Recycled composite concrete pavement and preparation method thereof

A technology for concrete pavement and rejuvenating agent, applied in the direction of roads, roads, road repair, etc., can solve the problems of disappearance, long traffic closure time, and weakened performance of composite concrete flexibility, to improve high temperature rutting resistance and durability, overcome the The effect of easy temperature shrinkage cracking and improving road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

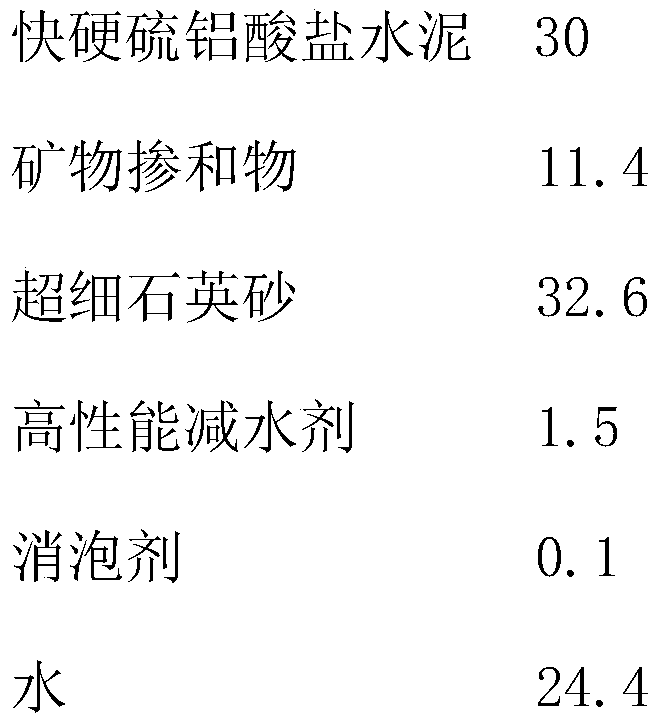

Embodiment 1

[0030] Raw materials for recycled composite concrete pavement include: recycled asphalt pavement materials and cement-based mortar.

[0031] Recycled asphalt pavement materials are calculated in parts by weight of each component, including:

[0032] Recycled asphalt pavement material 90

[0033] New aggregate 9

[0034] Regenerant 0.4

[0035] Tackifier 0.6

[0036] The recycled asphalt pavement material is the pavement milling material of Shenshan Expressway, and the original pavement asphalt is SBS modified asphalt.

[0037] Recycled asphalt pavement materials are divided into three grades according to particle size, with particle sizes ranging from 0mm to 5mm, 5mm to 10mm and 10mm to 20mm.

[0038] The new aggregate has two specifications of 5mm-10mm and 10mm-20mm.

[0039] The regeneration agent is an aromatic solvent oil, selected from the product of Gerkelin Trading (Shanghai) Co., Ltd., and the brand name is GRAR01.

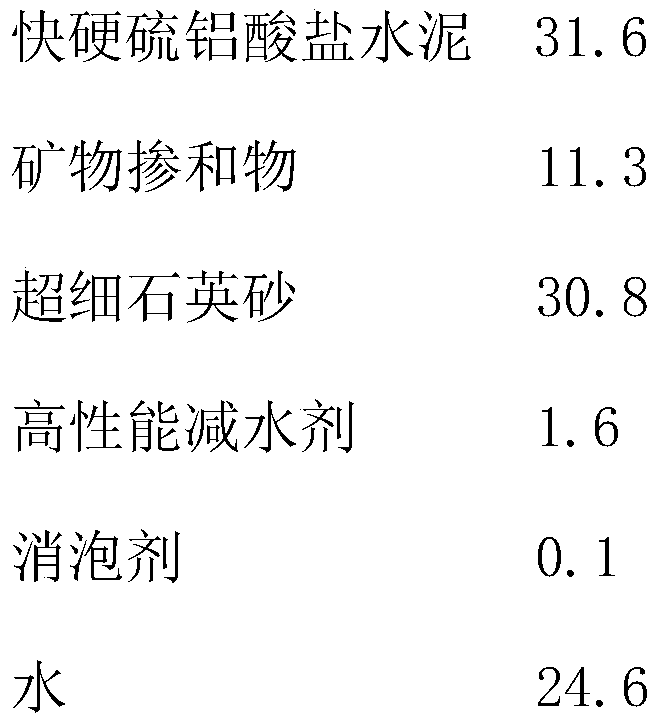

Embodiment 2

[0054] Recycled asphalt pavement materials are calculated in parts by weight of each component, including:

