Electrochemical treatment system for printing ink wastewater

A technology for treating system and ink wastewater, which is applied in the field of environmental engineering, can solve problems such as rising prices of chemical raw materials, high cost of treatment systems, strong dependence on chemicals, etc., and achieves lower wastewater treatment costs, simple control process, and less dosage of chemicals Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

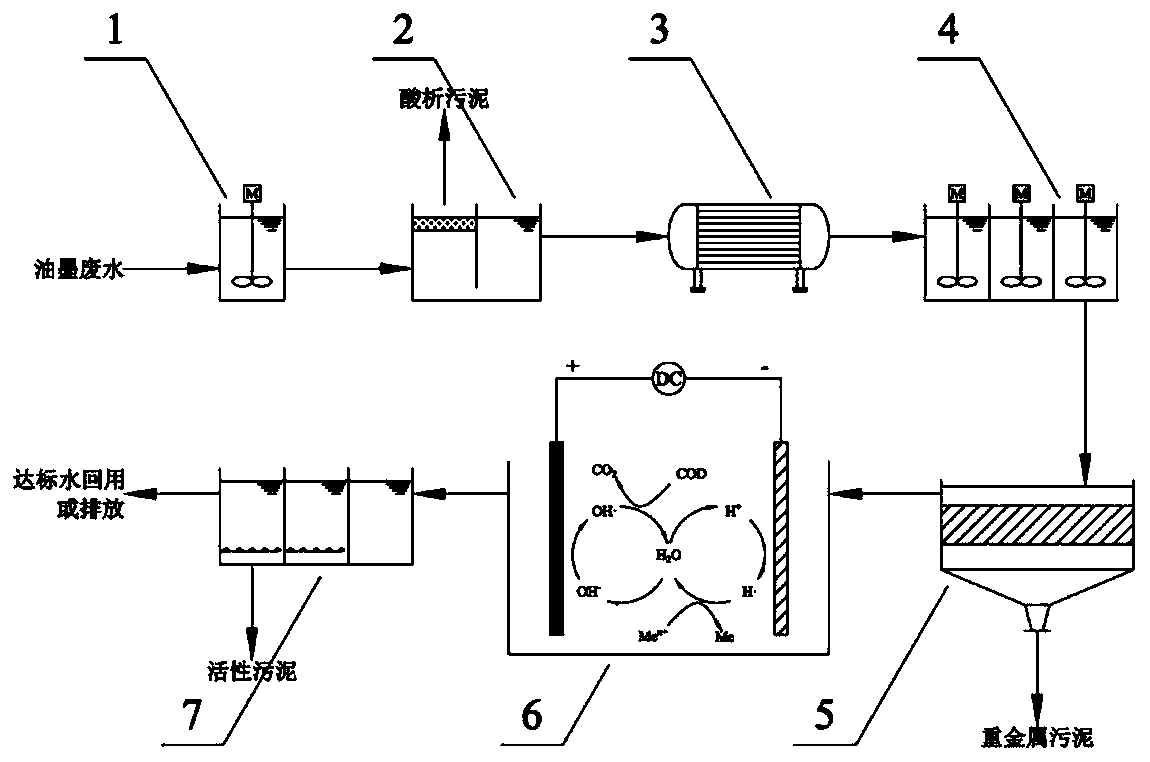

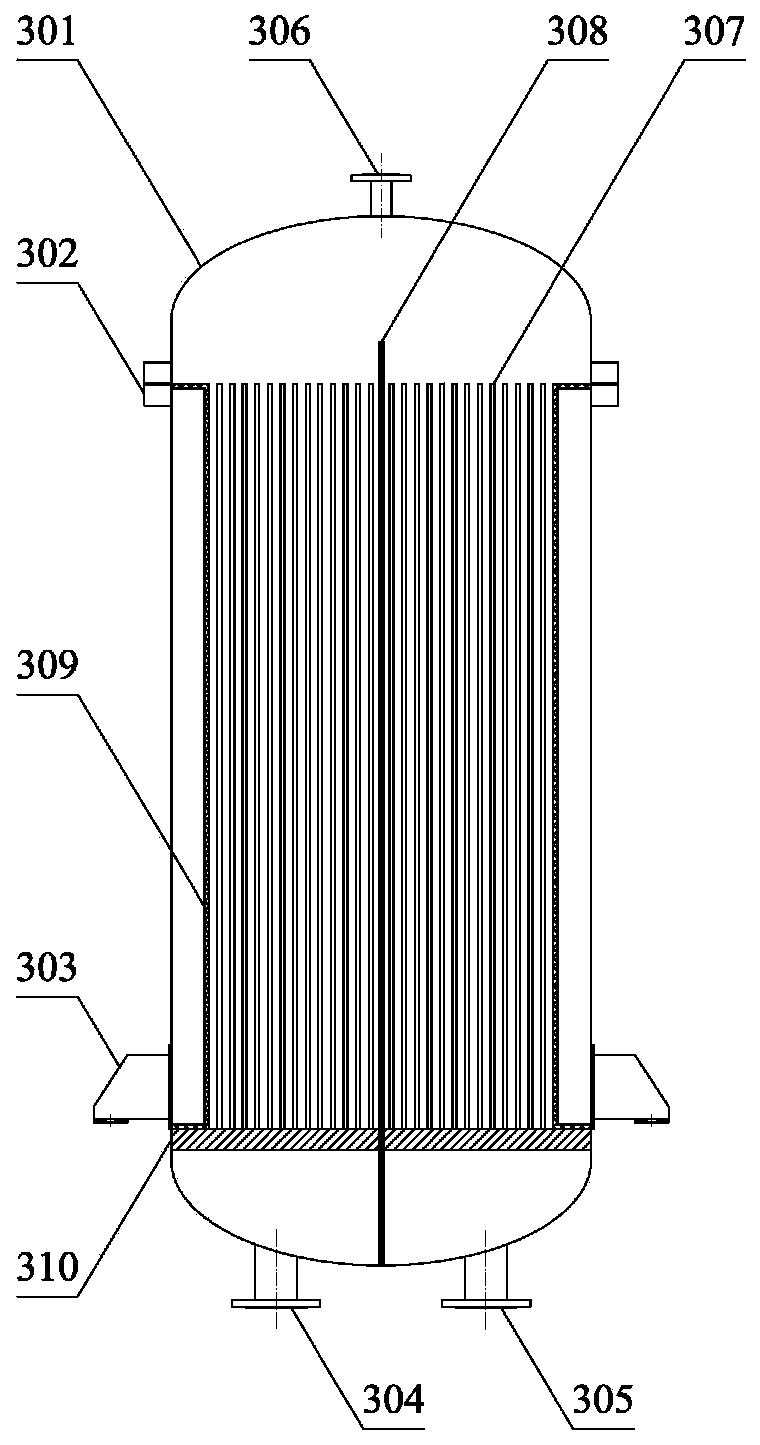

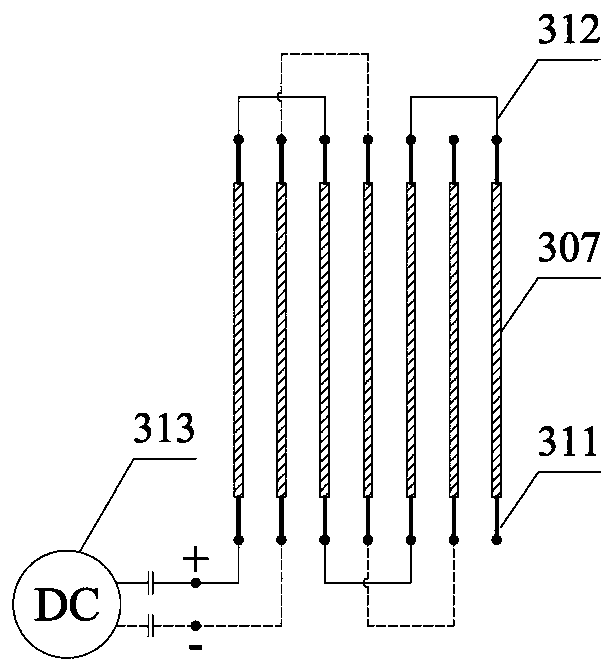

[0068] Example 1, such as Figure 1-5 As shown, an ink wastewater electrochemical treatment system includes a pH adjustment tank 1, an acid analysis tank 2, an electronic flocculator 3, a coagulation reaction tank 4, a clarifier 5, an electrocatalytic oxidation reactor 6, and a biochemical treatment device 7;

[0069] A pH adjustment pool 1 is used to input acid to reduce the pH of wastewater, and the pH adjustment pool 1 is connected to the acid analysis pool 2 through pipelines;

[0070] The acid analysis tank 2 is connected to the electronic flocculator 3 through pipelines;

[0071] The electronic flocculator 3 is used to destroy the stable state of the metastable substance, and the electronic flocculator 3 is connected to the coagulation reaction box 4 through a pipeline;

[0072] The coagulation reaction box 4 is used for adding alkali, coagulant and coagulant aid for reaction, and the coagulation reaction box 4 is connected with the clarifier 5 through pipelines;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com