Method for adjusting surface energy level and energy band of semiconductor material

A surface energy level and semiconductor technology, which is applied in the manufacture of semiconductor/solid-state devices, discharge tubes, electrical components, etc., can solve the problems of inconsistency in characteristic parameters and weak regulation, and achieve reduced energy consumption, low energy consumption, and no macroscopic The effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for regulating the surface energy level of an FTO semiconductor material, comprising the following steps:

[0028] Step 1. Select the fluorine-doped tin oxide semiconductor (FTO) material on the glass substrate, place it in acetone, absolute ethanol and water for ultrasonic cleaning, each time for 10 minutes, and dry it for later use after ultrasonic;

[0029] Step 2. Place the glass substrate with FTO semiconductor material cleaned in step 1 on the metal lower plate in the chamber of the plasma processing instrument. The distance between the two metal plates is 34mm, and the upper plate is connected to a 27MHz radio frequency Power supply, the lower plate is connected to a 13.56MHz radio frequency power supply, wherein the plate spacing can change the position of the plasma sheath, so that the surface of the FTO is in the plasma sheath, the upper plate generates plasma, and the lower plate provides additional bias for the plasma, so that increased plasma bomba...

Embodiment 2

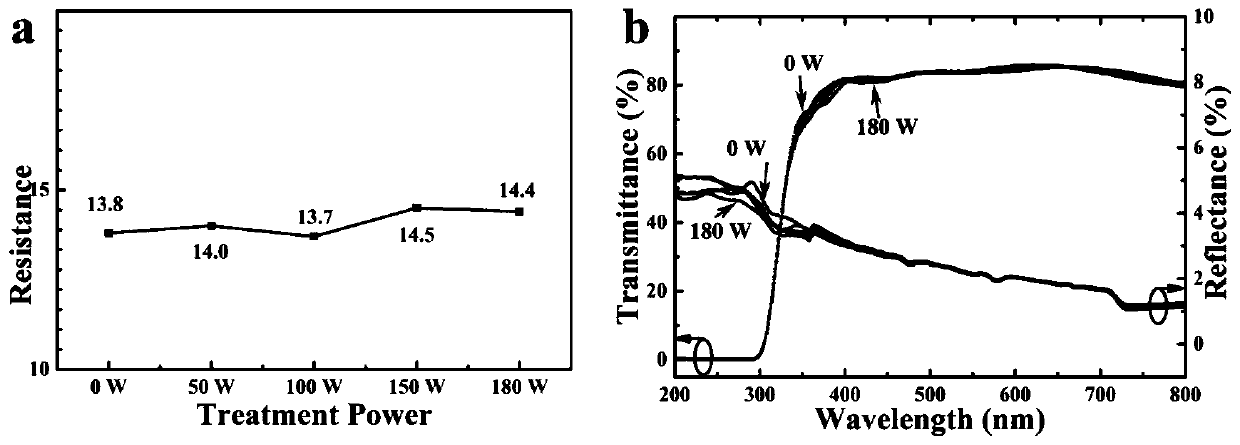

