Method for comprehensively recycling carbon, iron, aluminum, zinc and lead from blast furnace gas sludge

A blast furnace gas mud and iron recovery technology, applied in the fields of iron, lead, comprehensive recycling of carbon, aluminum, and zinc, can solve the problems of difficulty in recovering aluminum and lead, low grade of iron concentrate, and low carbon recovery rate, etc. The effect of reducing process cost, reducing drug dosage and improving grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

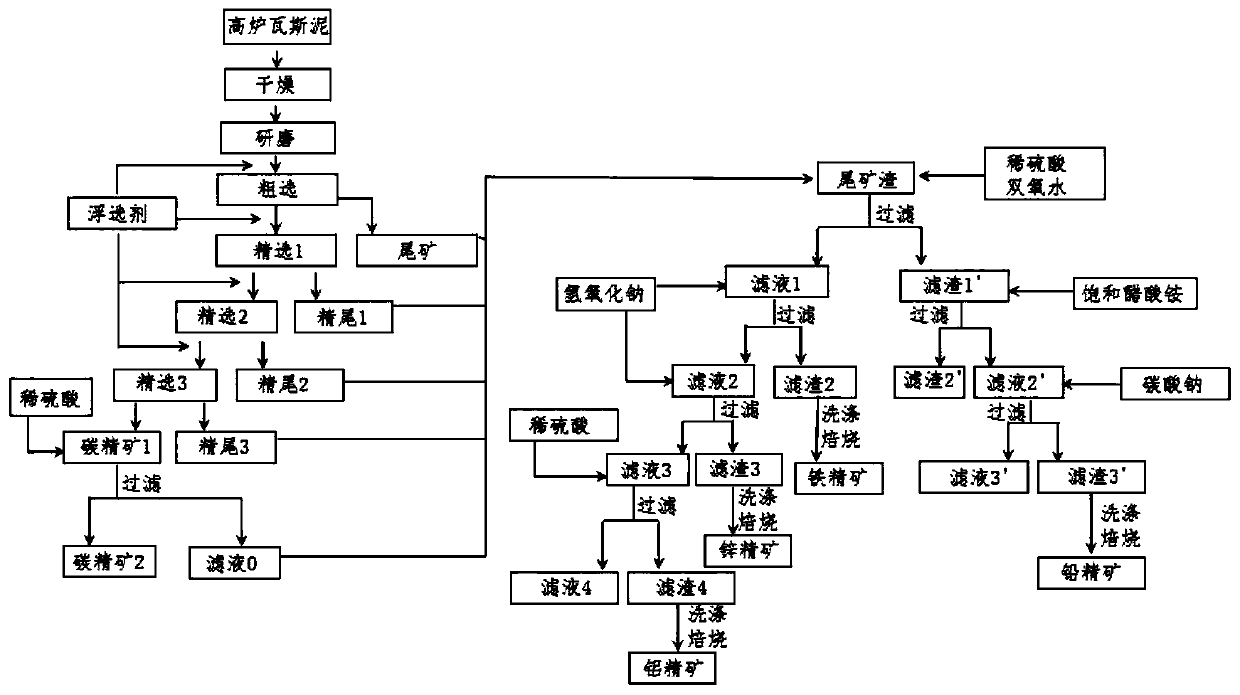

[0035] A method for comprehensive recovery and utilization of multiple valuable elements in blast furnace gas mud, the process flow chart is shown in figure 1 , including the following steps:

[0036] 1) Put the blast furnace gas mud into a drying oven, dry it at 120°C for 36 hours, and grind it with a planetary ball mill for 2 hours to obtain gas ash with a particle size of less than 0.1 μm;

[0037] 2) add water to the gas ash obtained in step 1) to make the slurry concentration 6wt%, stir evenly, add collector diesel oil and foaming agent 2# oil to the obtained slurry (the amount of collector relative to gas mud is 7wt%; The consumption of foaming agent relative to the gas mud is 4wt%) then add unslaked lime to adjust the pH value of the gained slurry to 11, carry out a rough separation three times to concentrate and collect carbon slurry and tailings; Drying under high temperature for 24 hours, then adding 5 times the dilute sulfuric acid with a mass concentration of carb...

Embodiment 2

[0049] A method for comprehensive recycling of multiple valuable elements in blast furnace gas mud, specifically comprising the following steps:

[0050] 1) Put the blast furnace gas mud into a drying oven, dry it at 120°C for 36 hours, and grind it with a planetary ball mill for 2 hours to obtain gas ash with a particle size of less than 0.1 μm;

[0051] 2) Add water to the gas ash obtained in step 1) to make the slurry concentration 6%, stir evenly, add collector diesel oil and foaming agent 2# oil to the obtained slurry, and the amount of collector relative to the gas mud is 7% by mass %; The amount of foaming agent relative to gas mud is 4% by mass fraction. Then add quicklime to adjust the pH value of the obtained slurry to 12, carry out a rough separation three times to collect the carbon slurry and tailings; filter the collected carbon slurry and dry it at 120°C for 24 hours, and then add 5 times the amount of carbon The mass concentration of ore mass is that the dilut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com