Lithium ion battery interlayer solid-state electrolyte and a preparation method thereof

A solid-state electrolyte, lithium-ion battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of poor interface performance and low conductivity of all-solid-state electrolytes, achieve soft interface contact, simple preparation process, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

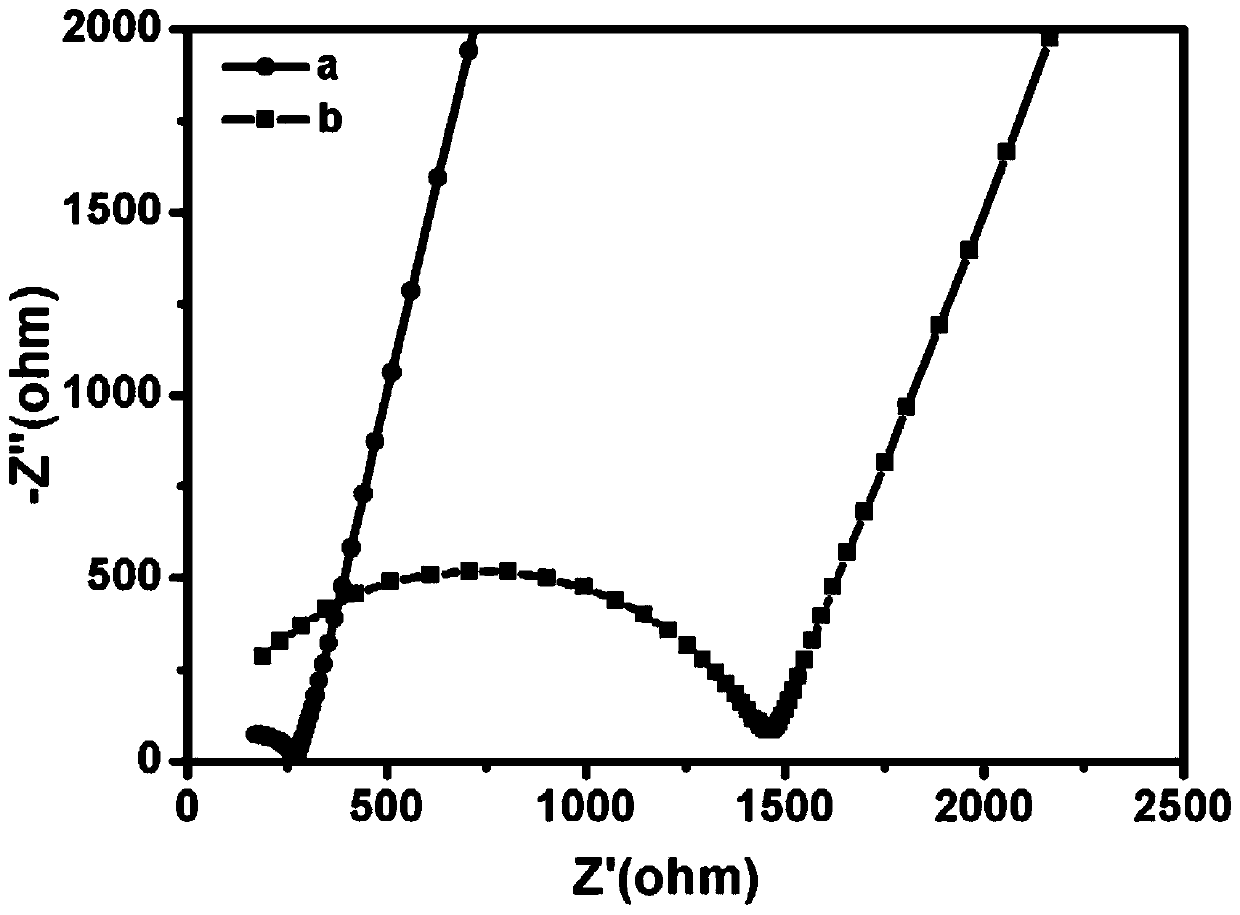

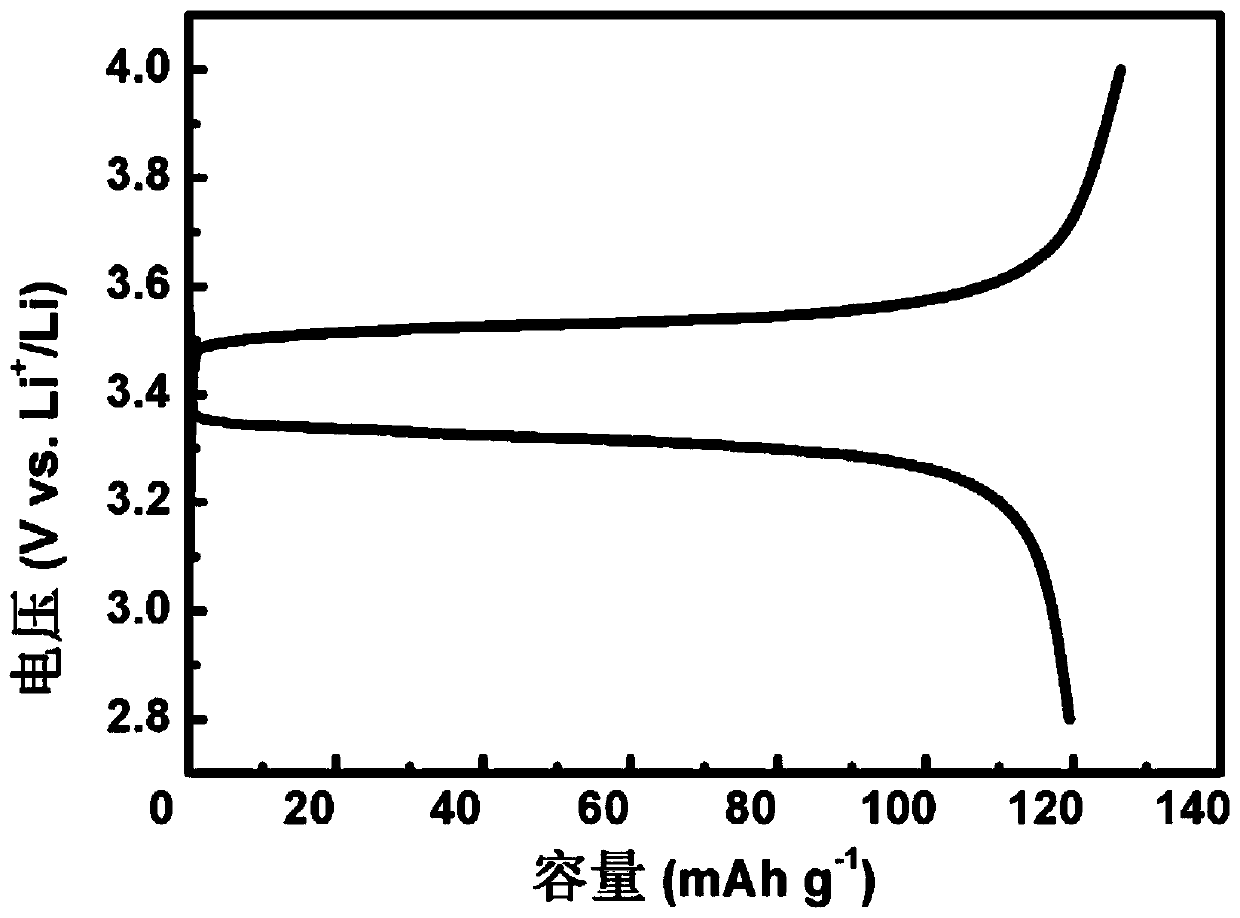

[0031] (1) Take 1.5g of PAN powder and add it to the DMF solvent to make a mixed solution with a mass fraction of 15% of PAN, add LLZO nanoparticles with a mass fraction of 20% (relative to the interlayer solid electrolyte of lithium-ion batteries), and stir with a magnetic stirrer 6h to make it fully dispersed to obtain a uniform spinning precursor solution; under the conditions of an injection speed of 1.2ml / h, a spinning voltage of 25kv, a spinning distance of 18cm, and a roller receiving (roller speed 500r / min) Electrospinning is performed; after spinning, the electrospun film is put into an oven, and dried at 80° C. for 12 hours to completely evaporate the solvent. The obtained film is standby;

[0032] (2) Take 1g PAN, 0.6g LiTFSI and put them into 15ml NMP and stir them fully at 45°C for 9h, then pour them into a polytetrafluoroethylene mold. The drying time is 24h in the argon atmosphere in the glove box, and 24h in vacuum at 35°C. Obtain the polymer electrolyte membr...

Embodiment 2

[0036] (1) Take 1.5g of PAN powder and add it to the DMF solvent to make a mixed solution with a mass fraction of 15% of PAN, then add LLZO nanoparticles with a mass fraction of 10% (relative to the interlayer solid electrolyte of lithium-ion batteries), and use a magnetic stirrer Stir for 