Light guide plate and preparation method thereof

A light guide plate and light guide point technology, which is applied in the field of light guide plates, can solve problems such as uneven thickness distribution of light guide plates, inability to uniform light and light transmission, and poor light transmission performance, and achieve excellent colorless transparency and solve uniformity. The effect of improving light and light transmission and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

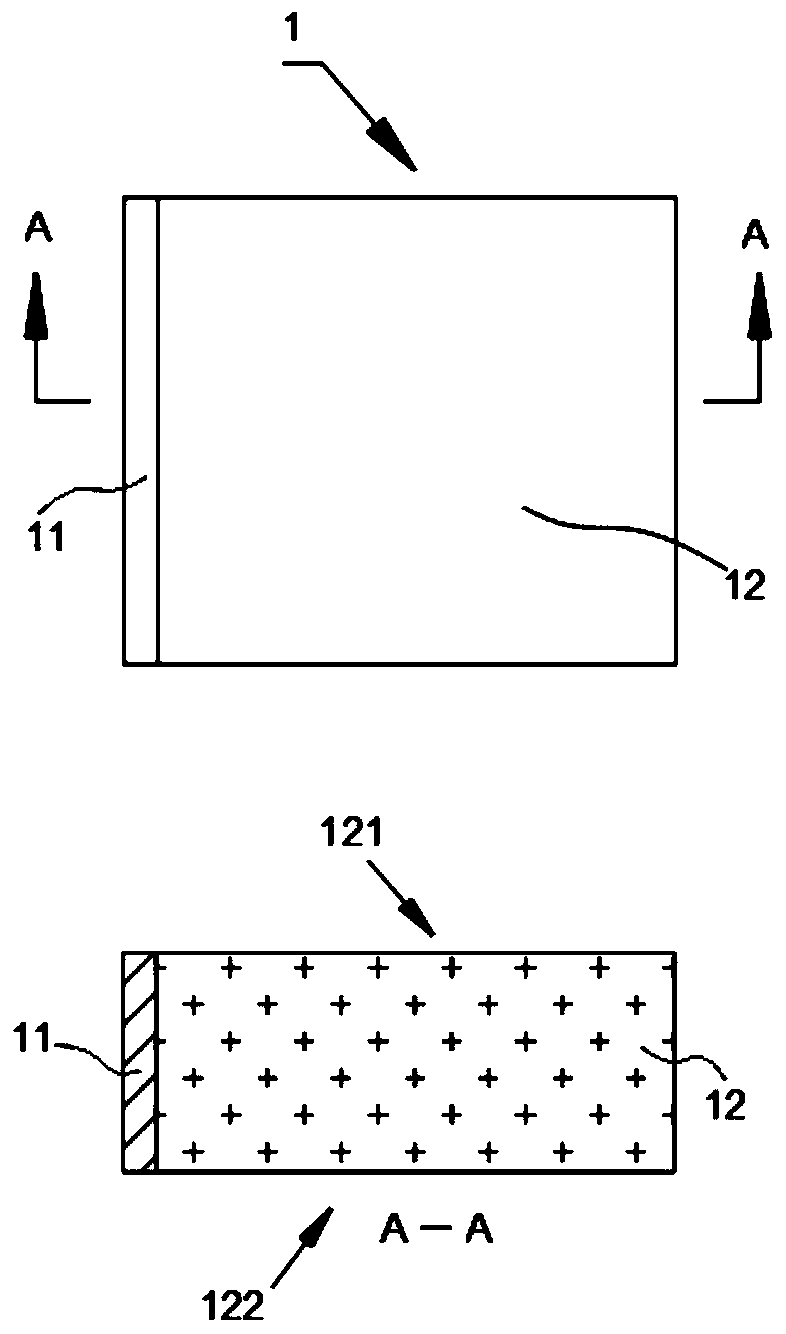

[0043] A light guide plate, the light guide plate 1 includes a light exit surface 122, a back surface 121 and several sides, the light exit surface 122 is set opposite to the back surface 121, the back surface 121 is provided with a light guide point, and the side surfaces are connected to the light exit surface 122 and The back side 121, wherein at least one side is provided with a light entering layer (11), the part 12 of the light guide plate other than the light entering layer 11 is a PS layer, and the light entering layer material is composed of the following components in parts by weight: poly 25 parts of methyl acrylate, 2 parts of microporous hydroxyapatite, 10 parts of n-propyl silicate, 6 parts of cellulose triacetate, 25 parts of acrylonitrile-butadiene-styrene copolymer, 10 parts of ultrafine active silica powder 4 parts, 4 parts of dimethyl silicone oil, 8-11 parts of polymethylpentene resin, 10 parts of polytetrafluoroethylene, 8 parts of octylphenol, 6-13 parts o...

