Preparation method of PMMA-based gel polymer electrolyte

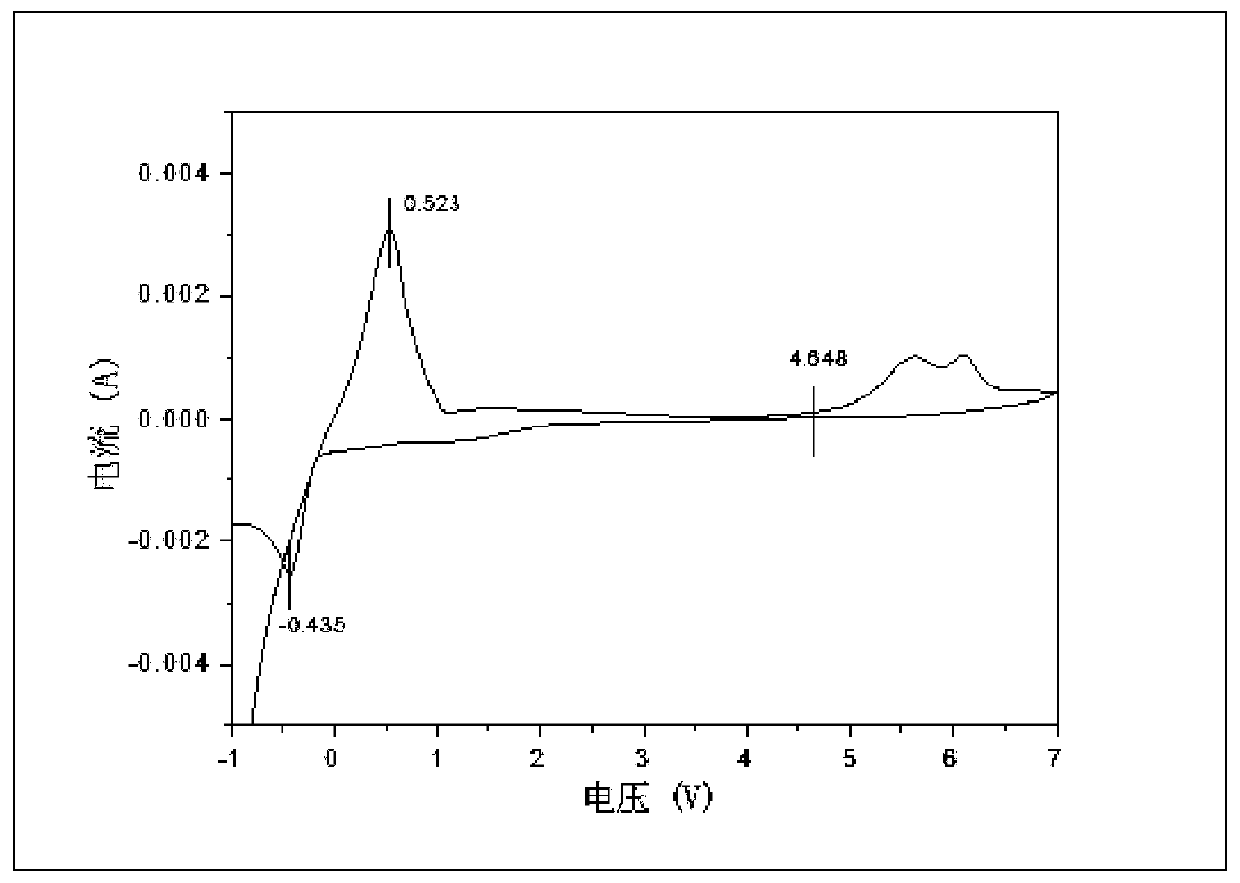

A polymer and electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of high brittleness of polymer films, inability to assemble and use, hindering the research of PMMA-based gel polymer electrolytes, etc., to achieve Effects of improving pore structure, increasing ionic conductivity, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

