A kind of alkynylated neutral polymer bonding agent, preparation method and propellant

A polymer and bonding agent technology, applied in offensive equipment, non-explosive/non-thermal agent components, explosives, etc., can solve the problems of inability to further improve the mechanical properties of propellants, weak interactions, and inability to improve polymer chain interactions. , to achieve the effect of improving modulus and tensile strength, enhancing physical reinforcement, and improving modulus and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the neutral polymer bonding agent of alkynylation of the present invention specifically comprises the steps:

[0044] (1) According to the ratio of substances, add 1,000 to 10,000 parts of N,N-dimethylformamide (DMF), 1 to 10 parts of catalyst, 10 to 100 parts of terminal alkynyl alcohol, 50 to 80 parts °C and stirred to dissolve to obtain a mixed solution. The catalyst is one of triphenylbismuth, triethoxyphenylbismuth and organotin. The alkynyl alcohol is any one of 3-butyne-1-ol, 2-methyl-3-butyne 2-ol, propynyl alcohol or ethoxy propynyl alcohol or a mixture of any two.

[0045] (2) Add 10 to 100 parts of toluene diisocyanate (TDI) to the mixed solution under a nitrogen or inert gas atmosphere. The amount of the alkynyl alcohol is the same as that of the toluene diisocyanate. Reaction for 5-10 hours;

[0046] (3) Add 10 to 100 parts of neutral polymer bonding agent to the mixed solution in step (2), stir and dissolve, and continue to rea...

