A high-throughput electrochemical sensor for microdroplets based on micropillar arrays

A microcolumn array, electrochemical technology, applied in the direction of material electrochemical variables, scientific instruments, material analysis through electromagnetic means, etc., can solve the problems of difficult detection implementation, lack of technical devices, etc., to solve the problem of large liquid volume and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

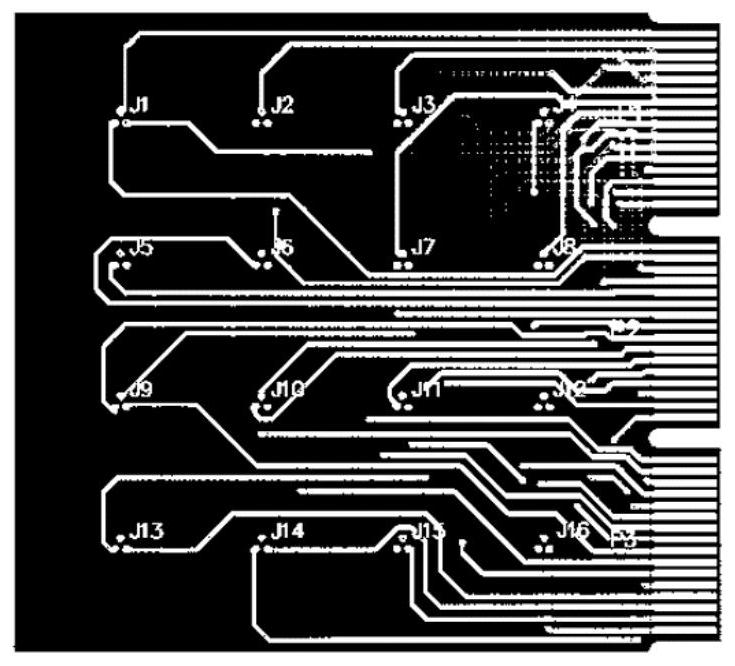

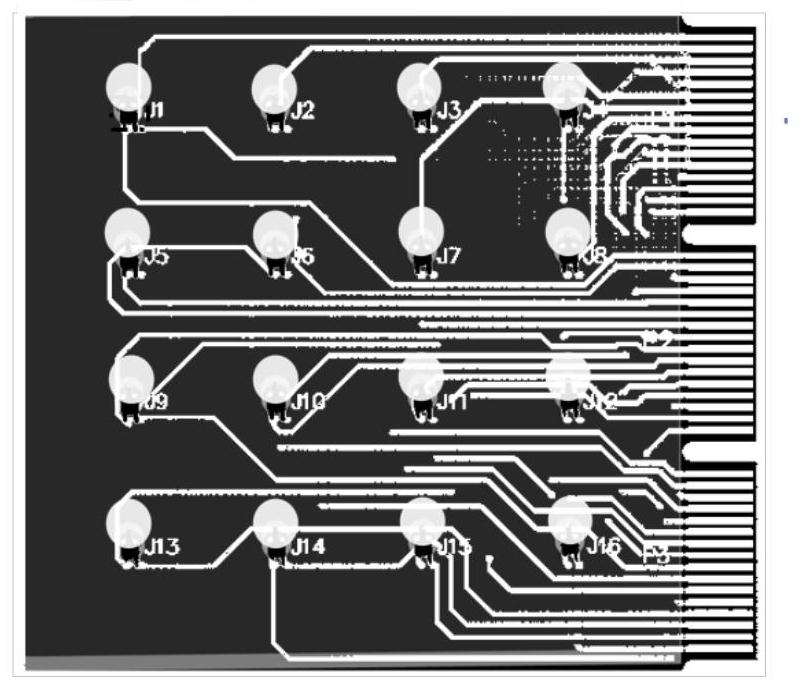

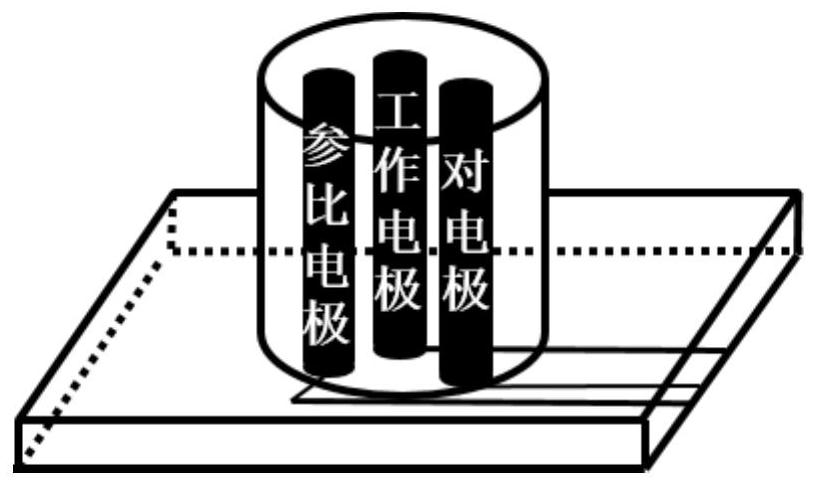

[0033] Step 1. Preparation of the microcolumn platform: the present invention takes the 3D printing polylactic acid template as an example, uses 3D printing technology to print out a polylactic acid template with a diameter of 1-4mm and a thickness of 1.5mm, cleans it with ethanol, and uses adhesive tape Seal one side of the template and paste it on the petri dish, mix PDMS with curing agent and vacuumize to remove air bubbles, then pour it into the petri dish, and after curing in an oven at 50-60°C for 4-5 hours, carefully peel off the template to obtain a microcolumn array platform.

[0034] Step 2. Electrode wire integration: Soak the microcolumn platform obtained in step 1 and the purchased gold, silver and platinum electrode wires in ethanol for 10-15 minutes, take them out and dry them, and soak the silver wires in saturated sodium chloride After 1-2 hours in the solution, take it out as a reference electrode. Three kinds of electrodes are inserted into the microcolumn ...

Embodiment 1

[0038] A method for preparing a micro-droplet high-throughput electrochemical sensor based on a micro-column array, comprising:

