Micro-surface seal coat mixture and preparation method thereof

A technology of micro-surfacing and mixing materials, which is applied in the field of micro-surfacing sealing layer mixing materials and its preparation, can solve the problems of reflection cracks, poor waterproof effect, poor heat resistance, etc., and achieve good stress buffering performance and excellent water resistance The effect of scouring ability, structural stability and toughness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A kind of preparation method of micro-surface place sealing compound, wherein, preparation method comprises the following steps:

[0042] (1) Weigh cationic emulsified pitch, ethylene-1-octene copolymer, silicone resin, di-tert-butyl peroxide, triethylenediamine, sulfolane, vinyl palmitate, methyl trifluoropropyl silicone oil, Send it into a high-speed shear emulsifier, stir for 20-25 minutes at a temperature of 170-175°C, and then continuously shear for 60 minutes under the condition of 3000-3500r / min to obtain modified emulsified asphalt;

[0043] (2) Cool the modified emulsified asphalt to 20-30°C, add limestone, titanium nitride, aggregate, and water into the mixer and stir evenly to obtain the micro-surface sealing layer mixture.

Embodiment 1

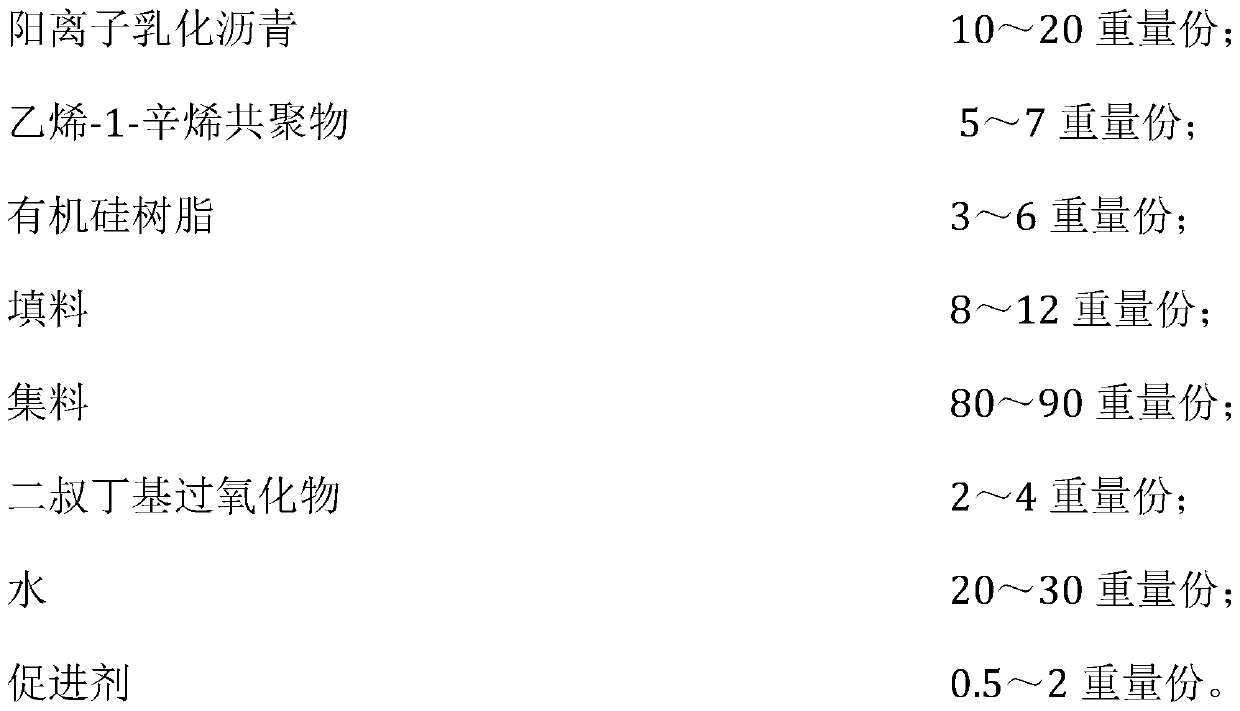

[0046] A kind of micro-surfacing sealing compound, comprising the following materials by weight:

[0047]

[0048]

[0049] Aggregate comprises 60wt% coarse aggregate and 40wt% fine aggregate, coarse aggregate is basalt, fine aggregate is expanded perlite, the particle diameter of coarse aggregate is 5mm, and the particle diameter of described fine aggregate is 0.1mm; Filler consisted of 20 wt% limestone and 80 wt% titanium nitride; accelerator 60 wt% triethylenediamine and 40 wt% sulfolane.

