Method for preparing porous titanium with titanium sesquioxide

A technology of dititanium trioxide and porous titanium, which is applied in the field of porous titanium preparation, can solve the problems of low connection strength and difficult block formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

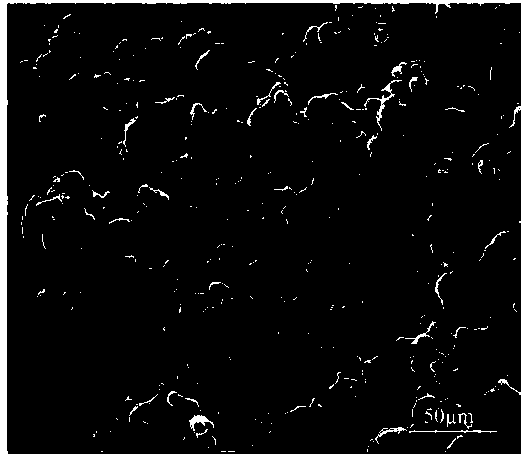

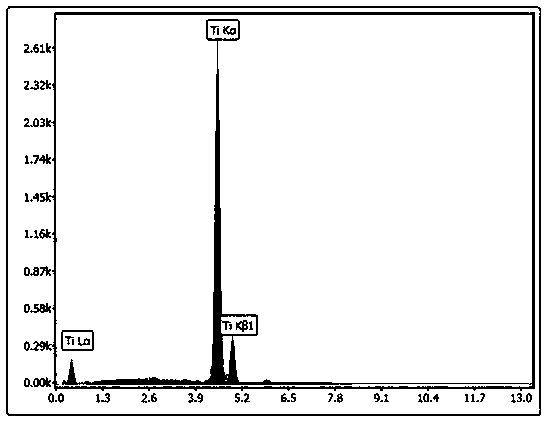

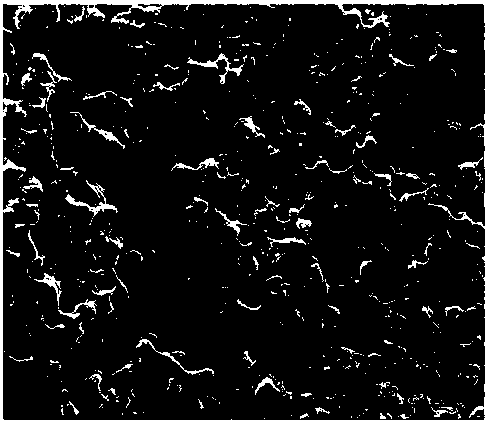

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of method that prepares porous titanium by dititanium trioxide, concrete steps are as follows:

[0027] (1) Mix titanium dioxide powder and calcium chloride evenly to obtain Ti 2 o 3 / CaCl 2 Mixed powder; wherein the mass ratio of titanium dioxide powder and calcium chloride is 6:1;

[0028] (2) The Ti in step (1) 2 o 3 / CaCl 2 The mixed powder is press-molded to obtain a preform; wherein the thickness of the preform is 5mm; wherein the pressure of the compression molding is 4Mpa, the diameter of the preform is 10mm, and the shape of the preform is a cylindrical block;

[0029] (3) Put the preform in step (2) into a vacuum and sinter at 850°C for 30 minutes to obtain a porous precursor; the degree of vacuum is 15Pa;

[0030] (4) Under the conditions of a pressure of 9 Pa and a temperature of 1000°C, the porous precursor of step (3) was reduced with calcium vapor for 6 hours;

[0031] (5) Dilute the reduction product of step (4) with dilute hy...

Embodiment 2

[0035] Embodiment 2: a kind of method for preparing porous titanium by dititanium trioxide, concrete steps are as follows:

[0036] (1) Mix titanium dioxide powder and calcium chloride evenly to obtain Ti 2 o 3 / CaCl 2 Mixed powder; wherein the mass ratio of titanium dioxide powder and calcium chloride is 4:1;

[0037] (2) The Ti in step (1) 2 o 3 / CaCl 2 The mixed powder is press-molded to obtain a preform; wherein the thickness of the preform is 8mm; wherein the pressure of the compression molding is 2Mpa, the diameter of the preform is 10mm, and the shape of the preform is a cylindrical block;

[0038] (3) Sintering the preform in step (2) in an argon atmosphere at a temperature of 900°C for 60 minutes to obtain a porous precursor;

[0039] (4) At a pressure of 10 -1 Pa and the temperature are 1000°C, using calcium vapor to reduce the porous precursor in step (3) for 6h;

[0040] (5) Dilute the reduction product of step (4) with dilute hydrochloric acid solution for...

Embodiment 3

[0044] Embodiment 3: a kind of method that prepares porous titanium by dititanium trioxide, concrete steps are as follows:

[0045] (1) Mix titanium dioxide powder and calcium chloride evenly to obtain Ti 2 o 3 / CaCl 2 Mixed powder; wherein the mass ratio of titanium dioxide powder and calcium chloride is 5:1;

[0046] (2) The Ti in step (1) 2 o 3 / CaCl 2 The mixed powder is press-molded to obtain a preform; wherein the thickness of the preform is 6mm; wherein the pressure of the compression molding is 4Mpa, the diameter of the preform is 15mm, and the shape of the preform is a cylindrical block;

[0047] (3) Sintering the preform in step (2) in an argon atmosphere at a temperature of 1000°C for 120 minutes to obtain a porous precursor;

[0048] (4) Under the conditions of a pressure of 5 Pa and a temperature of 900°C, the porous precursor of step (3) was reduced with calcium vapor for 12 hours;

[0049] (5) Dilute the reduction product of step (4) with dilute hydrochlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com