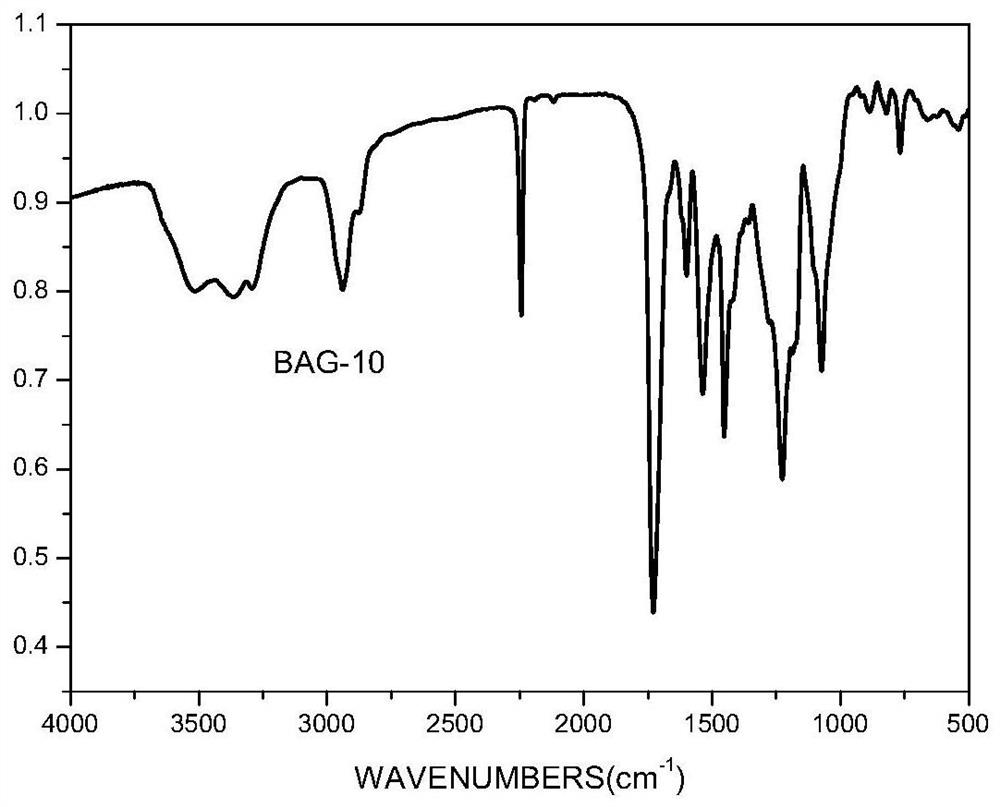

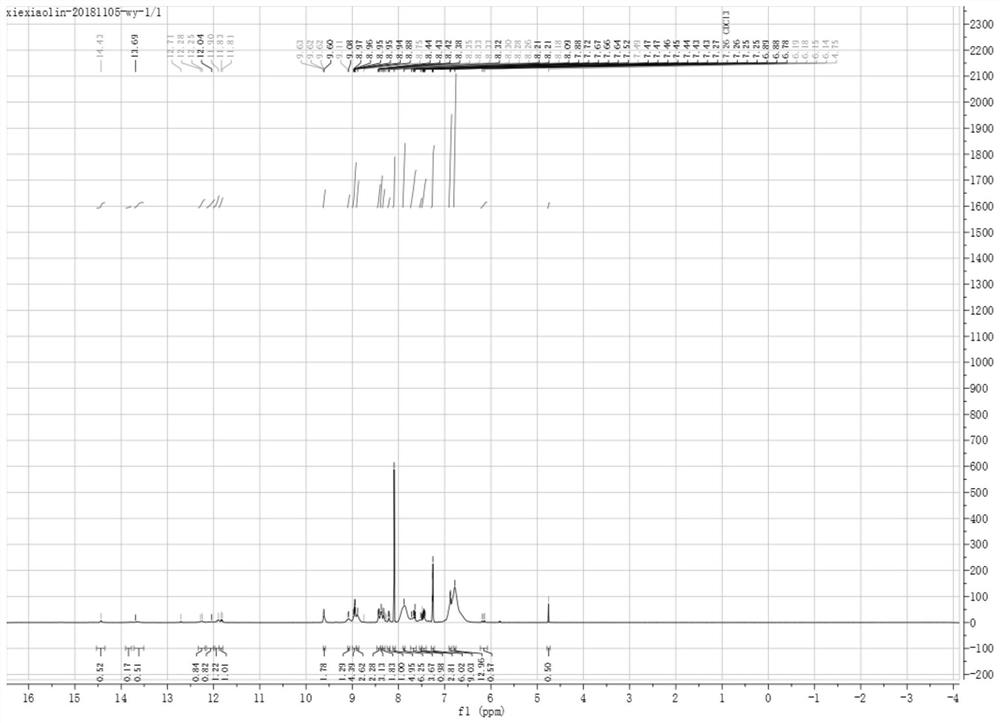

Embodiment 1

[0049] Select a three-necked flask (2L) equipped with magnetic stirring, reflux condenser, thermometer and addition funnel, etc., add 100ml DMF, 0.10g triethoxyphenyl bismuth to the four-necked flask under nitrogen atmosphere, and then add 2.0g triethoxyphenyl bismuth to the solution Ethoxypropynyl alcohol was stirred at 60°C for 30 minutes to dissolve to obtain a mixed solution. Then, 3.475g of toluene diisocyanate (TDI) was added to the above-mentioned mixed solution under an inert gas atmosphere, and reacted for 10 hours at 70°C; after that, 15.0g of neutral polymer bonding agent NPBA (Mn=2510, D: 1.45), stirred and dissolved, and continued to react for 20 hours at 60°C; after the reaction, the above-mentioned mixed solution was slowly added dropwise in 1000ml of glacial ethanol, and the alkynylated neutral polymer bonding agent generated by the reaction was obtained from glacial ethanol Precipitate out, vacuum filter, and use a large amount of ice ethanol to wash and filte...

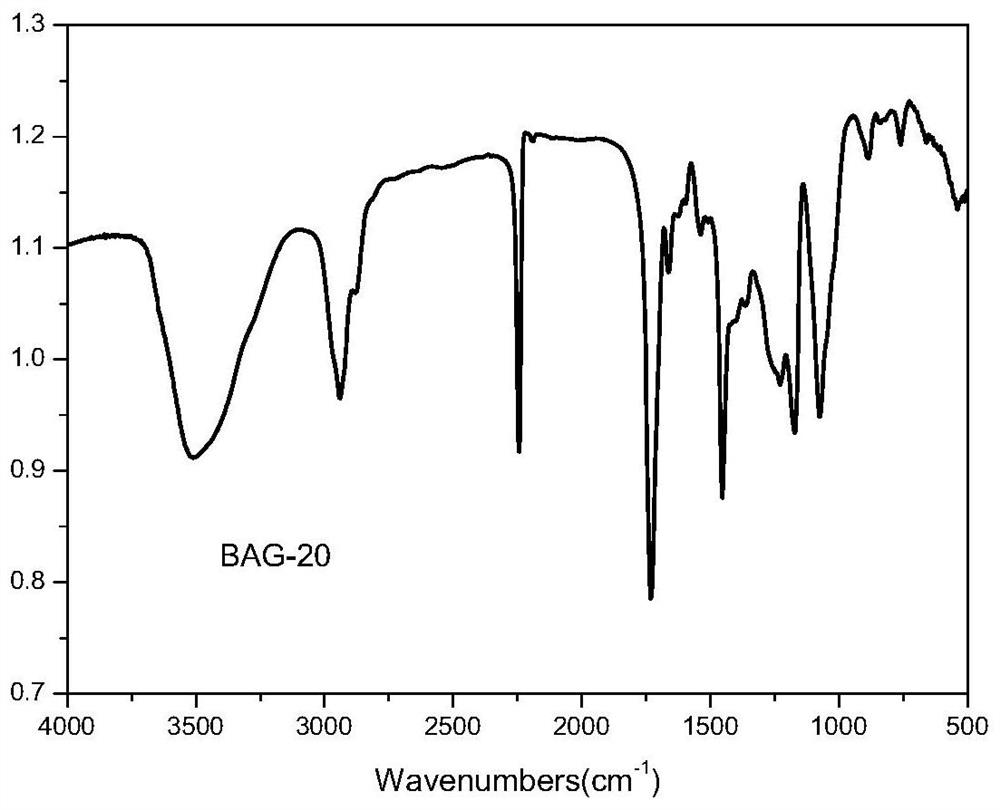

Embodiment 2

[0057] Select a three-necked flask (2L) equipped with magnetic stirring, reflux condenser, thermometer and addition funnel, etc., add 100ml DMF, 0.15g triphenylbismuth to the four-necked flask under nitrogen atmosphere, and then add 0.50g 3-butyl bismuth to the solution Alkyn-1-ol was dissolved by stirring at 80°C for 30 minutes to obtain a mixed solution. Then add 1.24g toluene diisocyanate (TDI) to the above-mentioned mixed solution under nitrogen or an inert gas atmosphere, and react for 10 hours at 70°C; after that, add 15.0g neutral polymer bonding agent NPBA (Mn= 2510, D: 1.45), stirred and dissolved, and continued to react at 80°C for 15 hours; after the reaction, the above mixed solution was slowly added dropwise to 2000ml ice methanol, and the alkynylated neutral polymer bonding agent generated by the reaction was from Precipitate in ice ethanol, vacuum filter, wash and filter the product with a large amount of ice methanol solution, and dry in vacuum to obtain alkyny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com