[0050] A preparation method of a micro-surface sealing compound, the preparation method comprising the steps of:

[0051] (1) Weigh cationic emulsified pitch, ethylene-1-octene copolymer, silicone resin, di-tert-butyl peroxide, triethylenediamine, sulfolane, vinyl palmitate, methyl trifluoropropyl silicone oil, Send it into a high-speed shear emulsifier, stir for 20 minutes at a temperature of 170°C, and then continuously shear for 60 minutes under the condition of 3000r / min to ob...

Embodiment 2

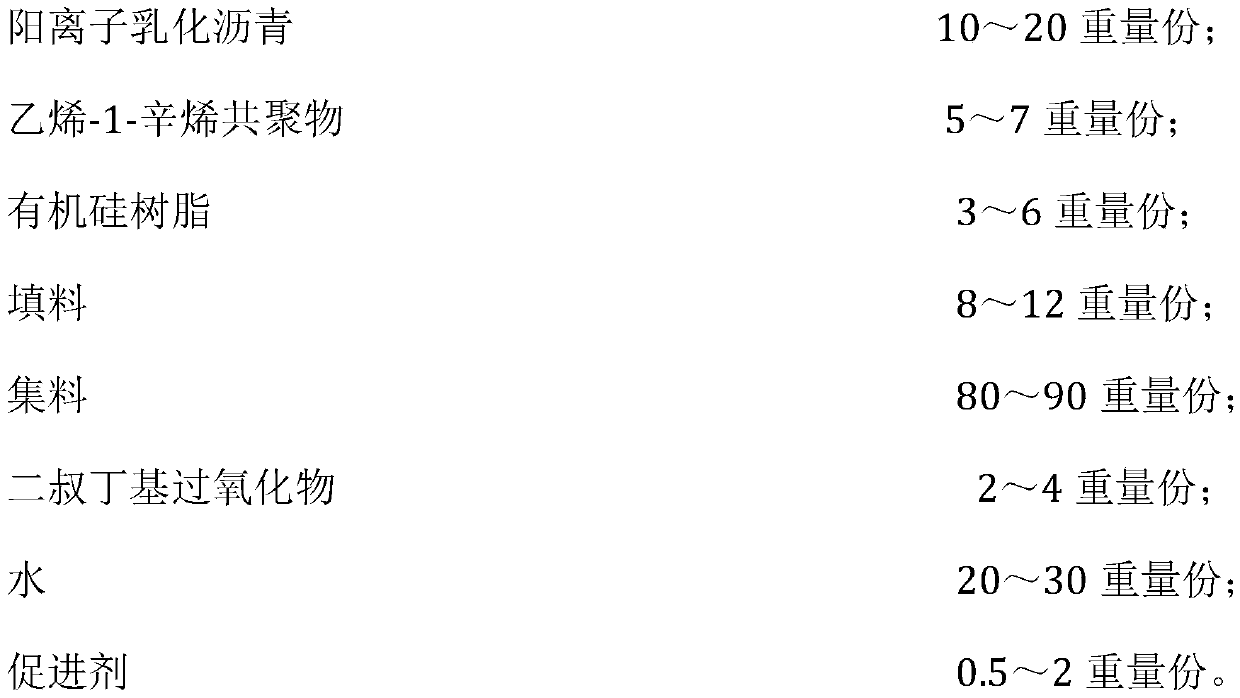

[0054] A kind of micro-surfacing sealing compound, comprising the following materials by weight:

[0055]

[0056]

[0057] Aggregate comprises 64wt% coarse aggregate and 36wt% fine aggregate, and coarse aggregate is limestone, and fine aggregate is diatomite, and the particle diameter of coarse aggregate is 8mm, and the particle diameter of described fine aggregate is 0.5mm, Filler consisted of 24 wt% limestone and 76 wt% titanium nitride; accelerator 63 wt% triethylenediamine and 37 wt% sulfolane.

[0058] A preparation method of a micro-surface sealing compound, the preparation method comprising the steps of:

[0059] (1) Weigh cationic emulsified pitch, ethylene-1-octene copolymer, silicone resin, di-tert-butyl peroxide, triethylenediamine, sulfolane, vinyl palmitate, methyl trifluoropropyl silicone oil, Send it into a high-speed shear emulsifier, stir for 24 minutes at a temperature of 172°C, and then continuously shear for 60 minutes under the condition of 3200r / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com