6 hours to make it fully dispersed to obtain a uniform spinning precursor solution; at an injection speed of 1.2 ml / h, a spinning voltage of 10kv, and a spinning distance of 10cm, the conditions of using a roller to receive (roller speed 500r / min) After the spinning, the electrospun film was placed in an oven, and dried at 40° C. for 6 hours to completely evaporate the solvent. The obtained film is standby;

[0037] (2) Take 1g PAN, 0.3g LiTFSI and put them into 15ml NMP and stir them well at 30°C for 6h, then pour them into a polytetrafluoroethylene mold. The drying time is 6h in argon atmosphere in the glove box, and 6h in vacuum at 20°C. Obtain the polymer electrolyte membrane for subseq...

Embodiment 3

[0041](1) Take 1.5g of PAN powder and add it to the DMF solvent to make a mixed solution with a mass fraction of 15% of PAN, add LLZO nanoparticles with a mass fraction of 30% (relative to the interlayer solid electrolyte of lithium-ion batteries), and stir with a magnetic stirrer 6h to make it fully dispersed to obtain a uniform spinning precursor solution; under the conditions of an injection speed of 1.2 ml / h, a spinning voltage of 18kv, a spinning distance of 14cm, and a roller receiving (roller speed 500r / min) Electrospinning is carried out; after spinning, the electrospun film is put into an oven, and dried at 60°C for 9 hours to completely evaporate the solvent. The obtained film is standby;

[0042] (2) Take 1g PAN, 0.1g LITFSI and put them into 15ml NMP and stir well at 60°C for 12h, then pour them into a polytetrafluoroethylene mold, and dry them in a glove box for 15h under argon atmosphere, and 15h under vacuum at 50°C Obtain the polymer electrolyte membrane for s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com