Hollow silicon dioxide nanometer sphere and preparation method and application thereof

A technology of hollow silica and silica, applied in the direction of silica, silica, chemical instruments and methods, etc., can solve the problems of cumbersome process and high cost of hard template preparation, achieve simple and efficient operation, and increase loading capacity , The effect of not harsh process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

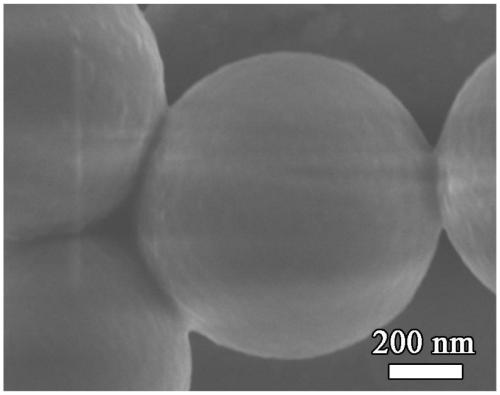

[0042] Preparation of the carbon sphere template in the example of the present invention: prepare 40mL of glucose solution with a concentration of 0.4M, stir magnetically for 0.5h until the glucose is fully dissolved, transfer to a stainless steel hydrothermal reaction kettle and react at 180°C for 6h. The reacted product was suction filtered, washed three times with deionized water and absolute ethanol, and dried in an oven at 50°C for future use. The prepared carbon sphere template is about 800 nm in size, uniform in size and good in dispersibility.

[0043] figure 1 It is the scanning electron microscope image of the prepared carbon sphere template agent, it can be seen that the size of the carbon sphere template agent is 800nm, the size is uniform, and the dispersion is good.

Embodiment 1

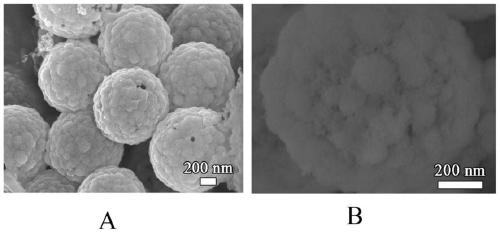

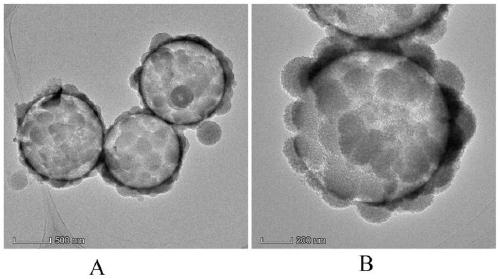

[0045] The preparation method of macroporous and mesoporous "raspberry-like" hollow silica nanospheres is as follows: put 0.05g of the above-mentioned carbon sphere template into a 100ml beaker, add 40mL of absolute ethanol and 10mL of deionized water respectively, and then ultrasonically 2h, so that the carbon spheres are fully dispersed. Add 0.08g CTAB (cetyltrimethylammonium bromide) to the dispersion of carbon spheres, stir for 10min to fully dissolve CTAB, then add 0.75mL of ammonia water, stir for 0.5h to fully mix the whole system. Then add 0.2mL TESO (tetraethyl orthosilicate), and continue to stir for 3h, so that the silicon source can be attached and hydrolyzed on the carbon sphere template. After fully hydrolyzed, the reactant was transferred to a stainless steel hydrothermal reaction kettle, and hydrothermally reacted at 180° C. for 4 h. Afterwards, the hydrothermal reaction product was suction-filtered, washed three times with deionized water and absolute ethanol...

Embodiment 2

[0050] Preparation of macroporous and mesoporous "raspberry-like" hollow silica nanospheres: put 0.05g of the above-mentioned carbon sphere template into a 100ml beaker, add 40mL of absolute ethanol and 10mL of deionized water, and then sonicate for 2h. Make the carbon spheres fully dispersed. Add 0.08g CTAB (cetyltrimethylammonium bromide) to the dispersion of carbon spheres, stir for 10min to fully dissolve CTAB, then add 0.25mL of ammonia water, stir for 0.5h to fully mix the whole system. Then add 0.2mL TESO (tetraethyl orthosilicate), and continue to stir for 3h, so that the silicon source can be attached and hydrolyzed on the carbon sphere template. After fully hydrolyzed, the reactant was transferred to a stainless steel hydrothermal reaction kettle, and hydrothermally reacted at 180° C. for 4 h. Afterwards, the hydrothermal reaction product was suction-filtered, washed three times with deionized water and absolute ethanol, and then dried in an oven at 50°C. Finally, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com