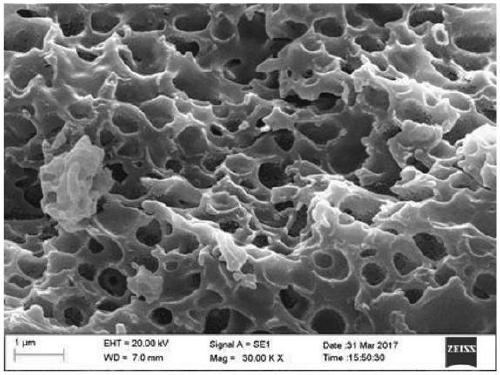

Image

Examples

preparation example Construction

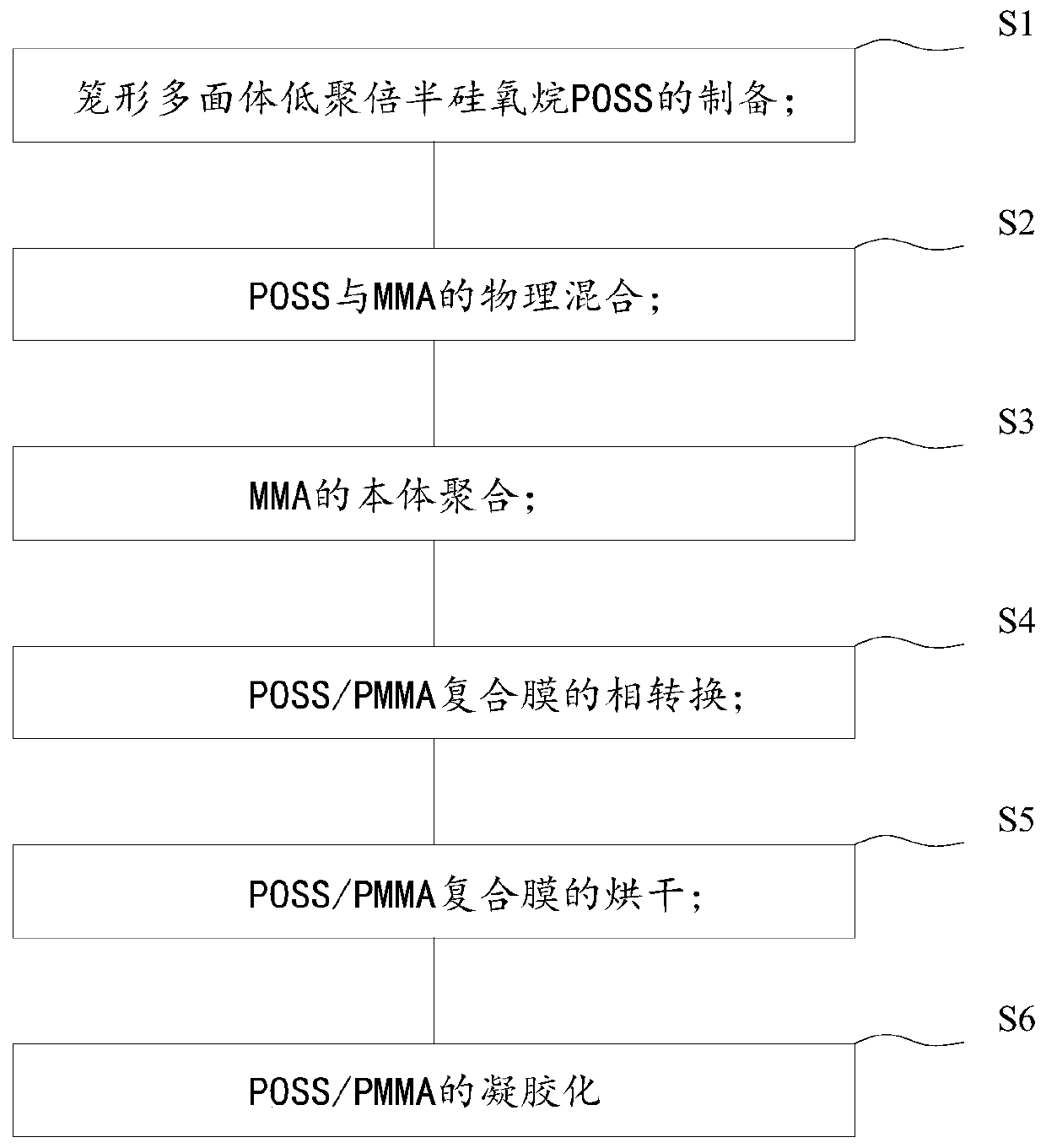

[0041] refer to figure 1 Shown, the invention provides a kind of preparation method of PMMA base gel polymer electrolyte, comprises steps:

[0042] S1: Preparation of clathrate polyhedral oligomeric silsesquioxane POSS.

[0043] Said step S1 includes the following processes:

[0044] (1) Seal and stir a certain volume ratio of ethyl acetate (EAC), vinyltrimethoxysilane (VTMS) and γ-methacryloxypropyltrimethoxysilane (MPS) for 10-60min, and mix Uniform;

[0045] (2), the preparation volume fraction is the hydrochloric acid aqueous solution of 10%~50%, it is added dropwise in the mixed solution of step (1);

[0046] (3), sealing and stirring the mixture in step (2) in a water bath at 20-40°C for 2-8 days;

[0047] (4), the product obtained in step (3) is repeatedly washed and suction-filtered more than 3 times with a sufficient amount of methanol;

[0048] (5) Baking the product obtained in step (4) under vacuum at 60-80° C. for more than 12 hours to obtain POSS.

[0049] ...

Embodiment 1

[0069] Example 1 - POSS content 5%

[0070]Mix EAC, VTMS and MPS in a volume ratio of 12:3:1, and after airtight stirring for 10 min, then add 30% hydrochloric acid aqueous solution dropwise to the mixed solution, then stir in a water bath at 20°C for 4 days, and let stand One day later, the product was repeatedly washed and filtered three times with a sufficient amount of methanol, and then vacuum-baked at 60° C. for 12 hours to obtain POSS nanoparticles. Then