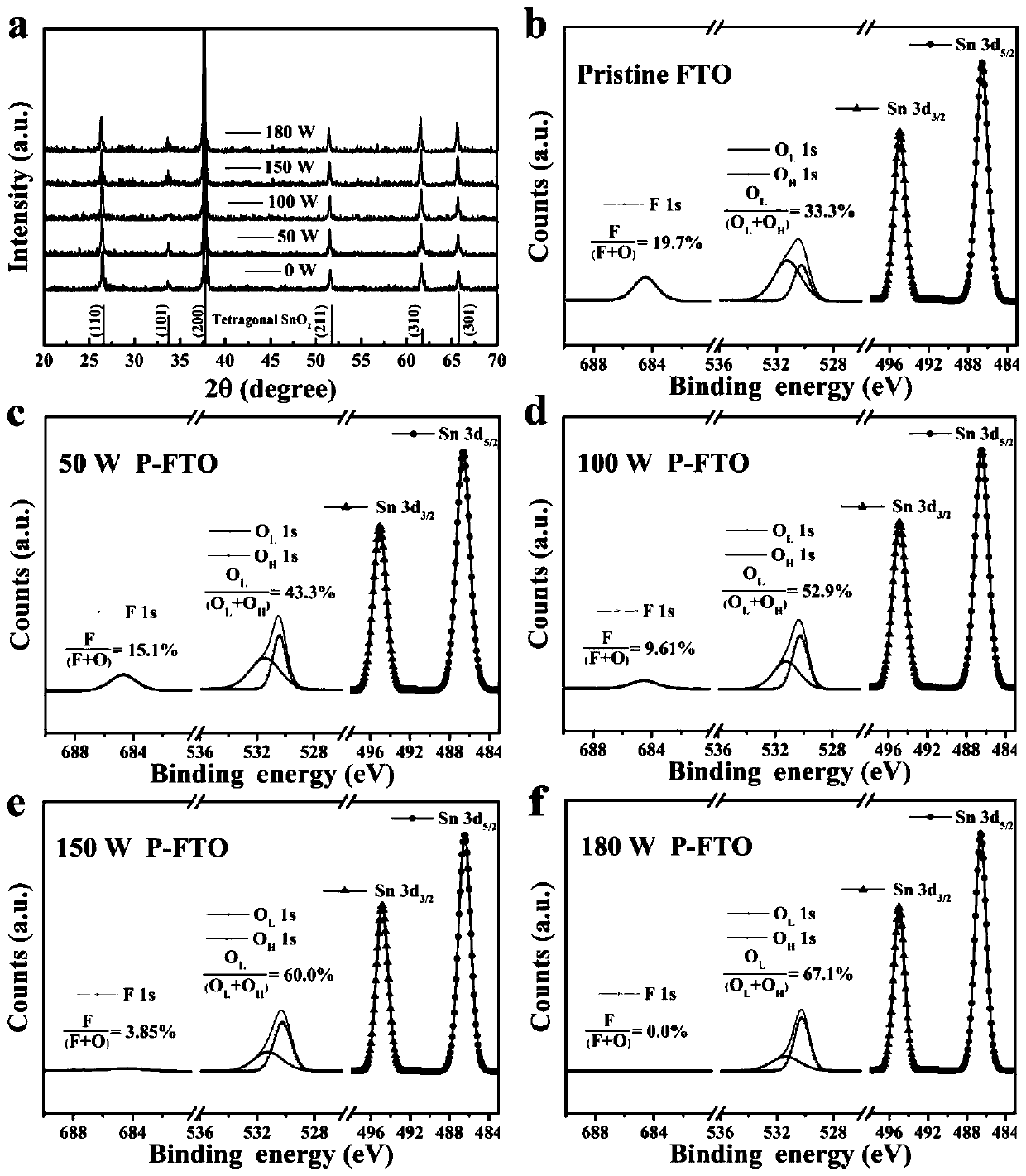

[0035] Process the FTO according to the steps in Example 1, only adjust the discharge power of the upper plate in step 4 to 50W, 100W, 180W, and keep other steps unchanged. The resistive light transmission and reflection of the processed FTO obtained in this embodiment are as follows: figure 2 Shown; X-ray diffraction pattern (XRD) spectrum and X-ray photoelectron spectrum (XPS) are as image 3 shown.

Embodiment 3

[0037] A method for regulating the surface energy level of an FTO semiconductor material, comprising the following steps:

[0038] Step 1. Select the fluorine-doped tin oxide semiconductor material on the glass substrate, place it in acetone, absolute ethanol and water for ultrasonic cleaning, each time for 10 minutes, and dry it for later use after ultrasonic;

[0039] Step 2. Place the glass substrate with FTO semiconductor material cleaned in step 1 on the metal lower plate in the chamber of the plasma processing instrument. The distance between the two metal plates is 34mm, and the upper plate is connected to a 27MHz radio frequency Power supply, the lower plate is connected to a 13.56MHz RF power supply;

[0040] Step 3. Vacuumize the chamber of the plasma processor to keep the background vacuum degree less than 10 -3 Pa; then fill the vacuum chamber with argon with a purity of 99.999% and O with a purity of 99.99% 3, the flow rate ratio of argon and ozone is 3:1, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com