Ultrafine aluminum hydroxide and preparation method and application thereof

A technology of ultra-fine aluminum hydroxide and sodium aluminate, applied in the field of aluminum hydroxide, can solve problems such as unfavorable industrial production, limited source of raw materials, large equipment investment, etc., and achieves convenient long-term recycling, green process technology, and production and operation. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] (1) Coarse particle Al(OH) 3 Mix with distilled water according to the mass ratio of 1:3, and use a ball mill to grind to obtain Al(OH) containing fine particles 3 The first slurry, fine particle Al(OH) 3 the D 501.05μm;

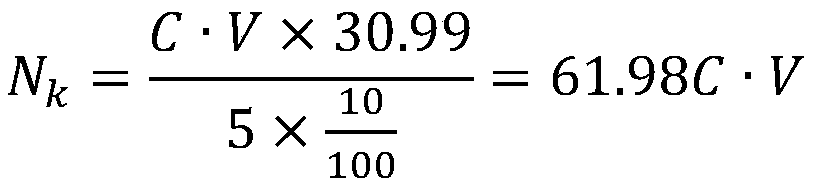

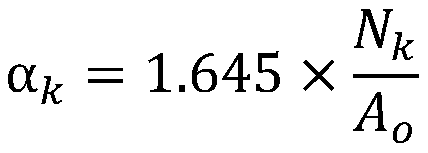

[0081] (2) Add the first slurry to α k 1.40, N k In the first supersaturated sodium aluminate solution of 172g / L, wherein, relative to 1L of supersaturated sodium aluminate solution, Al(OH) 3 The amount of the first slurry added is 3g; the seed crystals are decomposed at 30°C until the solid content is 80g / L;

[0082] (3) filter, wash the filter cake until the pH value is 9, obtain the seed filter cake;

[0083] (4) Mix the seed filter cake with distilled water at a mass ratio of 1:3, and use a ball mill to grind to obtain a mixture containing fine particles of Al(OH) 3 The second slurry, fine particle Al(OH) 3 the D 50 1.21μm;

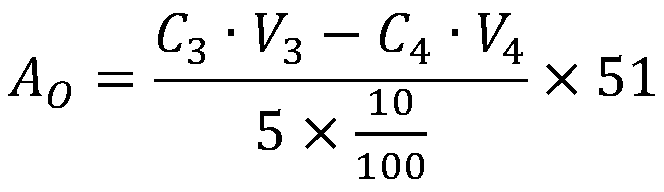

[0084] (5) Add the second slurry dropwise to α k In the unsaturated sodium aluminate solution of 2.85, wherein, ...

Embodiment 2

[0088] (1) Coarse particle Al(OH) 3 Mix with distilled water at a mass ratio of 1:3, and use a ball mill to grind to obtain Al(OH) containing fine particles 3 The first slurry, fine particle Al(OH) 3 the D 50 0.79μm;

[0089] (2) Add the first slurry to α k 1.22, N k In the first supersaturated sodium aluminate solution of 205g / L, wherein, relative to 1L of supersaturated sodium aluminate solution, Al(OH) 3 The amount of the first slurry added is 4g; the seed crystals are decomposed at 40°C until the solid content is 110g / L;

[0090] (3) filter, wash the filter cake until the pH value is 8.5, obtain the seed filter cake;

[0091] (4) Mix the seed filter cake with distilled water at a mass ratio of 1:3, and use a ball mill to grind to obtain a mixture containing fine particles of Al(OH) 3 The second slurry, fine particle Al(OH) 3 the D 50 1.41 μm;

[0092] (5) Add the second slurry dropwise to α k In the unsaturated sodium aluminate solution of 3.55, wherein, relativ...

Embodiment 3

[0096] (1) Coarse particle Al(OH) 3 Mix with distilled water at a mass ratio of 1:3, and use a ball mill to grind to obtain Al(OH) containing fine particles 3 The first slurry, fine particle Al(OH) 3 the D 50 1.42μm;

[0097] (2) Add the first slurry to α k 1.31, N k In the first supersaturated sodium aluminate solution of 150g / L, wherein, relative to 1L of supersaturated sodium aluminate solution, Al(OH) 3 The amount of the first slurry added is 2g; the seed crystals are decomposed at 35°C until the solid content is 100g / L;

[0098] (3) filter, wash the filter cake until the pH value is 8.5, obtain the seed filter cake;

[0099] (4) Mix the seed filter cake with distilled water at a mass ratio of 1:3, and use a ball mill to grind to obtain a mixture containing fine particles of Al(OH) 3 The second slurry, fine particle Al(OH) 3 the D 50 0.79μm;

[0100] (5) Add the second slurry dropwise to α k In the unsaturated sodium aluminate solution of 2.95, wherein, relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com