mix 0.03g POSS, 0.57g MMA and 0.8ml DMF, stir in a water bath at 70°C until POSS / MMA is completely dissolved, immediately apply the hot solution on polypropylene non-woven fabric, immerse in 50% hydrochloric acid aqueous solution, keep it for 1 hour, then take it out Air-dried at room temperature for 12 hours, and then transferred to a 60°C oven for vacuum baking for 6 hours to obtain a 5% POSS / PMMA composite membrane. The composite membrane was soaked in 1mol / L LiPF6 electrolyte for 20 minutes to obtain a gel polymer...

Embodiment 2

[0071] Example 2 - POSS content 10%

[0072] Mix EAC, VTMS and MPS in a volume ratio of 12:3:1, and after airtight stirring for 10 min, then add 30% hydrochloric acid aqueous solution dropwise to the mixed solution, then stir in a water bath at 20°C for 4 days, and let stand One day later, the product was repeatedly washed and filtered three times with a sufficient amount of methanol, and then vacuum-baked at 60° C. for 12 hours to obtain POSS nanoparticles. Then mix 0.06g POSS, 0.54g MMA and 0.8ml DMF, stir in a 70°C water bath until the POSS / MMA is completely dissolved, immediately apply the hot solution on the polypropylene non-woven fabric, immerse in 50% hydrochloric acid aqueous solution, keep it for 1h, take it out Air-dried at room temperature for 12 hours, and then transferred to a 60°C oven for vacuum baking for 6 hours to obtain a 10% POSS / PMMA composite membrane. The composite membrane was soaked in 1mol / L LiPF6 electrolyte for 20 minutes to obtain a gel polymer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com