Embodiment 2

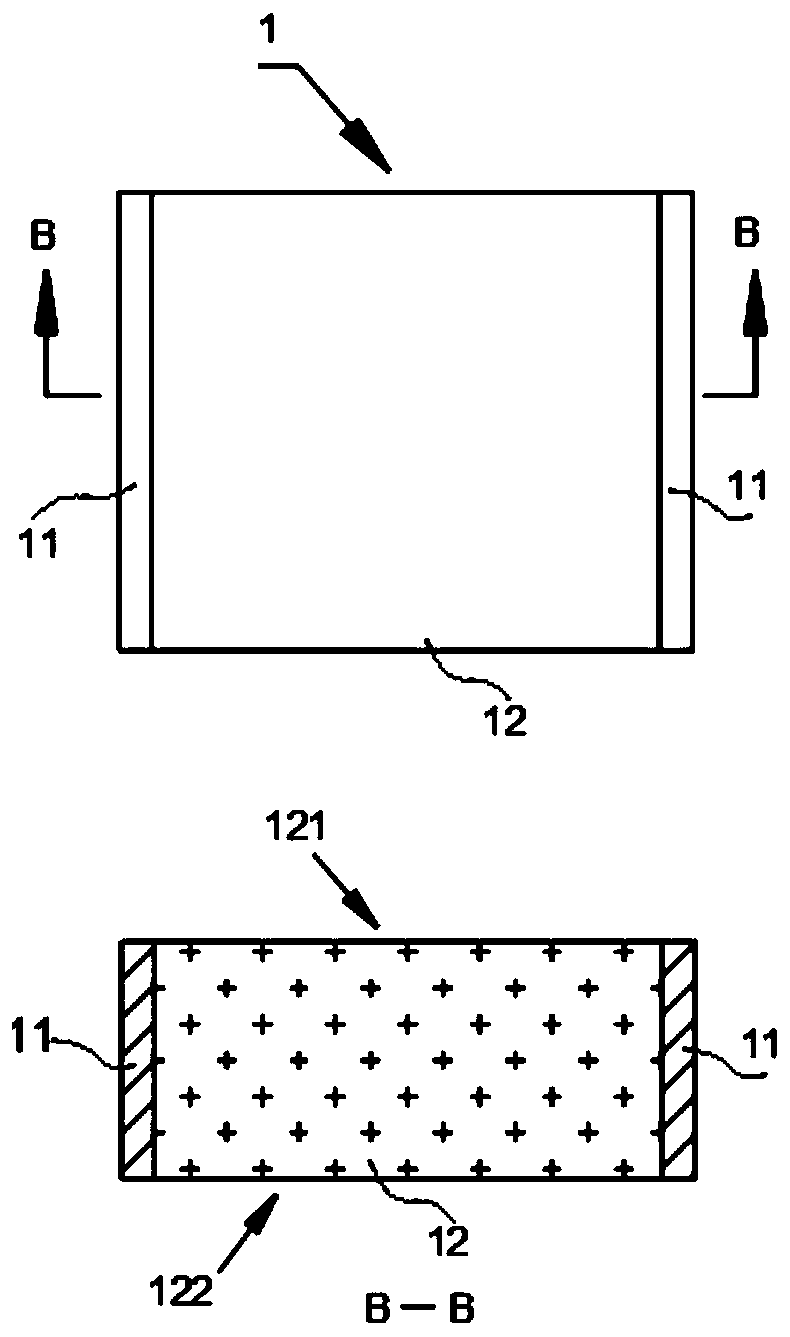

[0051] A light guide plate, the light guide plate 1 includes a light exit surface 122, a back surface 121 and several sides, the light exit surface 122 is set opposite to the back surface 121, the back surface 121 is provided with a light guide point, and the side surfaces are connected to the light exit surface 122 and The back side 121, wherein at least one side is provided with a light-introduction layer 11, the part 12 of the light guide plate other than the light-introduction layer 11 is a PS layer, and the material of the light-introduction layer is composed of the following components in parts by weight: polymethyl acrylate 28 parts of ester, 5 parts of microporous hydroxyapatite, 