Self-lubrication and abrasion-resistantcomposite modification method for nano copper/microalloy layer on surface of metal

A metal surface and compound modification technology, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of high energy consumption and environmental pollution in the electroplating copper process, so as to improve the anti-stripping ability and avoid The effect of high energy consumption and high interfacial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

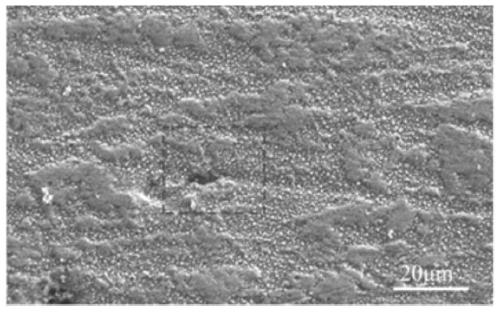

[0046] Preferred embodiment 1 of the present invention provides a method for self-lubricating and anti-corrosion composite modification of a nano-copper / micro-alloy layer on the surface of a metal workpiece. The metal workpiece is a QT500-7 ductile iron crankshaft, which includes the following steps:

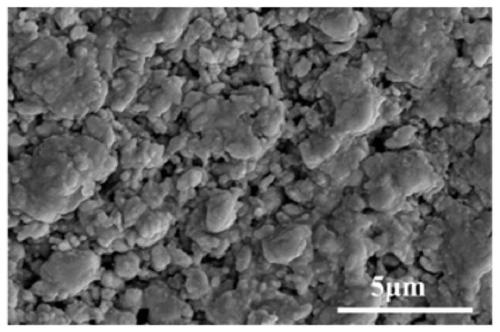

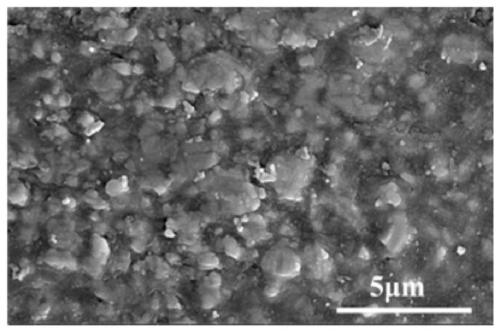

[0047]S1 uniformly mix nano-copper oxide particles and binder to form a slurry, and adjust the viscosity of the slurry to 2100cps by adding absolute ethanol to obtain a modified nano-copper oxide slurry; the particle size of the nano-copper oxide particles is ≤ 100nm , the binder is a mixture of terpineol and ethyl cellulose (the mass ratio of the two is 9:1), and the mass ratio between the nano-copper oxide particles and the binder is 1.8:1. Among them, the viscosity is adjusted to make the coating better applied to the surface of the workpiece, and absolute ethanol can volatilize during the drying process, avoiding the introduction of impurity elements, and the volatilization p...

Embodiment 2

[0052] Preferred embodiment 2 of the present invention provides a method for self-lubricating and anti-corrosion compound modification of a nano-copper / micro-alloy layer on the surface of a metal workpiece. The metal workpiece is a QT500-7 ductile iron crankshaft, comprising the following steps:

[0053] S1 uniformly mix the nano-copper oxide particles and the binder to form a slurry, and adjust the viscosity of the slurry to 2100cps by adding absolute ethanol to obtain a modified nano-copper oxide slurry; wherein, the particle size of the nano-copper oxide particles ≤100nm, the binder is a mixture of terpineol and ethyl cellulose (the mass ratio of the two is 9:1), and the mass ratio between the nano copper oxide particles and the binder is 1.8:1.

[0054] After the semi-finishing of the S2 workpiece, it is vacuum annealed at 600°C for 4 hours to eliminate stress, and then it is finished, and then the modified nano-copper oxide slurry is coated on the surface of the workpiece....

Embodiment 3

[0074] The preferred embodiment 3 of the present invention provides a self-lubricating and anti-corrosion composite modification method of nano-copper / micro-alloy layer on the surface of a metal workpiece. The metal workpiece is a 42CrMo quenched and tempered gear, comprising the following steps:

[0075] S1 uniformly mix nano-copper oxide particles and binder to form a slurry, and adjust the viscosity of the slurry to 2000cps by adding absolute ethanol to obtain a modified nano-copper oxide slurry; wherein, the particle size of the nano-copper oxide particles ≤100nm, the binder is a mixture of terpineol and ethyl cellulose (the mass ratio of the two is 6:4), and the mass ratio between the nano copper oxide particles and the binder is 1.6:1.

[0076] S2 The workpiece is cleaned to remove oil and rust, and then apply the modified nano-copper oxide slurry on the surface of the workpiece. The thickness of the coated slurry is 7 μm, and then place the workpiece in a drying oven to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com