Photo-cured solid state composite electrolyte and preparation method thereof

A technology of composite electrolyte and solid electrolyte, which is applied in the field of light-cured solid composite electrolyte and its preparation, can solve the problems of reducing impedance and low Coulombic efficiency, and achieve the effects of reducing interface impedance, easy availability of raw materials, and high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

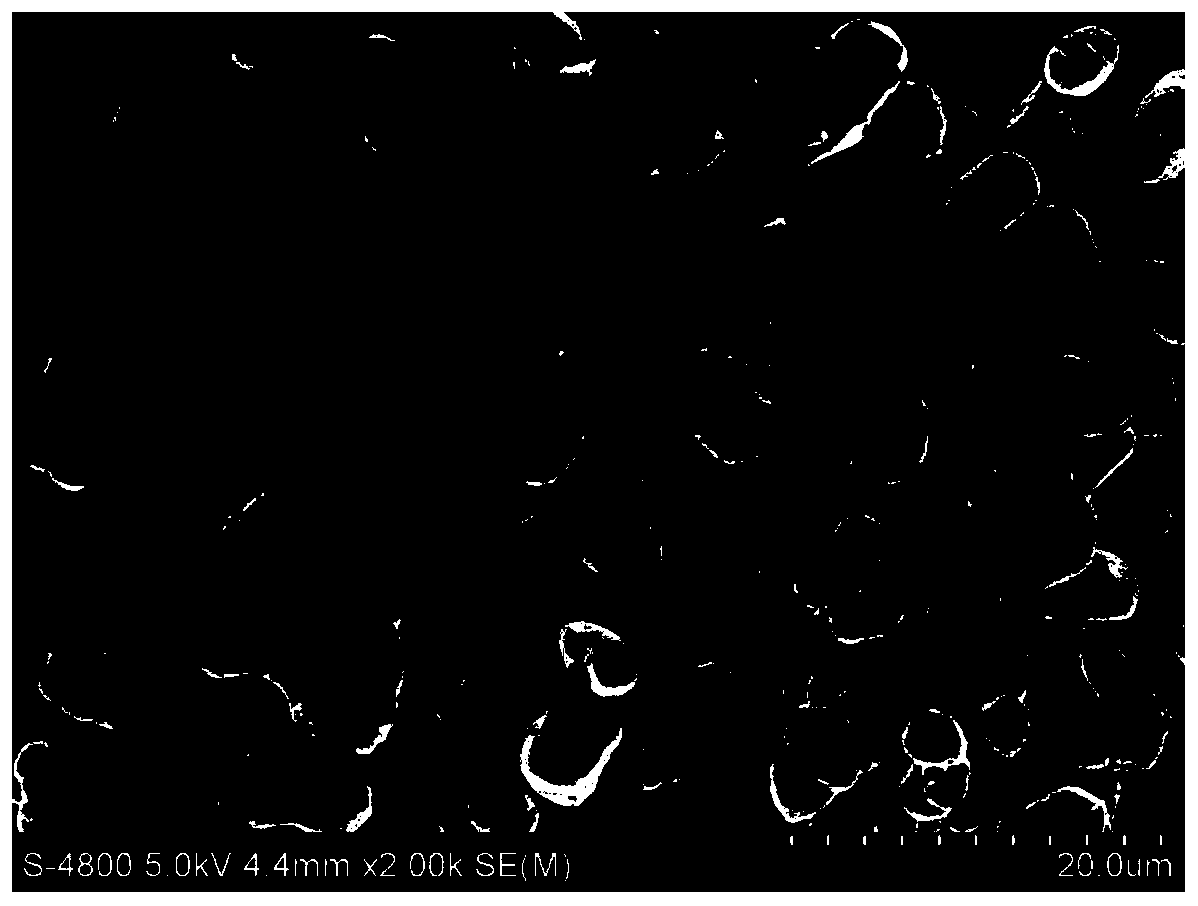

[0050] (1) In a glove box filled with argon (H 2 O2 13 ]-[TFSI], continue to stir in the dark for 8 hours, and finally add 10 g of Li with a particle size of 5 μm to 8 μm 6.4 La 3 Zr 1.4 Ta 0.6 o 12 ,like figure 1 As indicated, continue to stir in the dark for 3 h at a speed of 500 r / min, and finally obtain a homogeneous mixture.

