Forming method for preparing photonic crystal workpiece with different structural colors based on nano composite

A photonic crystal and structural color technology, which is applied in the field of plastic processing and forming, can solve the problems that affect the application of photonic crystal structural color materials, small product area, poor mechanical properties, etc., and achieve excellent structural color optical properties, broaden types, and good hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, the thermosetting cross-linked polystyrene raw material coated with thermoplastic polytetrahydrofuran is taken as an example, and the method described in the present invention is used to extrude and roll to form high-quality large-area photonic crystal structural color products with mechanical strength. The implementation steps are as follows:

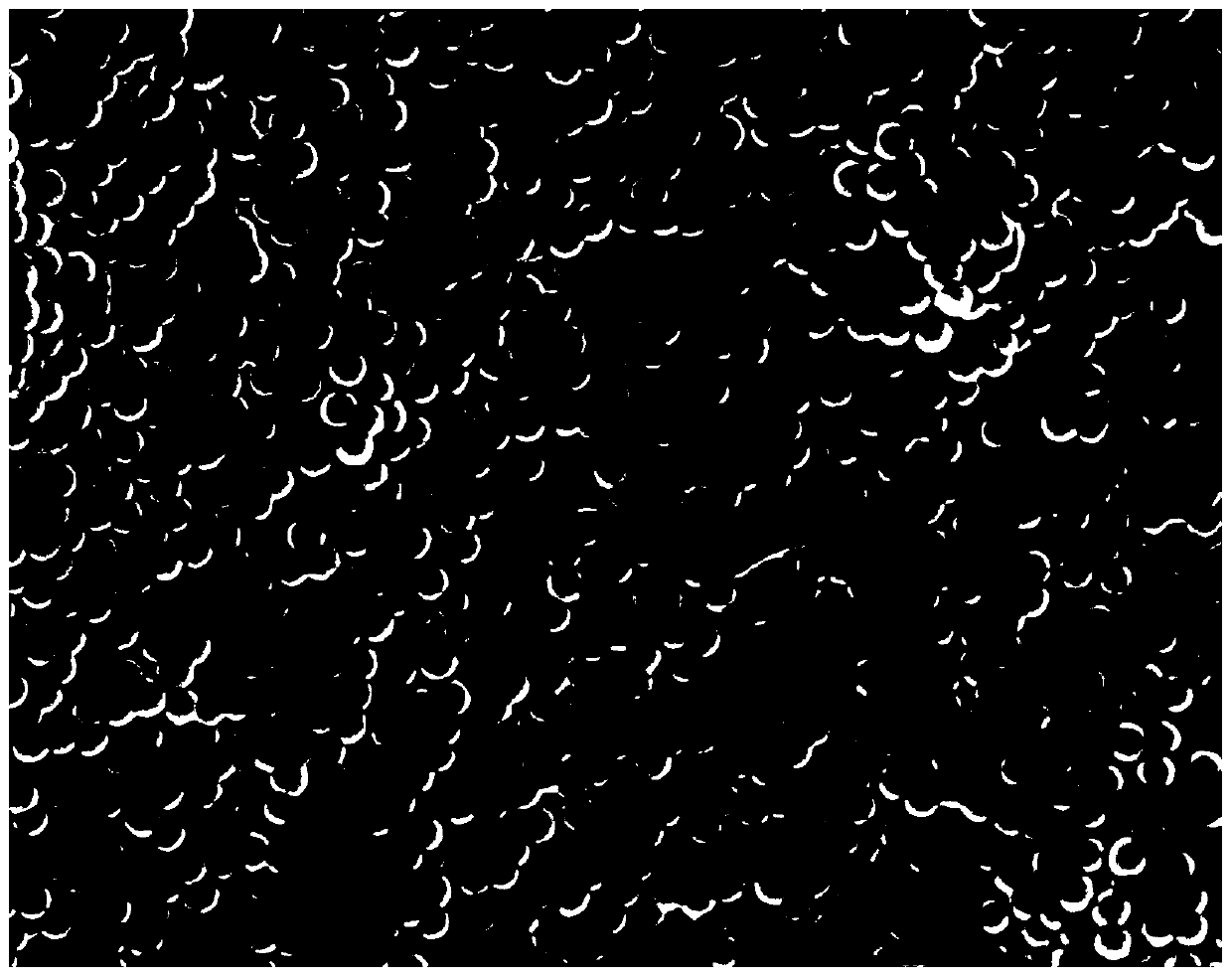

[0044]1) Prepare the thermosetting nano-microsphere particle material: through styrene polymerization, the water in the emulsion polymerization system is 270g, and the temperature is 70-90°C at 100-600rpm stirring reaction for 5-10 hours. 0.0100-0.3000g is regulated to obtain microsphere particles of different nanometer scales, and 1-15g of cross-linking agent is added to obtain thermosetting polystyrene microsphere particle emulsion. After the freeze-drying is completed, the thermosetting polystyrene microsphere particle powder is obtained, and the powder has a nanoscale microsphere structure with a particle...

Embodiment 2

[0053] In this embodiment, the thermosetting cross-linked PMMA raw material coated with thermoplastic PEA is taken as an example, and the method described in the present invention is used to extrude and roll form a high-quality photonic crystal structure color product with large area and mechanical strength. The implementation steps are as follows:

[0054] 1) Prepare thermosetting nano-microsphere particle material: obtain thermosetting cross-linked PMMA nano-microsphere particle emulsion with a particle size of 100-500nm through emulsion polymerization, adjust the content of emulsifier during the polymerization process to adjust the nanoscale of microsphere particles, regulate the cross-linking The amount of the combined agent can be used to obtain nano-microspheres with different hardness. After the freeze-drying is completed, thermosetting cross-linked PMMA nano microsphere particles are obtained.

[0055] 2) Coating thermoplastic polymer materials: first dissolve thermop...

Embodiment 3

[0063] In this embodiment, the thermosetting cross-linked PMMA raw material coated with thermoplastic PTHF is taken as an example, and the method described in the present invention is used to extrude and roll form a high-quality photonic crystal structure color product with large area and mechanical strength. The implementation steps are as follows:

[0064] 1) Prepare thermosetting nano-microsphere particle material: obtain thermosetting cross-linked PMMA nano-microsphere particle emulsion with a particle size of 100-500nm through emulsion polymerization, adjust the content of emulsifier during the polymerization process to adjust the nanoscale of microsphere particles, regulate the cross-linking The amount of the combined agent can be used to obtain nano-microspheres with different hardness. After the freeze-drying is completed, thermosetting cross-linked PMMA nano microsphere particles are obtained.

[0065] 2) Coating thermoplastic polymer materials: first dissolve thermo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com