[0039] Step 1. Preparation of microcolumn platform: The present invention takes 3D printing polylactic acid template as an example, designs a model with a cylindrical groove array through 3D Max, prints out the designed polylactic acid model by using 3D printing technology, and uses the model to Soak in ethanol and ultrasonic for 5-10 minutes to clean thoroughly, seal one side of the model with tape so that PDMS can only enter the hollow cylinder from one side, and then fix the template on the Petri dish with double-sided adhesive to avoid floating. Mix PDMS and curing agent evenly at a ratio of 15:1, place it in a vacuum oven at 60°C for 10-15 minutes to remove air bubbles in the mixture, and pour it evenly on the polylactic acid model, and let it stand for 4-5 minutes to remove the bubbles generated during pouring. bubbles, and then placed in a 60...

Embodiment 2

[0043] Analysis of micro-droplet carrying capacity of micro-column platform, including:

[0044] Step 1. The influence of the degree of inclination of the microcolumn on the fixation of the droplet: the droplet is added to the surface of the microcolumn, and the droplet will not fall off when the microcolumn platform is tilted to 45°, 90° and upside down, indicating that the microcolumn Droplets can be well fixed for detection.

[0045] Step 2. Add the droplet on the surface of the microcolumn, and moderately stretch, twist and bend the microcolumn platform, and the droplet can be stably maintained on the surface of the microcolumn, which shows that the microcolumn platform has good flexibility and Very well fixed droplets for detection.

[0046] Step 3. Analysis of the carrying capacity of the microcolumns on different types of solutions: water, PBS, serum, milk, coffee, dyes, sweat, 1M hydrochloric acid and 1M sodium hydroxide and other solutions were added dropwise to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com