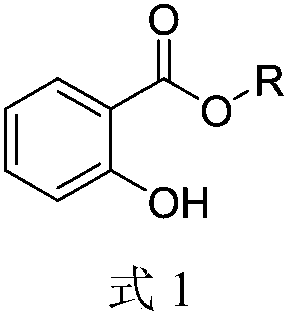

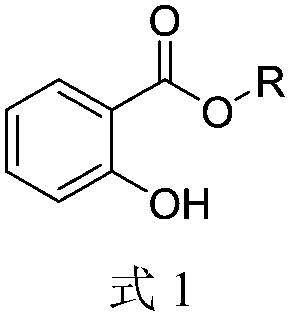

High-content liquid sodium salicylhydroxamic acid as well as preparation method and application thereof

A technology of sodium salicylate hydroxamate and salicylate, applied in solid separation, organic chemistry, flotation and other directions, can solve problems such as increasing the difficulty of wastewater treatment, achieve high product utilization rate and effective content, save production costs, The effect of improving product utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 50 grams of methyl salicylate and 0.6 grams of phenylethylphenol formaldehyde resin polyoxyethylene ether (Xingtai Lantian Fine Chemical Co., Ltd., Nongru 400#) into a three-necked flask, stir evenly, add 55 grams of water, and stir emulsification. Add 29.6 grams of hydroxylamine sulfate, after dissolving, add 95 grams of 40% sodium hydroxide solution dropwise, control the temperature of the reaction solution at 28-29° C. during the dropwise addition, and the pH value is not more than 12, after the dropwise addition (1.5 hours), Insulate and react for 3 hours, then raise the temperature to 40° C., and react for 3 hours. After the reaction was completed, the precipitated salt was removed by filtration to obtain a clear and transparent solution of sodium salicylhydroxamic acid. In terms of salicylhydroxamic acid, the content of salicylhydroxamic acid was 23.5%. The product is tracked by gas chromatography, and the product has good stability within 6 months without de...

Embodiment 2

[0047] Add 50 grams of methyl salicylate and 0.7 grams of phenylethylphenol formaldehyde resin polyoxyethylene ether (Xingtai Lantian Fine Chemical Co., Ltd., Nongru 400#) into a three-necked flask, stir well, add 55 grams of water, and stir emulsification. Add 29.6 grams of hydroxylamine sulfate, after dissolving, add 95 grams of 40% sodium hydroxide solution dropwise, control the temperature of the reaction solution at 28-29° C. during the dropwise addition, and the pH value is not more than 12, after the dropwise addition (1.5 hours), Insulate and react for 3 hours, then raise the temperature to 40° C., and react for 3 hours. After the reaction was completed, the precipitated salt was removed by filtration to obtain a clear and transparent solution of sodium salicylhydroxamic acid. In terms of salicylhydroxamic acid, the content of salicylhydroxamic acid was 23.4%. The product is tracked by gas chromatography, and the product has good stability within 6 months without deco...

Embodiment 3

[0049] Add 50 grams of methyl salicylate and 0.6 grams of alkylphenol formaldehyde resin polyoxyethylene ether (Handan Xindia Chemical Co., Ltd., Nongru 700#) into a three-necked flask, stir evenly, add 55 grams of water, stir and emulsify . Add 29.6 grams of hydroxylamine sulfate, after dissolving, add 95 grams of 40% sodium hydroxide solution dropwise, control the temperature of the reaction solution at 28-29° C. during the dropwise addition, and the pH value is not more than 12, after the dropwise addition (1.5 hours), Insulate and react for 3 hours, then raise the temperature to 40° C., and react for 3 hours. After completion of the reaction, the precipitated salt was removed by filtration to obtain a clear and transparent solution of sodium salicylhydroxamic acid. In terms of salicylhydroxamic acid, the content of salicylhydroxamic acid was 22.9%. The product is tracked by gas chromatography, and the product has good stability within 6 months without decomposition by-pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com