulsion and initiator solution dropwise at a constant temperature at 85±1°C for 3 hours. After the dropping is completed, keep warm for 1 hour, and ...

Embodiment 3

[0060] The concrete steps of synthesizing lithium-ion battery negative electrode water-based binder are as follows:

[0061] (1) Add 386g deionized water, 75g ethyl methacrylate, 45g vinyl acetate, 110g ethyl acrylate, 40g dodecyl methacrylate, 90g tetrahydrofuryl methacrylate, 20g formazan to a 1000mL flask Acrylic acid and 5g of AES were stirred for 30min to obtain a pre-emulsion.

[0062] (2) Dissolve 1 g of ammonium persulfate in 60 g of water to obtain an initiator solution, and dissolve 4.55 g of KOH in 25 g of deionized water to obtain a lye.

[0063] (3) Add 240g of water and 1.96g of aminotrimethylene phosphonic acid into a 2000mL flask equipped with a nitrogen device, condenser, stirrer, thermometer and peristaltic pump, feed a large amount of nitrogen to raise the temperature, wait until the temperature rises to 83°C, and then Add the pre-emulsion and initiator solution dropwise, keep the temperature at 85±1°C, and last for 3 hours. After the dropwise addition, kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com