Copper-doped low-temperature phosphomolybdic acid denitration catalyst and preparation method thereof

A low-temperature denitration and phosphomolybdic acid technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as poor ability, increase exposure, enhance redox and electron storage capacity, improve The effect of low temperature denitration activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

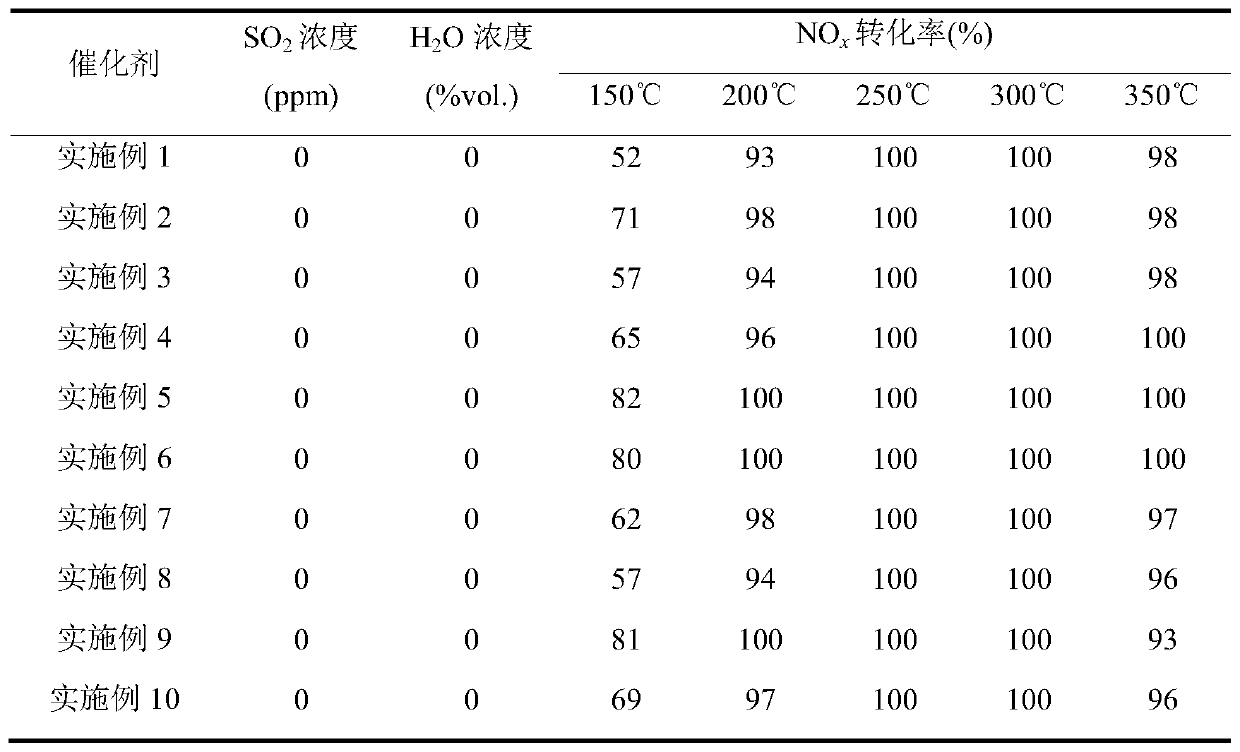

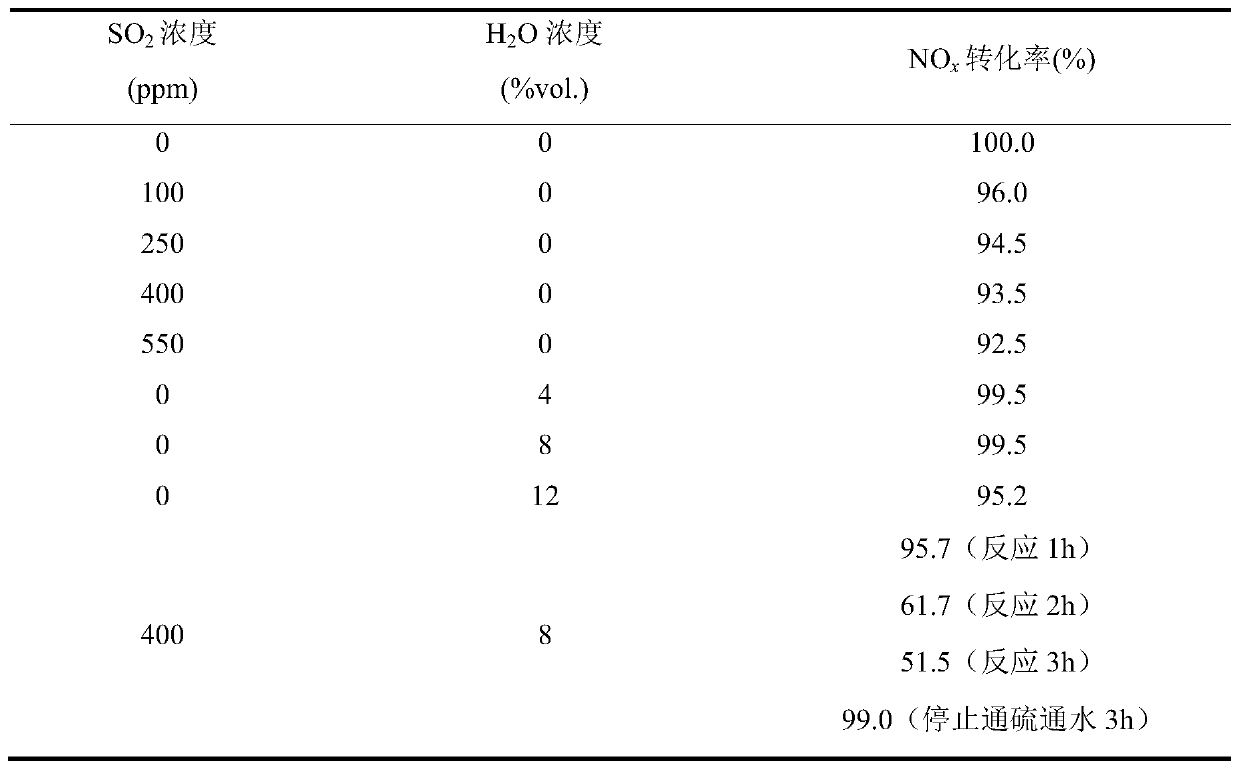

Examples

Embodiment 1

[0060] Step 1: Preparation of Active Components

[0061] The first step, weigh 1g phosphomolybdic acid, 0.005g PEG (by weighing 0.5% by mass of phosphomolybdic acid) and 2g copper nitrate (control Cu and Mo mol ratio to be 2: 1) and put them in the crucible, add 40ml distilled water to dissolve , stir at a constant speed for 1 h on a magnetic stirrer, and control the stirring temperature to be 25 °C; in the second step, dry the mixture in the first step at a constant speed on a magnetic stirrer, evaporate the water to dryness, and control the drying temperature to be 85 °C; In the third step, the mixture in the second step is placed in a drying oven for constant temperature drying, and the drying temperature is controlled to be 105°C; in the fourth step, the mixture dried in the third step is placed in a muffle furnace for calcination at 350°C for 3 hours. The active ingredient is obtained after cooling.

[0062] Step 2: Preparation of the catalyst

[0063] In the first step...

Embodiment 2

[0065] Step 1: Preparation of Active Components

