Bio-based superhydrophobic anti-icing coating with array microstructure and preparation method thereof

A bio-based, micro-structured technology, applied in coatings, devices for coating liquid on the surface, anodic oxidation, etc., can solve the problems of poor environmental protection, single preparation shape, etc., and achieve high production efficiency, simple preparation method, and good application and the effect of development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

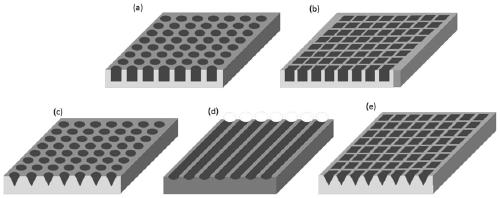

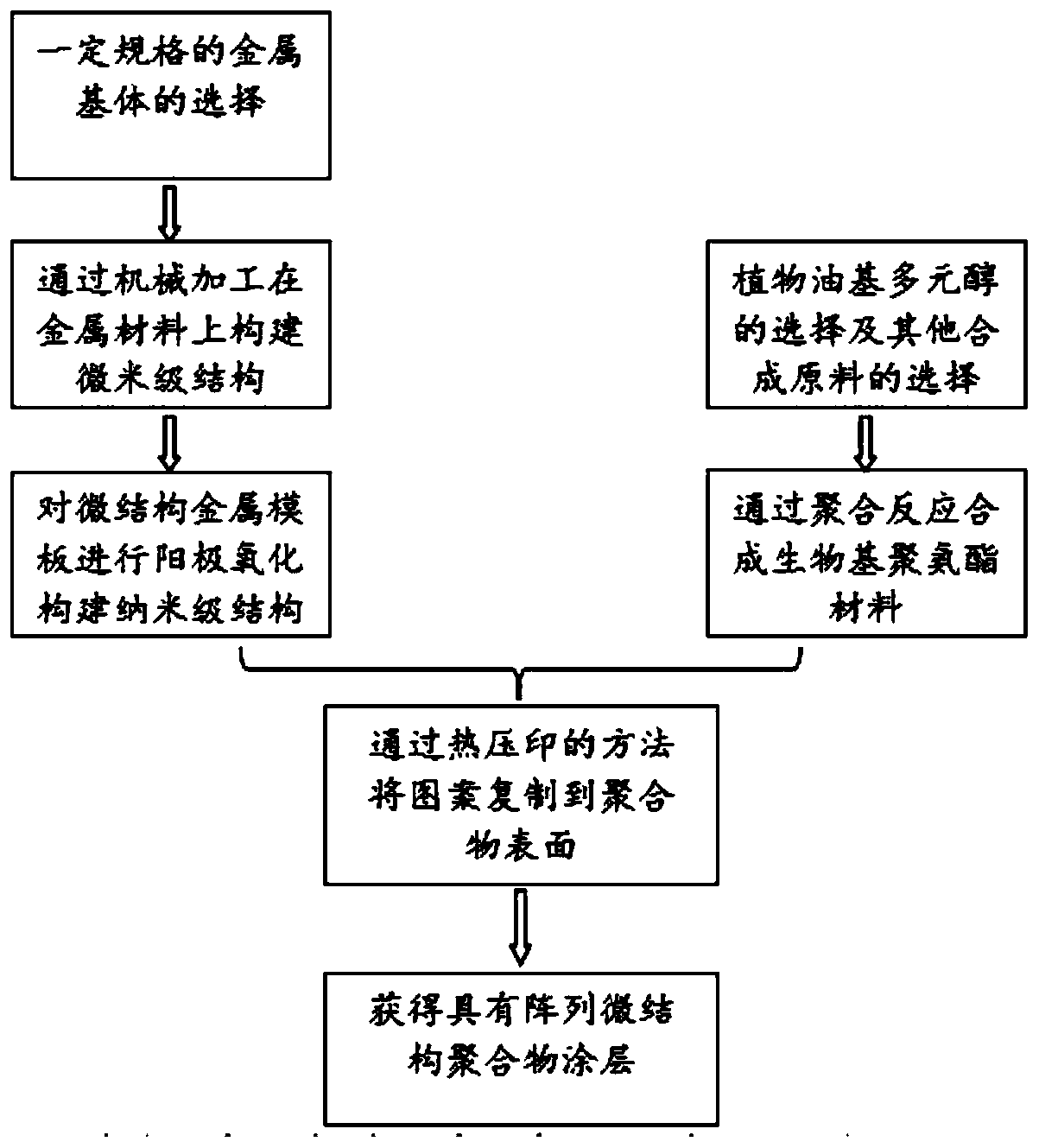

[0033] A preparation method of a bio-based superhydrophobic anti-icing coating with an array microstructure, comprising the following steps:

[0034](1) Using the aluminum alloy material as the base, the aluminum alloy material is cut into a square template with a side length of 1cm and a thickness of 0.2mm, and then uses a micron-scale electrochemical machining process to build a diameter of 60 μm and a height of 40 μm on the aluminum alloy template , cylindrical pits with a spacing of 100 μm, then cleaned with ethanol and deionized water, and dried for later use; the process parameters of the micron-scale electrochemical machining: the electrode material is a tungsten wire with a diameter of 10 μm, the negative electrode voltage of the power supply is 4v, the pulse width is 60ns, and the pulse frequency ≤25MHz, the motor feed speed is 5μm / min, the electrolyte is 0.15mol / L dilute hydrochloric acid solution, the pulse current between the electrodes is 1.5mA; The pulse current ...

Embodiment 2

[0040] A preparation method of a bio-based superhydrophobic anti-icing coating with an array microstructure, comprising the following steps:

[0041] (1) Using the copper alloy material as the substrate, cut the copper alloy material into a square template with a side length of 1cm and a thickness of 0.2mm, and then use micron-scale electrochemical machining to construct a template with a diameter of 60 μm and a depth of 45 μm on the copper alloy substrate template , cylindrical pits with a spacing of 100 μm, then cleaned with ethanol and deionized water, and dried for later use; the process parameters of the micron-scale electrochemical machining: the electrode material is a tungsten wire with a diameter of 10 μm, the negative electrode voltage of the power supply is 4v, the pulse width is 60ns, and the pulse frequency ≤25MHz, the motor feed speed is 5μm / min, the electrolyte is 0.15mol / L dilute hydrochloric acid solution, the pulse current between the electrodes is 1.5mA; The...

Embodiment 3

[0047] A preparation method of a bio-based superhydrophobic anti-icing coating with an array microstructure, comprising the following steps:

[0048] (1) Using the aluminum alloy material as the base, cut the aluminum alloy material into a square formwork with a side length of 1cm and a thickness of 0.2mm, and then use a micron-scale electrochemical machining process to build a height of 40μm on the aluminum alloy formwork, a width of 60μm, and a spacing of A cylindrical pit of 60 μm, then cleaned with ethanol and deionized water, dried for later use; the technical parameters of the micron-scale electrochemical processing: the electrode material is a tungsten wire with a diameter of 10 μm, the negative electrode voltage of the power supply is 4v, the pulse width is 60ns, and the pulse frequency is ≤25MHz , the motor feed speed is 3μm / min, the electrolyte is 0.2mol / L dilute hydrochloric acid solution, and the pulse current between the electrodes is 1.5mA; The pulse current betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Static water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com