Preparation method and application of a core-shell structure composite optoelectronic material

A technology of core-shell structure and photoelectric materials, which is applied in chemical instruments and methods, electrodes, electrolytic components, etc., can solve the problems of short hole diffusion distance, low electron mobility, and limitation of photogenerated electron-hole separation and transfer. Achieve the effects of simple preparation method, excellent photoelectric performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

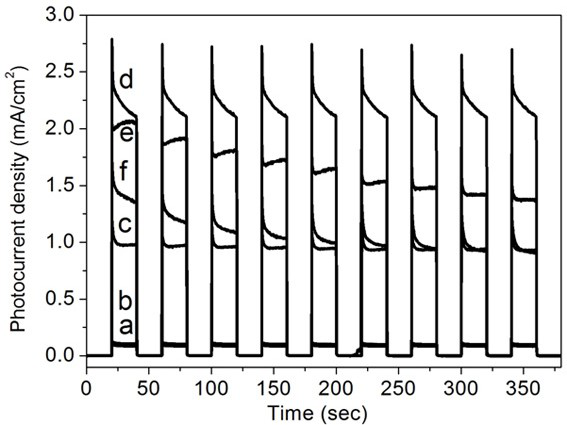

Embodiment 1

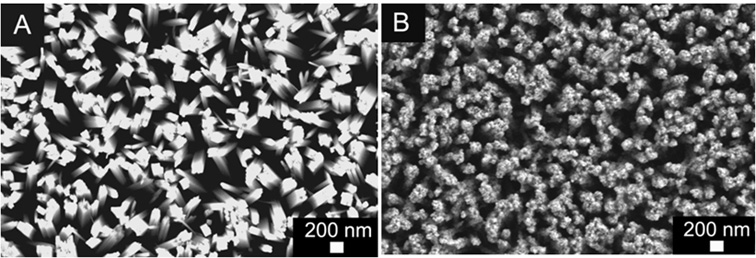

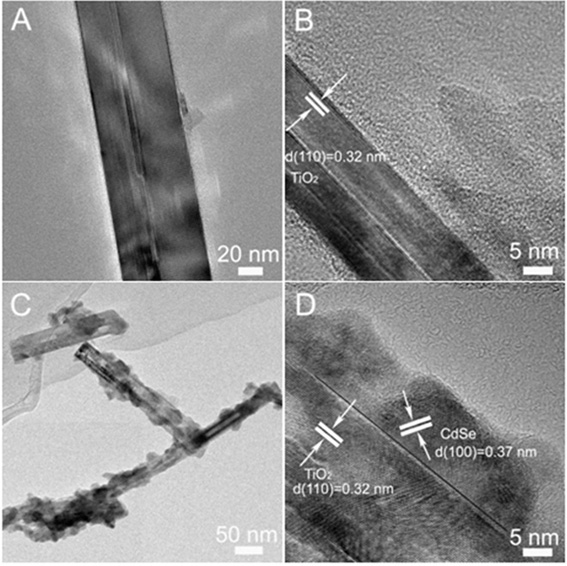

[0023] Example 1 One-dimensional TiO 2 Fabrication of Nanorod Arrays

[0024] The FTO conductive glass was placed in acetone, absolute ethanol and deionized water in sequence, ultrasonically cleaned for 20 min respectively, and dried for later use after cleaning; then 15 mL of PTFE with a volume concentration of 37% HCl solution and 15 mL of deionized water, stirred at room temperature for 5 min to make it evenly mixed, then added 1.5 mmol of tetrabutyl titanate, and continued to stir for 5 min; place the cleaned FTO conductive glass obliquely in the reaction kettle In the process, make the conductive surface of FTO face up, and then move the reactor into a 170°C oven for hydrothermal reaction for 5 hours. After the reaction, take out the FTO conductive glass, rinse it with deionized water, dry it at room temperature, and place it in the muffle Calcined in a furnace at 400 °C for 2 h to obtain one-dimensional rutile TiO 2 Nanorod array, number 1.

Embodiment 2

[0026] 1) One-dimensional TiO 2 Fabrication of Nanorod Arrays

[0027] The FTO conductive glass was placed in acetone, absolute ethanol and deionized water in sequence, ultrasonically cleaned for 20 min respectively, and dried for later use after cleaning; then 15 mL of PTFE with a volume concentration of 37% was added to a 50 mL polytetrafluoroethylene reactor. HCl solution and 15 mL of deionized water, stirred at room temperature for 5 min to make it evenly mixed, then added 1.5 mmol of tetrabutyl titanate, and continued to stir for 5 min; the cleaned FTO conductive glass was placed obliquely in the reaction kettle In the process, make the conductive surface of FTO face up, and then move the reactor into a 170°C oven for hydrothermal reaction for 5 hours. After the reaction, take out the FTO conductive glass, rinse it with deionized water, dry it at room temperature, and place it in the muffle Calcined in a furnace at 400 °C for 2 h to obtain one-dimensional rutile TiO 2 n...

Embodiment 3

[0031] 1) One-dimensional TiO 2 Fabrication of Nanorod Arrays

[0032] The FTO conductive glass was placed in acetone, absolute ethanol and deionized water in sequence, ultrasonically cleaned for 20 min respectively, and dried for later use after cleaning; then 15 mL of PTFE with a volume concentration of 37% was added to a 50 mL polytetrafluoroethylene reactor. HCl solution and 15 mL of deionized water, stirred at room temperature for 5 min to make it evenly mixed, then added 1.5 mmol of tetrabutyl titanate, and continued to stir for 5 min; the cleaned FTO conductive glass was placed obliquely in the reaction kettle In the process, make the conductive surface of FTO face up, and then move the reactor into a 180°C oven for hydrothermal reaction for 3 hours. After the reaction, take out the FTO conductive glass, rinse it with deionized water, dry it at room temperature, and place it in the muffle Calcined in a furnace at 500 °C for 1 h to obtain one-dimensional rutile TiO 2 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com