[0066] The first step, weigh 1g phosphomolybdic acid, 0.005g PEG (by weighing 0.5% of phosphomolybdic acid mass) and 4.7658g copper nitrate (control Cu and Mo mol ratio to be 3: 1) put into the crucible, add 40ml distilled water Dissolve, stir at a constant speed on a magnetic stirrer for 1 h, and control the stirring temperature to be 25 °C; in the second step, dry the mixture in the first step at a constant speed on a magnetic stirrer, evaporate the water to dryness, and control the drying temperature to be 85 °C; In the third step, the mixture in the second step is placed in a drying oven for constant temperature drying, and the drying temperature is controlled to be 105°C; in the fourth step, the mixture dried in the third step is placed in a muffle furnace for calcination at 350°C for 3 hours. , the active component is obtained after cooling.

[0067] Step 2: Preparation of the catalyst

[0068] In the first step, weigh 0....

Embodiment 3

[0070] Step 1: Preparation of Active Components

[0071] The first step, take by weighing 1g phosphomolybdic acid, 0.005g PEG (by weighing 0.5% of phosphomolybdic acid quality) and a certain amount of copper nitrate (controlling the Cu and Mo mol ratio to be 4: 1) put into the crucible, add 40ml distilled water Dissolve, stir at a constant speed on a magnetic stirrer for 1 h, and control the stirring temperature to be 25 °C; in the second step, dry the mixture in the first step at a constant speed on a magnetic stirrer, evaporate the water to dryness, and control the drying temperature to be 85 °C; In the third step, the mixture in the second step is placed in a drying oven for constant temperature drying, and the drying temperature is controlled to be 105°C; in the fourth step, the mixture dried in the third step is placed in a muffle furnace for calcination at 350°C for 3 hours. , the active component is obtained after cooling.

[0072] Step 2: Preparation of the catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com