12 parts of n-propyl silicate, 10 parts of cellulose triacetate, 30 parts of acrylonitrile-butadiene-styrene copolymer, 11 parts of ultrafine active silica powder, 4 parts of dimethyl silicone oil, 9 parts of polymethylpentene resin, 11 parts of polytetrafluoroethylene, 12 parts of octylphenol,...

Embodiment 3

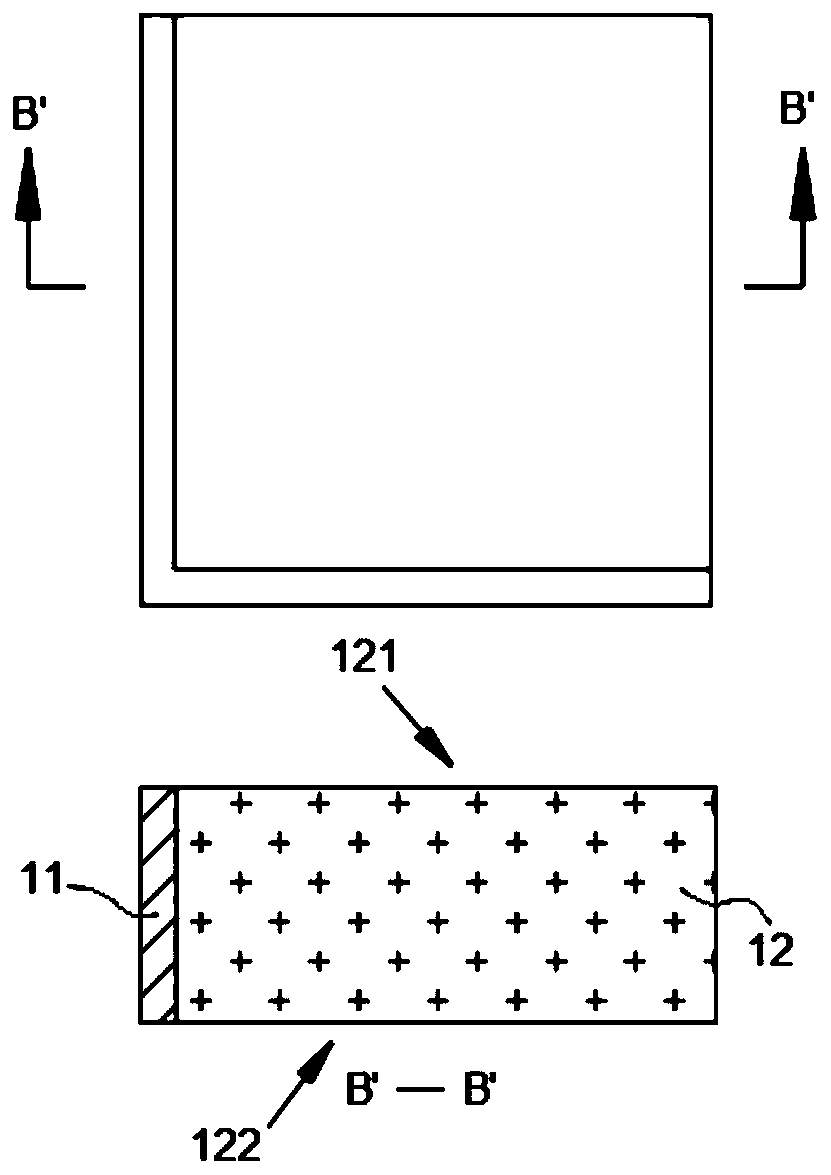

[0059] Using the materials of Example 2, the structure of the prepared light guide plate device is basically the same as that of Example 1, the difference is that the light guide plate 1 is a rectangular plate, and the two sides of the rectangular plate are provided with light-incoming layers 11; the two sides are opposite sides, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com