[0055] Recycling Asphalt Pavement Material 94

[0056] New aggregate 5

[0057] Regenerant 0.5

[0058] Tackifier 0.5

[0059] The recycled asphalt pavement material is the pavement milling material of Shenshan Expressway, and the original pavement asphalt is SBS modified asphalt.

[0060] Recycled asphalt pavement materials are divided into three grades according to particle size, with particle sizes of 5mm-10mm and 10mm-20mm.

[0061] The new aggregate has two specifications of 0mm-5mm and 5mm-10mm.

[0062] The regeneration agent is an aromatic solvent oil, selected from the product of Gerkelin Trading (Shanghai) Co., Ltd., and the brand name is GRAR01.

[0063] The tackifier is terpene resin, the product of Shanghai Zhengshang Chemical Technology Co., Ltd., the brand is 803L. The compacted porosity of recycled asphalt pavement materials was tested according to...

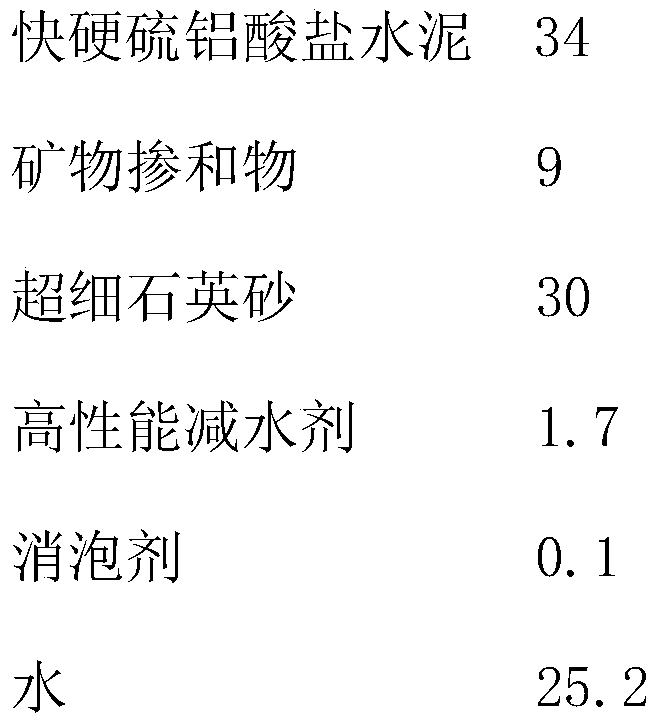

Embodiment 3

[0075] Recycled asphalt pavement materials are calculated in parts by weight of each component, including:

[0076] Recycled asphalt pavement material 100

[0077] Regenerant 0.6

[0078] Tackifier 0.4

[0079] The recycled asphalt pavement material is the pavement milling material of Shenshan Expressway, and the original pavement asphalt is SBS modified asphalt.

[0080] Recycled asphalt pavement materials are divided into three grades according to particle size, with particle sizes of 5mm-10mm and 10mm-20mm.

[0081] The regeneration agent is an aromatic solvent oil, selected from the product of Gerkelin Trading (Shanghai) Co., Ltd., and the brand name is GRAR01.

[0082] The tackifier is rosin resin, selected from Shangrao Henglin Resin Co., Ltd., the brand is 138, and the softening point is 80°C to 100°C.

[0083] The compacted porosity of recycled asphalt pavement materials was tested according to the provisions of T0708-2011 in the "Test Regulations for Asphalt and A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com