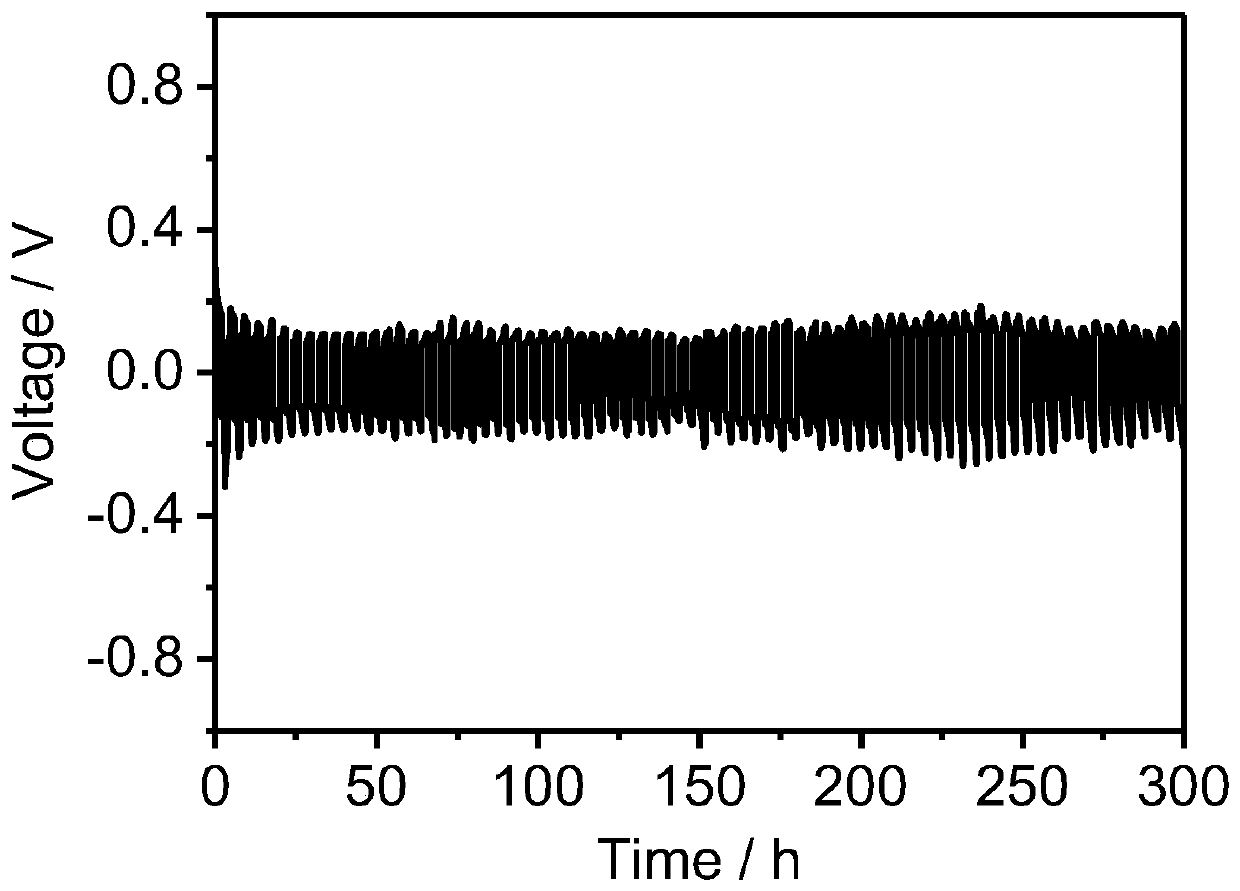

[0051] (2) In a glove box filled with argon (H 2 O2 figure 2 As shown, the electrolyte is away from the side of the flat plate, the surface is smooth, the content of inorganic solid electrolyte is small, and the polymer content is large. As the side close to the metal negative electrode, the compatibility between the electrolyte and the alkali metal negative electrode can be effectively improved, and the interface impedance can be reduced; the other side The high content of inorganic solid electrolyte is close to the positive electrode side, which can solve the disadvantage that PEO is easily oxidized when it is directly in contact with the p...

Embodiment 2

[0055] (1) In a glove box filled with argon (H 2 O2 13 ]-[TFSI], continue to stir in the dark for 8 hours, and finally add 10 g of Na with a particle size of 5 μm to 8 μm 3 Zr 2 Si 2 PO 12 Continue to stir in the dark for 3 h at a speed of 500 r / min, and finally obtain a homogeneous mixture.

[0056] (2) In a glove box filled with argon (H 2 O2 <0.1ppm), the mixture is coated on a polytetrafluoroethylene plate with a scraper, the thickness of the mixture coating is 150 μm, and the wavelength is 365nm, and the power is 400W ultraviolet lamp irradiation for 5min to cure, and after drying, a kind of light according to the present invention is obtained. Solidified solid composite electrolyte, the electrolyte is away from the side of the plate, the surface is smooth, the content of the inorganic solid electrolyte is small, and the polymer content is large as the side close to the metal negative electrode, which can effectively improve the compatibility between the electrolyte a...

Embodiment 3

[0060] (1) In a glove box filled with argon (H 2 O2 13 ]-[TFSI], continue to stir in the dark for 8 hours, and finally add 10g of Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Continue to stir in the dark for 3 h at a speed of 500 r / min, and finally obtain a homogeneous mixture.

[0061] (2) In a glove box filled with argon (H 2 O2 <0.1ppm), the mixture is coated on a polytetrafluoroethylene plate with a scraper, the thickness of the mixture coating is 150 μm, and the UV lamp with a wavelength of 365nm and a power of 400W is irradiated for 5min to cure, and after drying, one of the present invention is obtained. Light-cured solid composite electrolyte, the electrolyte is away from the side of the plate, the surface is smooth, the content of inorganic solid electrolyte is small, and the polymer content is large as the side close to the metal negative electrode, which can effectively improve the compatibility between the electrolyte and the alkali metal negative electrode and reduce the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com